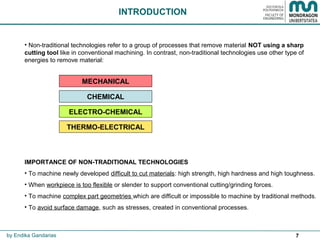

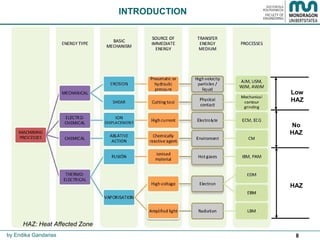

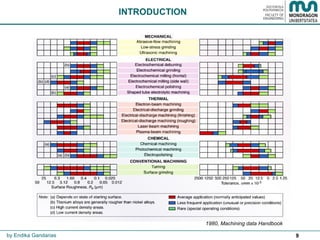

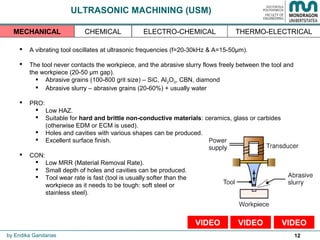

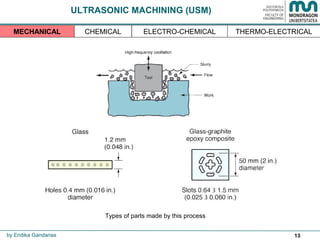

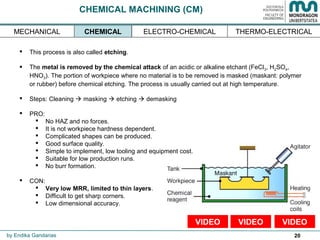

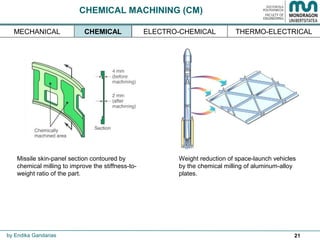

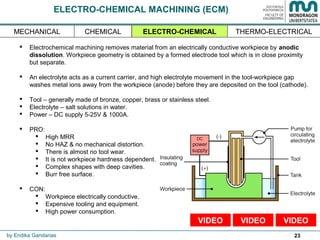

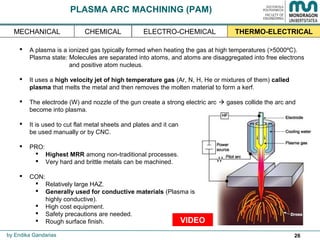

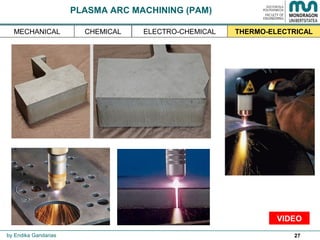

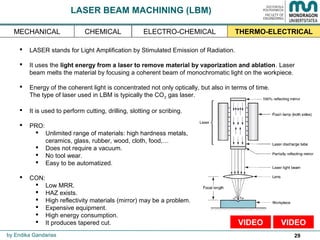

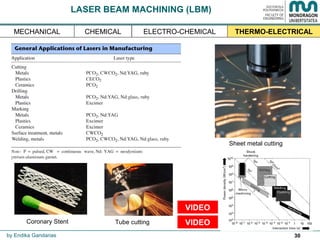

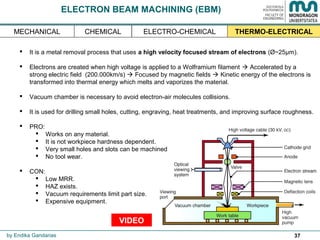

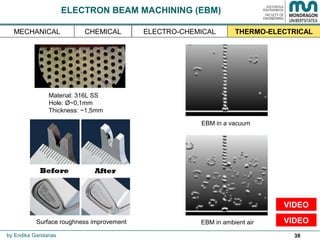

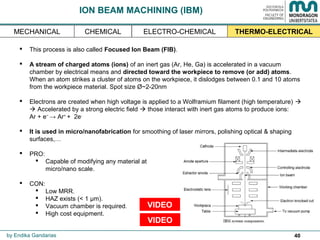

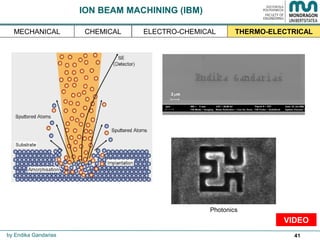

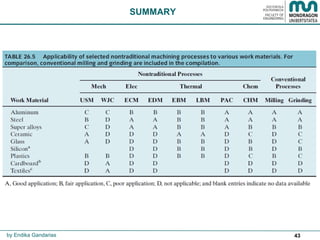

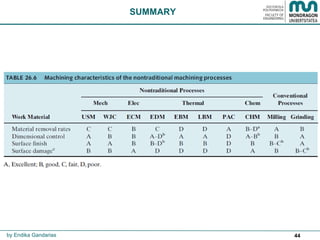

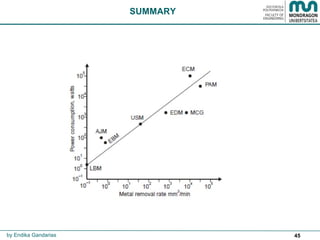

The document provides an overview of non-traditional machining technologies used for material removal, emphasizing their applications for hard, brittle, or complex materials. It details various methods including ultrasonic, jet, chemical, electro-chemical, plasma arc, laser beam, electrical discharge, electron beam, and ion beam machining, each with their respective advantages and disadvantages. A summary and glossary are also included to assist with understanding the terms and concepts discussed.