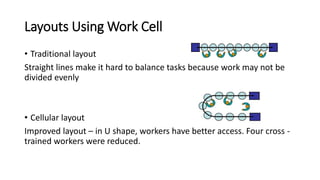

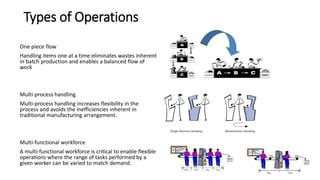

Cellular manufacturing is an approach where equipment and workstations are arranged based on groups of similar manufacturing processes located close together. This reduces cycle times and inventories to meet market demands. Traditional straight line layouts can imbalance tasks, while cellular U-shaped layouts improve worker access. One-piece flow, multi-process handling, and multi-functional workforces increase flexibility. Layouts should minimize transit time between workstations by keeping them close together in linear order. This can save companies millions per year by reducing unnecessary operator travel time. Cellular manufacturing advantages include reduced inventory/space needs and costs as well as increased productivity.