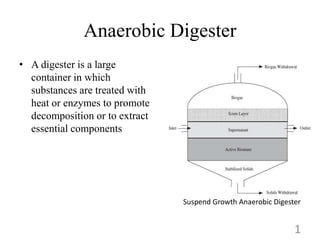

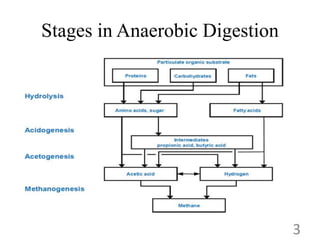

The document discusses anaerobic digestion, which is the decomposition of organic matter by microorganisms in the absence of oxygen. It occurs in four stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. The document outlines the stages and factors that affect the anaerobic digestion process, such as temperature, pH, nutrients, mixing, and seeding. Anaerobic digestion produces methane gas and reduces volatile solids in sludge while advantages include using the biogas as fuel and easier dewatering of the treated sludge. However, it also has disadvantages like needing constant supervision and being difficult to control.