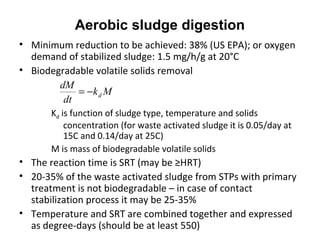

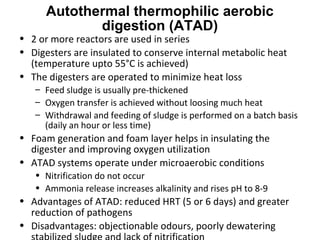

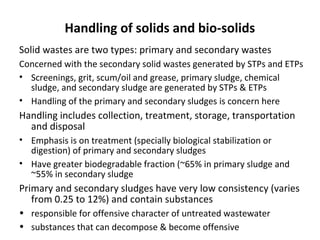

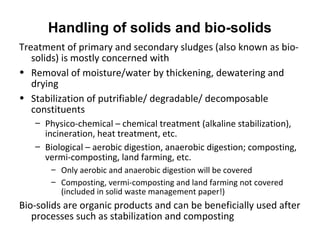

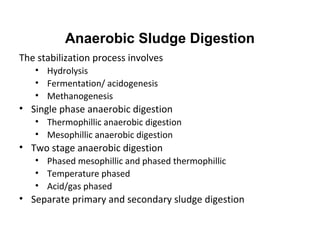

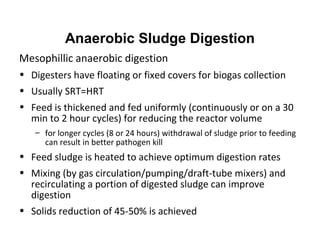

The document outlines the processes involved in the handling and biological digestion of solid wastes, specifically primary and secondary sludges generated by sewage treatment plants. It details various methods of sludge treatment, including anaerobic and aerobic digestion, their advantages and disadvantages, and factors influencing their efficiency. Additionally, it discusses the performance characteristics and design considerations of different anaerobic digesters, including heating, mixing, and biogas production.

![• Estimating volatile solids destruction

Vd is percent volatile solids destructed

• Alkalinity and volatile fatty acids content are usually checked

as a measure of stability of the digestion process

• Quantity of methane gas generated can be calculated by

Vmethane is volume of methane in m3

at 0°C and 1 atmos

S0 and Se are expressed as bCOD (I kg of bCOD

theoretically generates 0.35 m3

of methane)

Px is net mass of cell biomass produced

Typical Y and kd values are 0.05 to 0.1 and 0.02 to 0.04

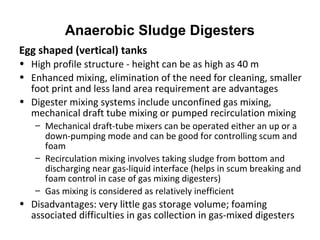

Design of Anaerobic Sludge Digester

9.18)ln(7.13 += desd SRTV

[ ]xeCH PSSQV 42.1)(35.0 04

−−=

SRTk

SSYQ

P

d

e

x

.1

)( 0

+

−

=](https://image.slidesharecdn.com/biologicalsludgedigestion-160429185256/85/Biological-sludge-digestion-23-320.jpg)