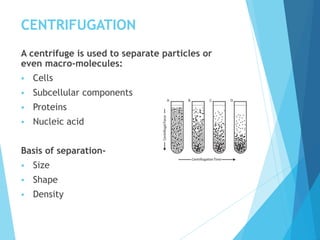

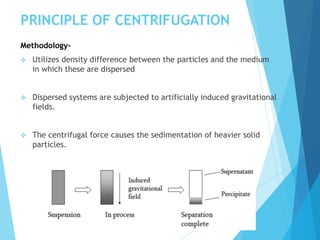

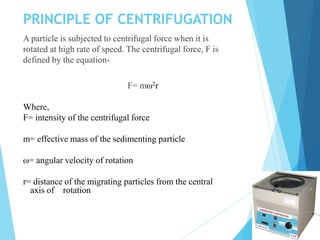

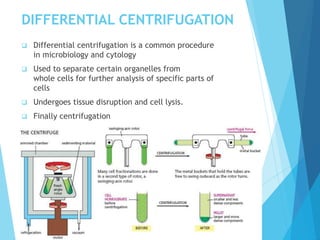

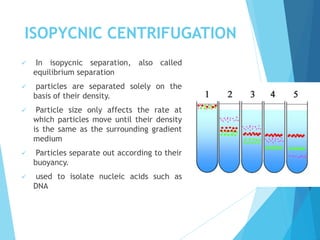

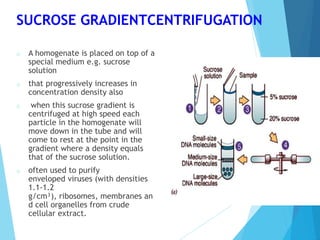

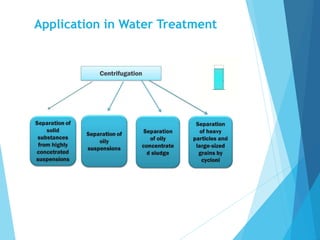

Centrifugation is a process that uses centrifugal force to separate particles or molecules based on their size, shape, or density. It involves spinning a sample in a centrifuge to separate it into its components. There are various types of centrifugation classified based on speed, temperature, or separation method including differential, isopycnic, sucrose gradient, and ultracentrifugation. Centrifugation has many applications in industries like pharmaceuticals, water treatment, and oil extraction as well as in research areas like biochemistry and molecular biology.