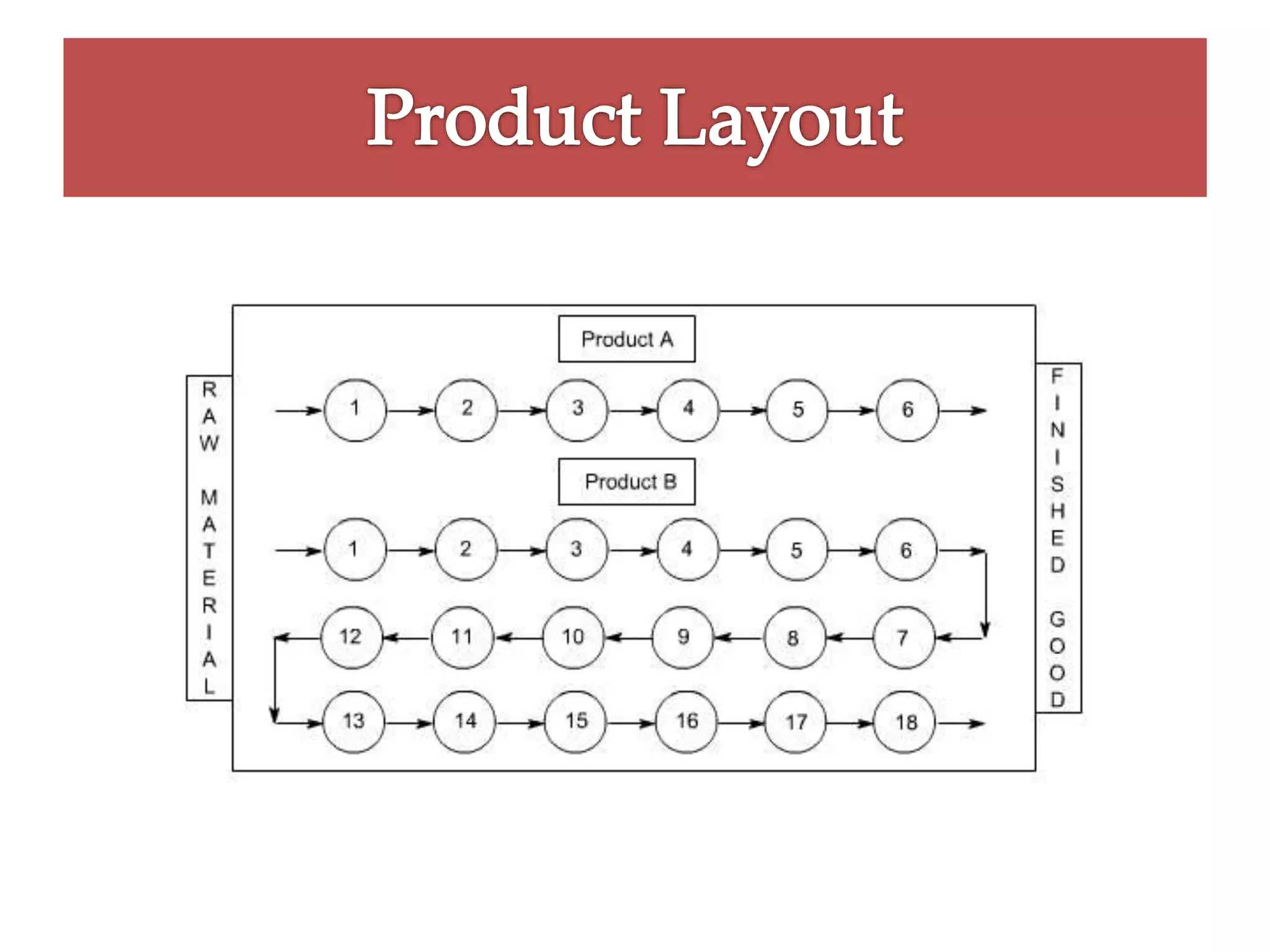

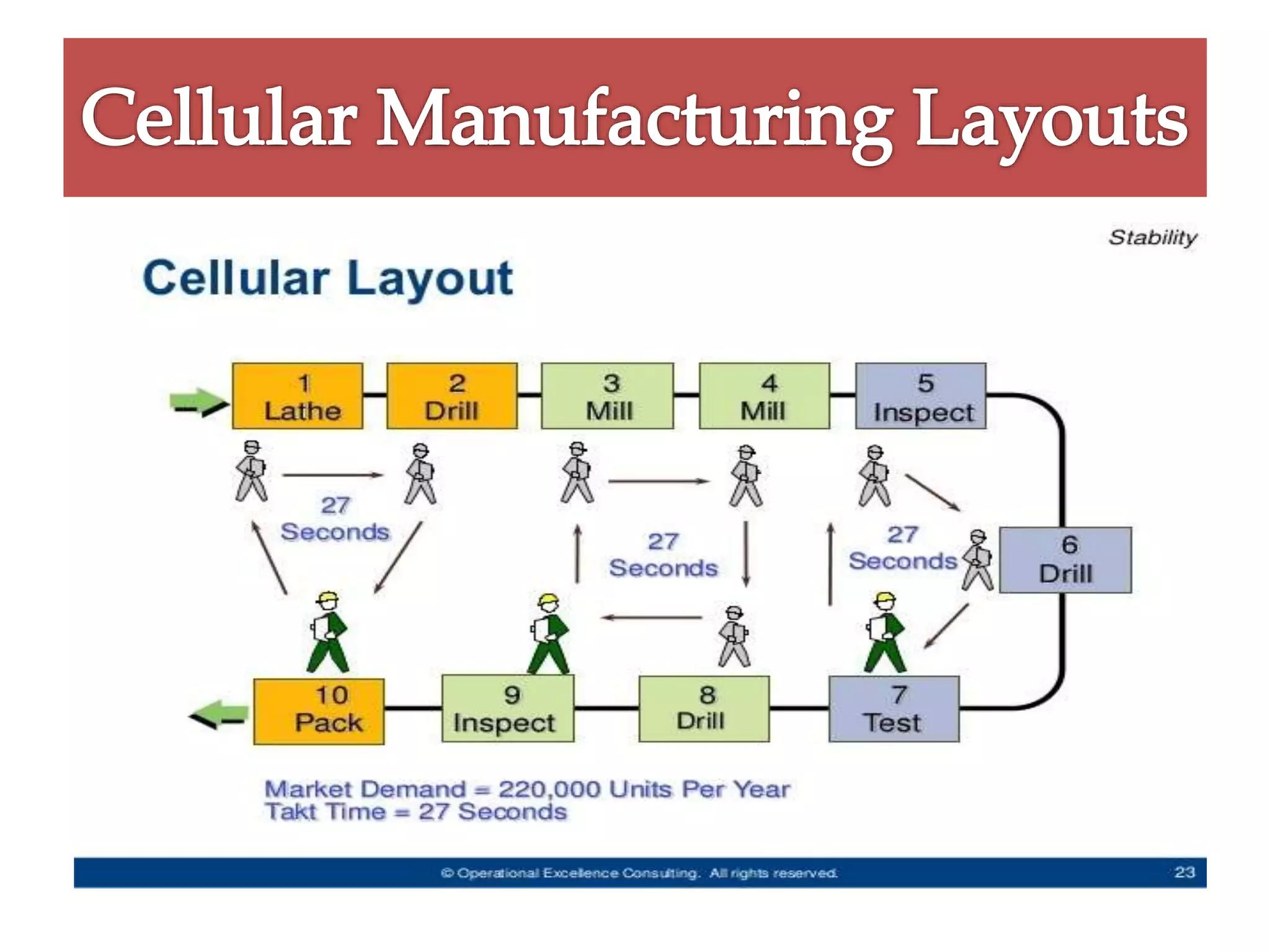

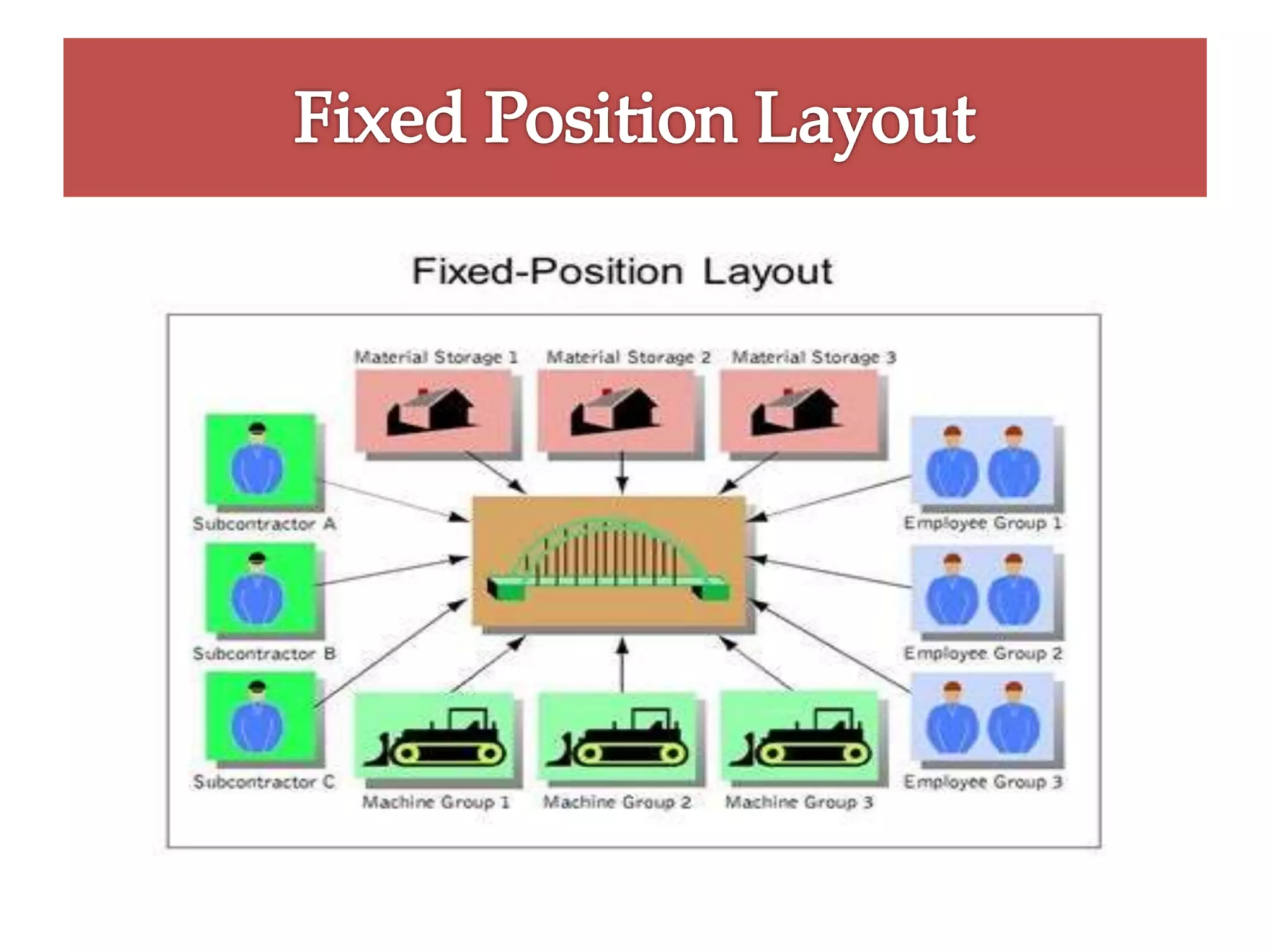

The document discusses various types of manufacturing layouts, including process, product, cellular, and fixed position layouts, highlighting their advantages and disadvantages in terms of material handling, space utilization, worker skill requirements, and flexibility. It notes how process layouts offer better equipment utilization and quality but require more space and skilled workers, while product layouts provide efficiency but can lead to excessive idle time and difficulties in scaling production. Hybrid layouts are also mentioned as a combination of processes, demonstrating that most manufacturing facilities incorporate multiple layout types.