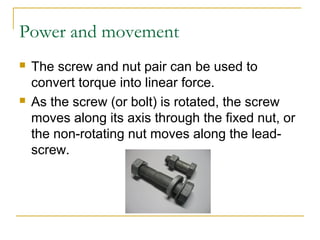

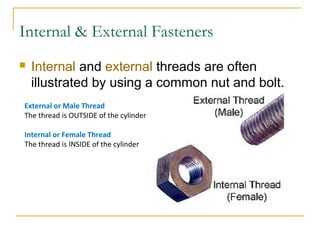

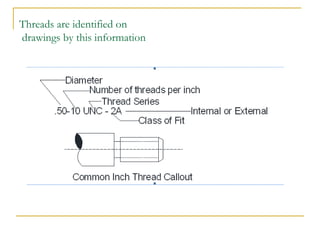

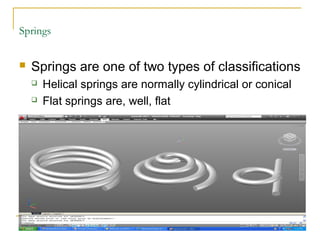

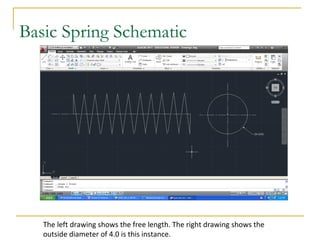

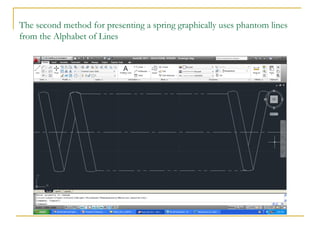

This document provides information on different types of fasteners and springs. It discusses permanent and temporary fasteners, as well as threaded and non-threaded types. Key fastener details like diameter, thread type, class of fit, and standards are defined. It also outlines the purpose of different spring types and important spring dimensions like free length and spring rate that need to be specified.