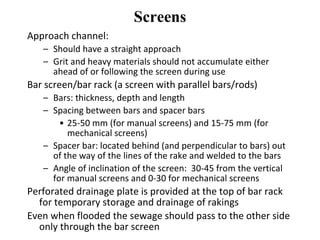

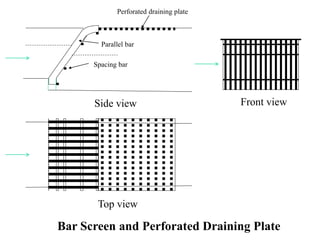

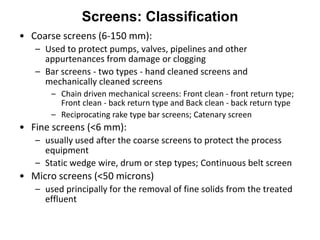

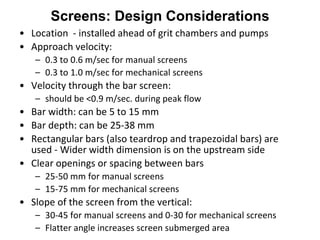

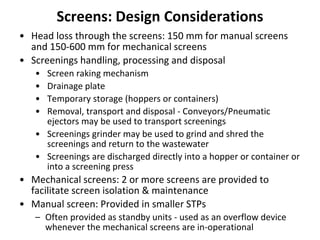

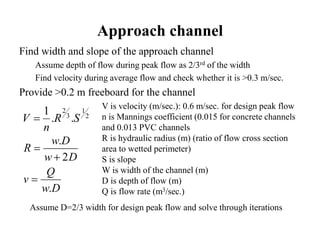

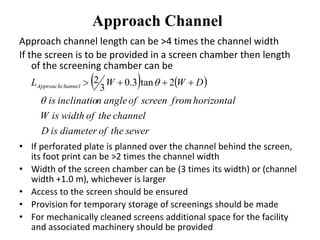

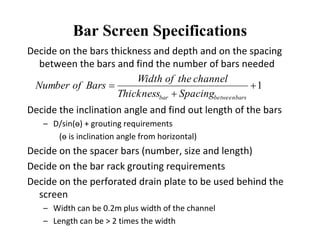

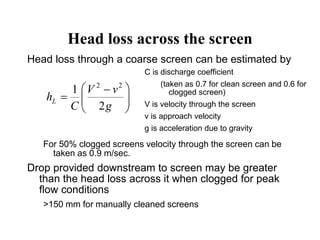

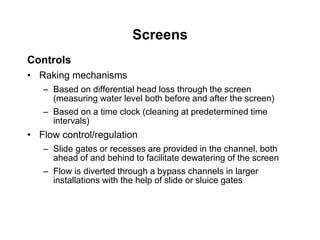

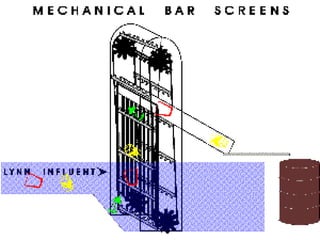

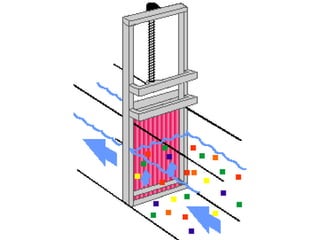

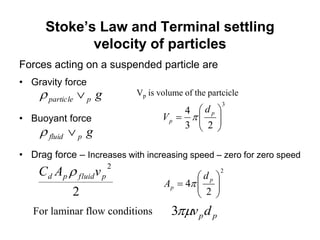

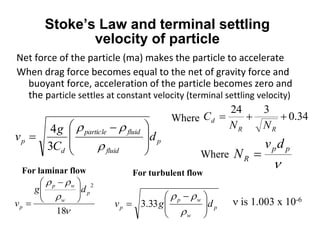

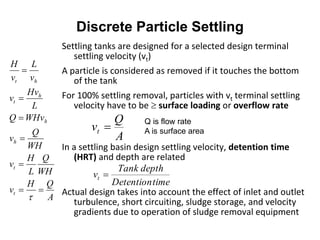

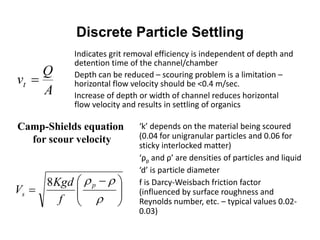

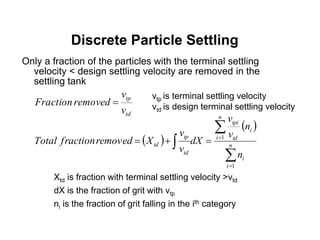

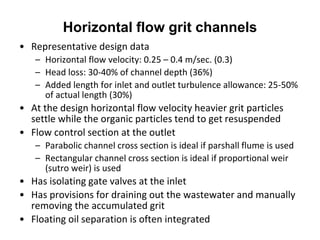

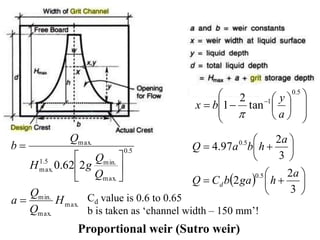

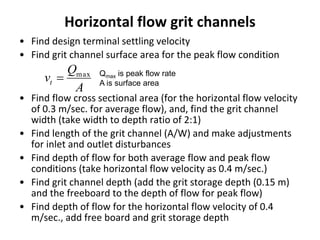

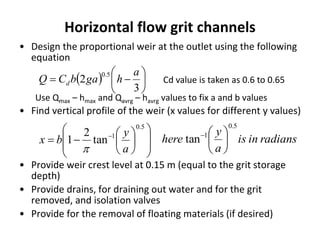

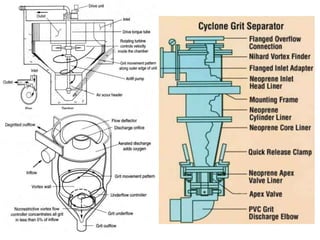

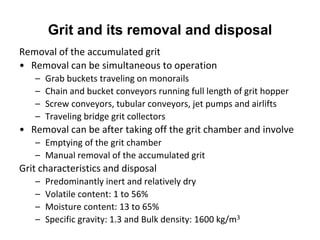

The document discusses preliminary treatment units for sewage treatment plants, focusing on bar screens and grit separators. It provides details on the components, design considerations, and operating principles of bar screens including bar rack specifications, head loss calculations, and screen classifications. It also covers grit chamber types, Stoke's law for particle settling velocities, discrete particle settling calculations, and design of horizontal flow grit channels. Key aspects addressed are screen approach channel design, screen raking mechanisms, and grit removal to protect equipment from abrasion.