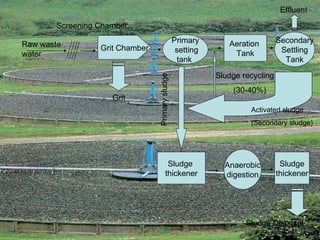

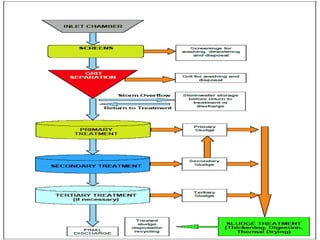

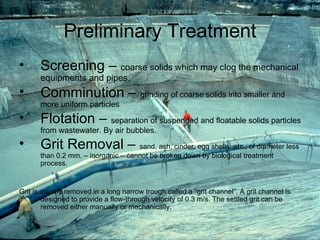

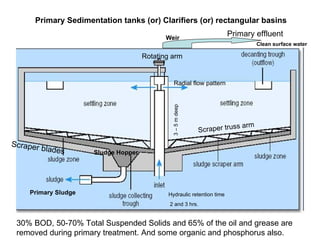

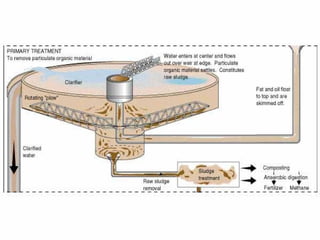

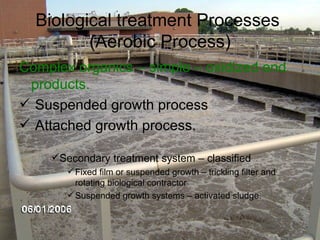

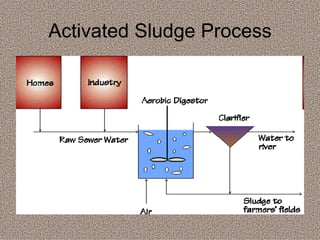

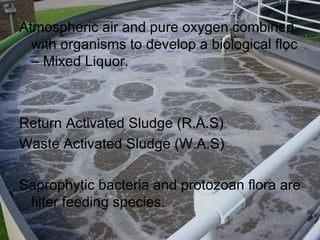

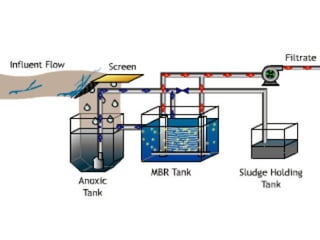

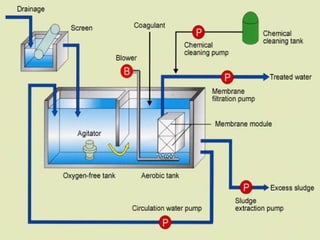

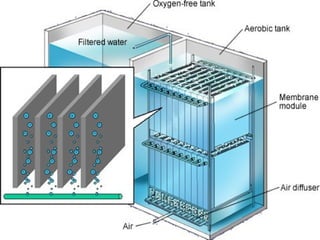

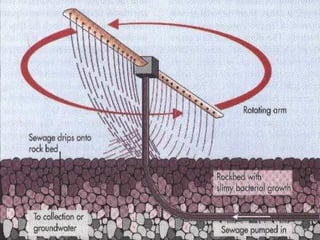

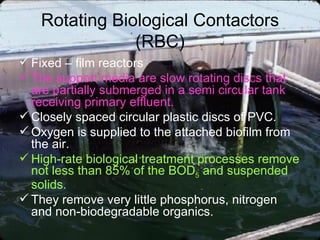

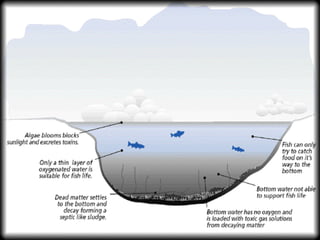

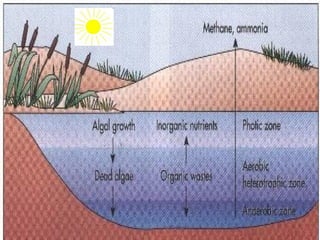

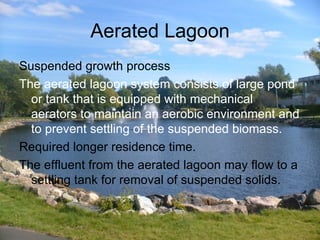

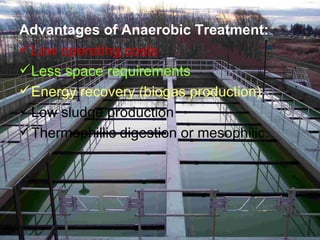

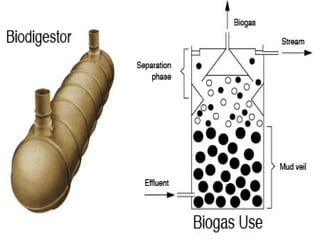

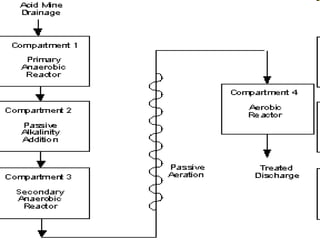

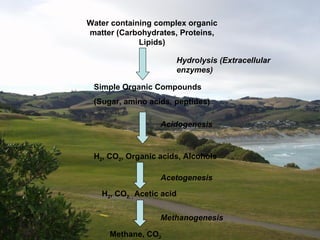

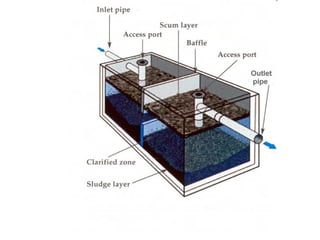

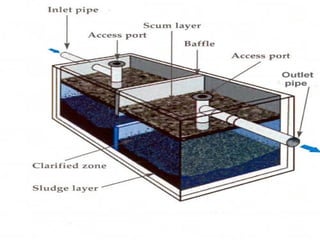

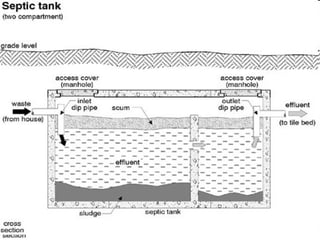

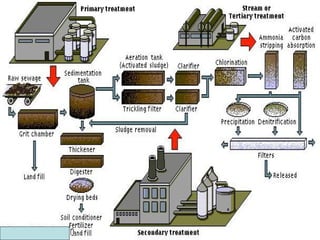

The document outlines wastewater treatment processes, including physical, chemical, and biological operations across four treatment levels: preliminary, primary, secondary, and tertiary. It details various treatment methods, such as screening, sedimentation, and biological processes like activated sludge and anaerobic digestion, along with their benefits and the operational principles involved. The tertiary treatment focuses on further purification, including disinfection and nutrient removal, to polish effluent before discharge.