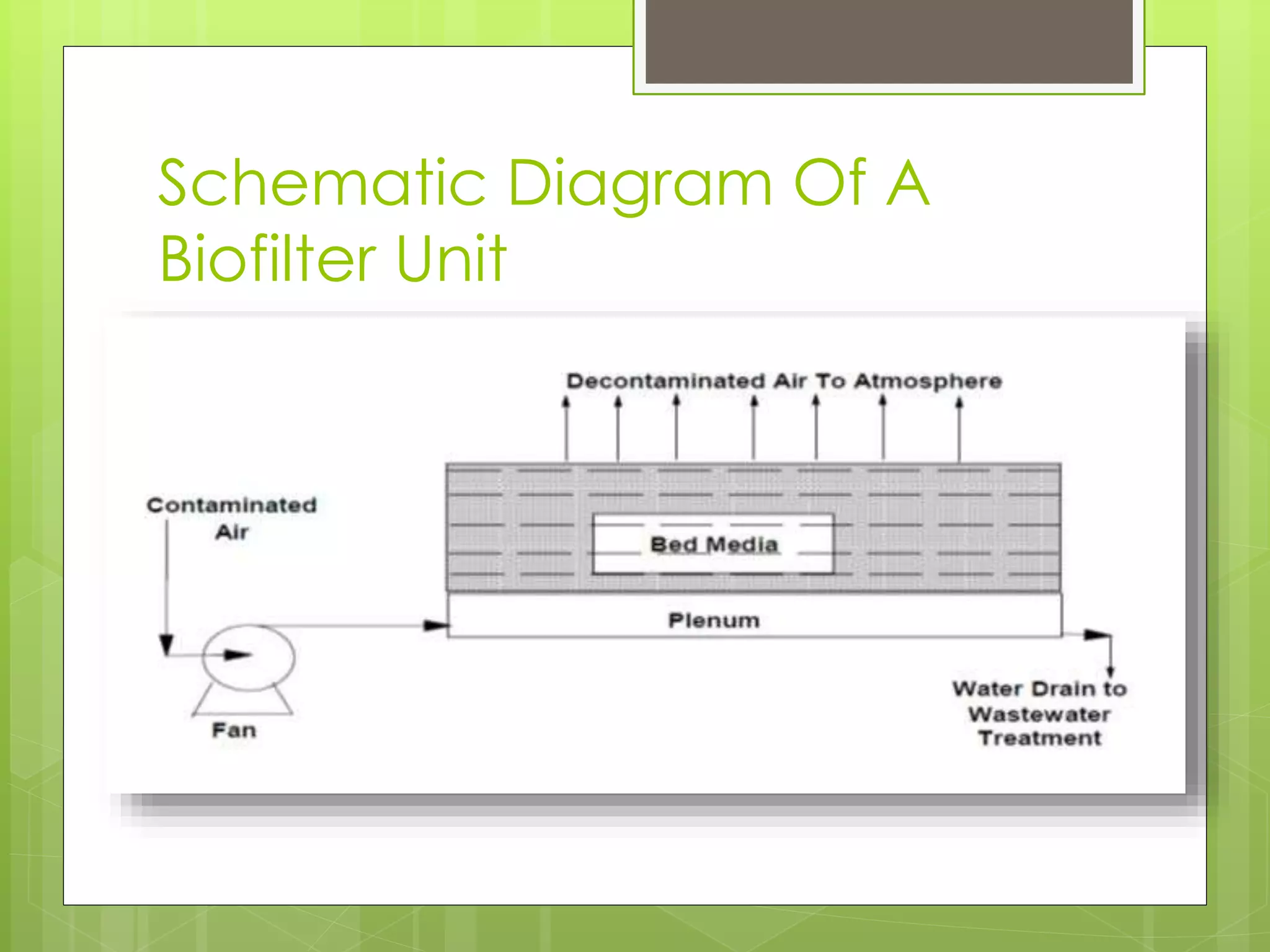

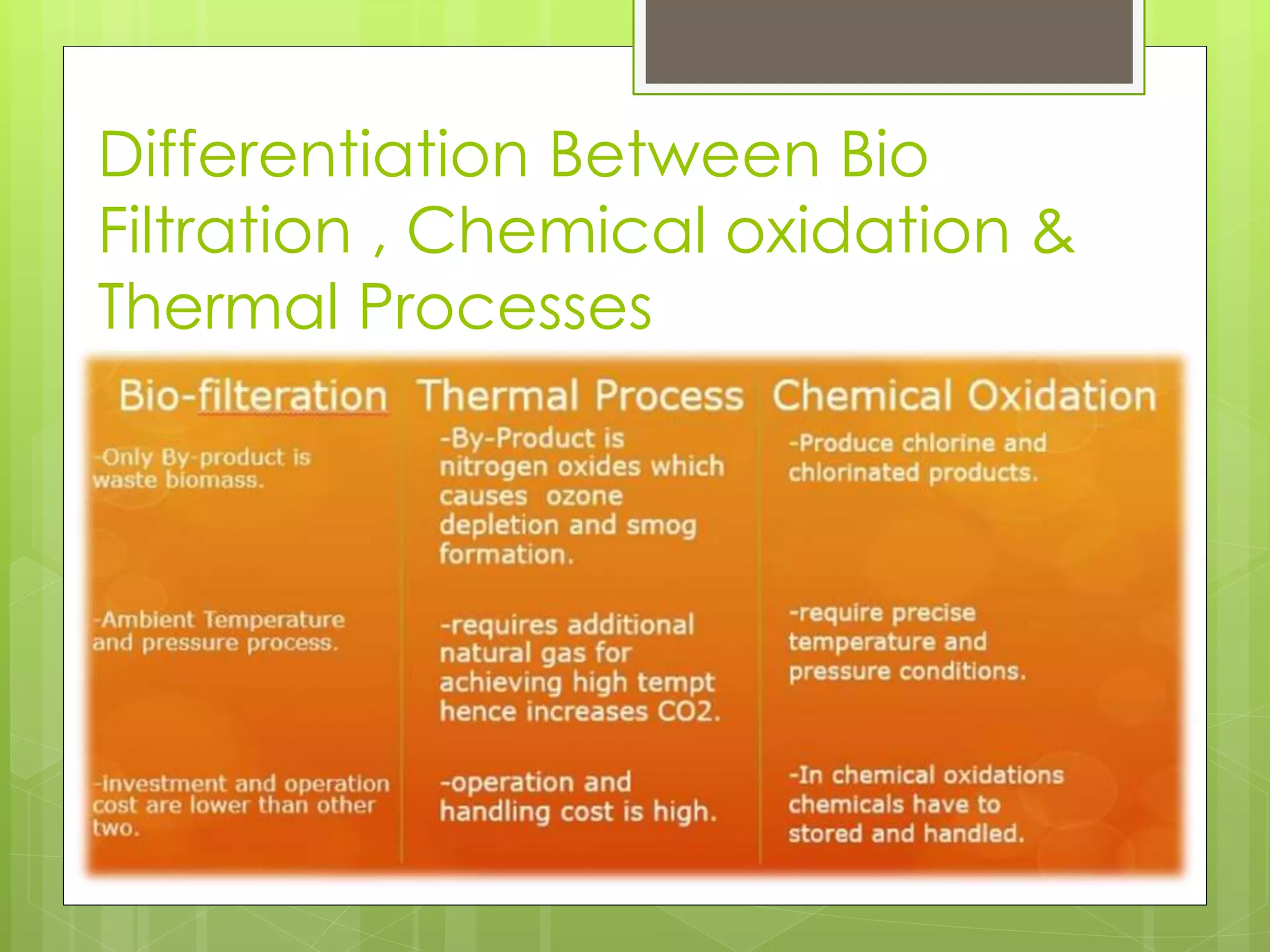

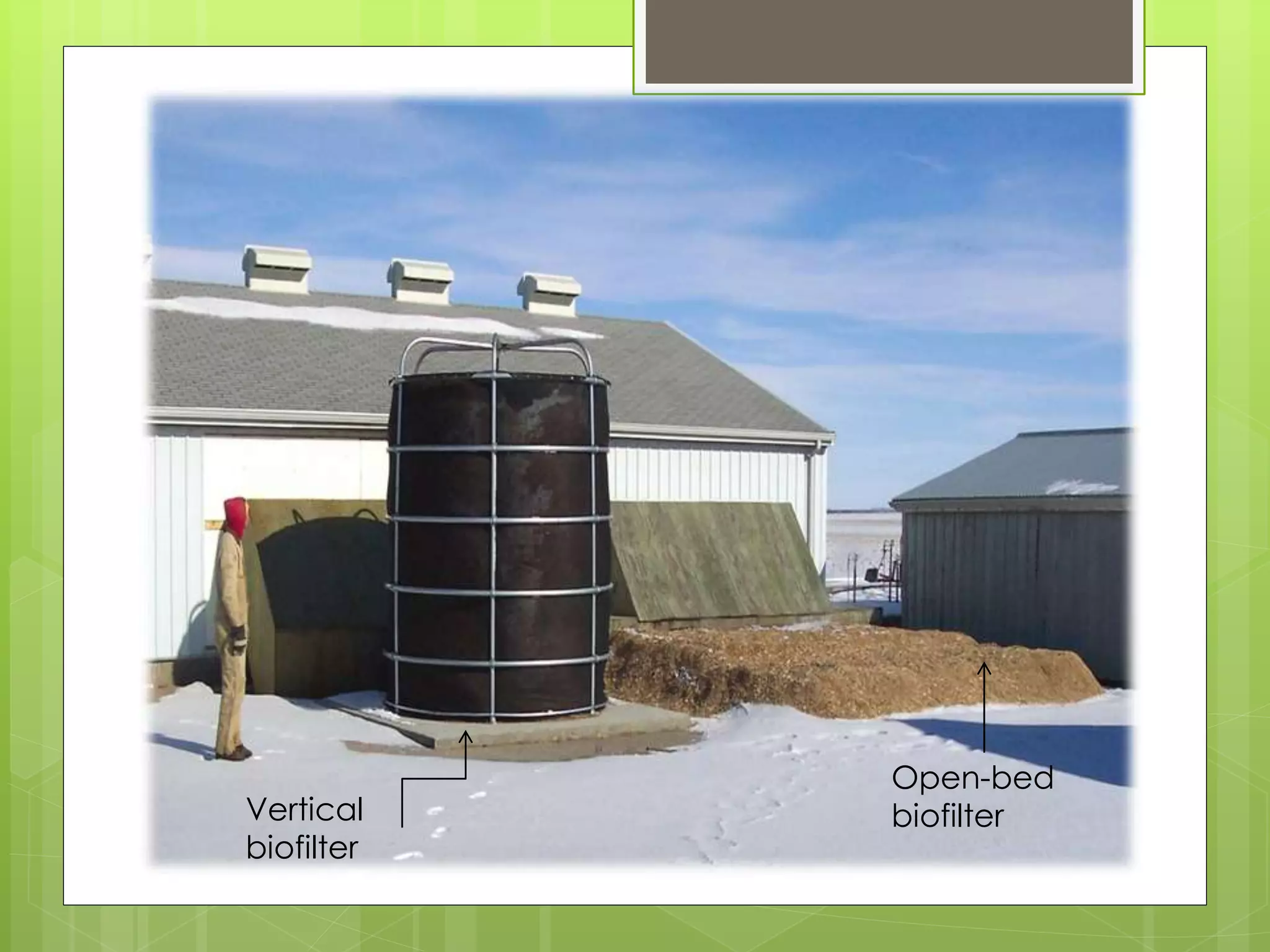

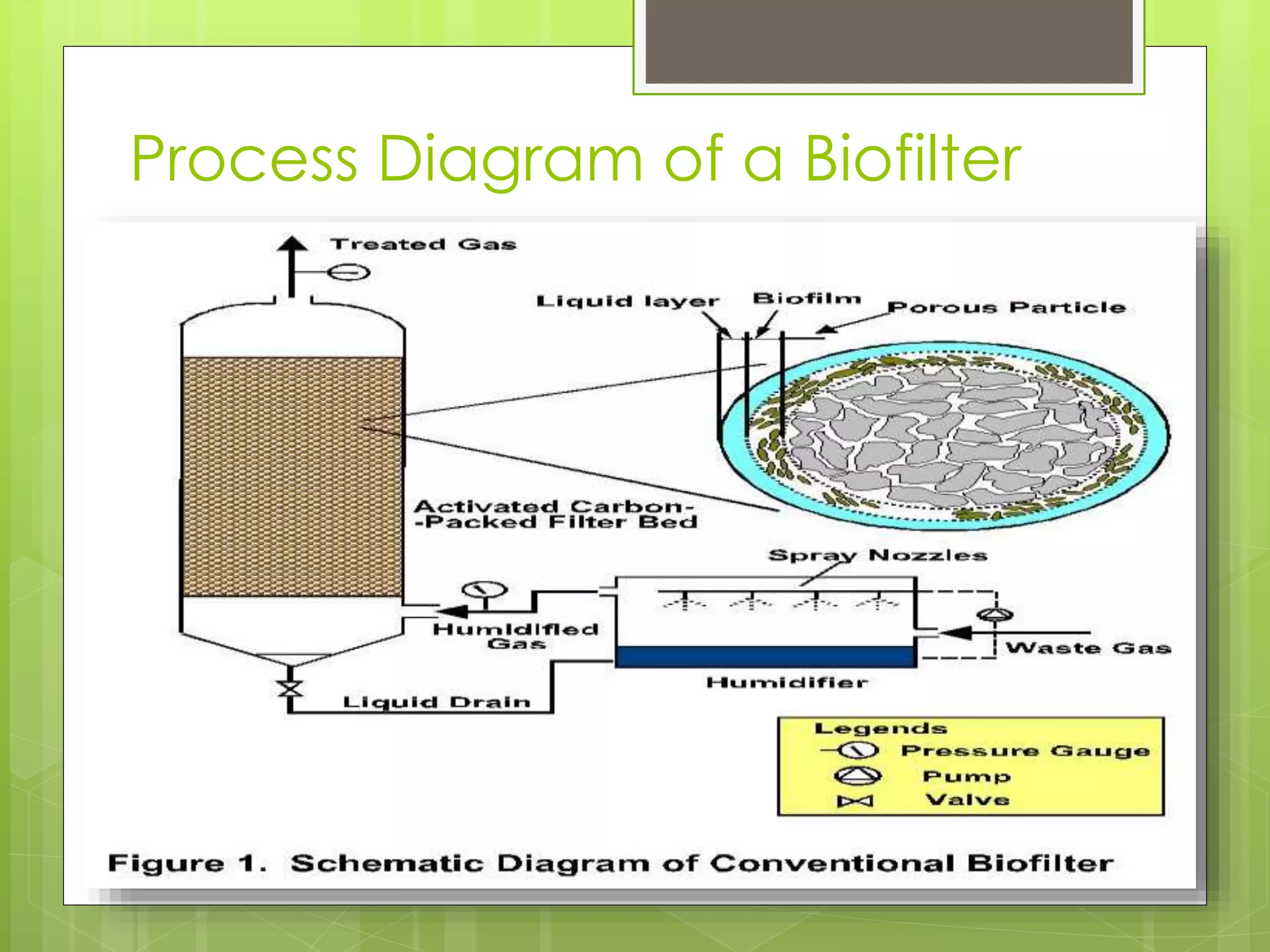

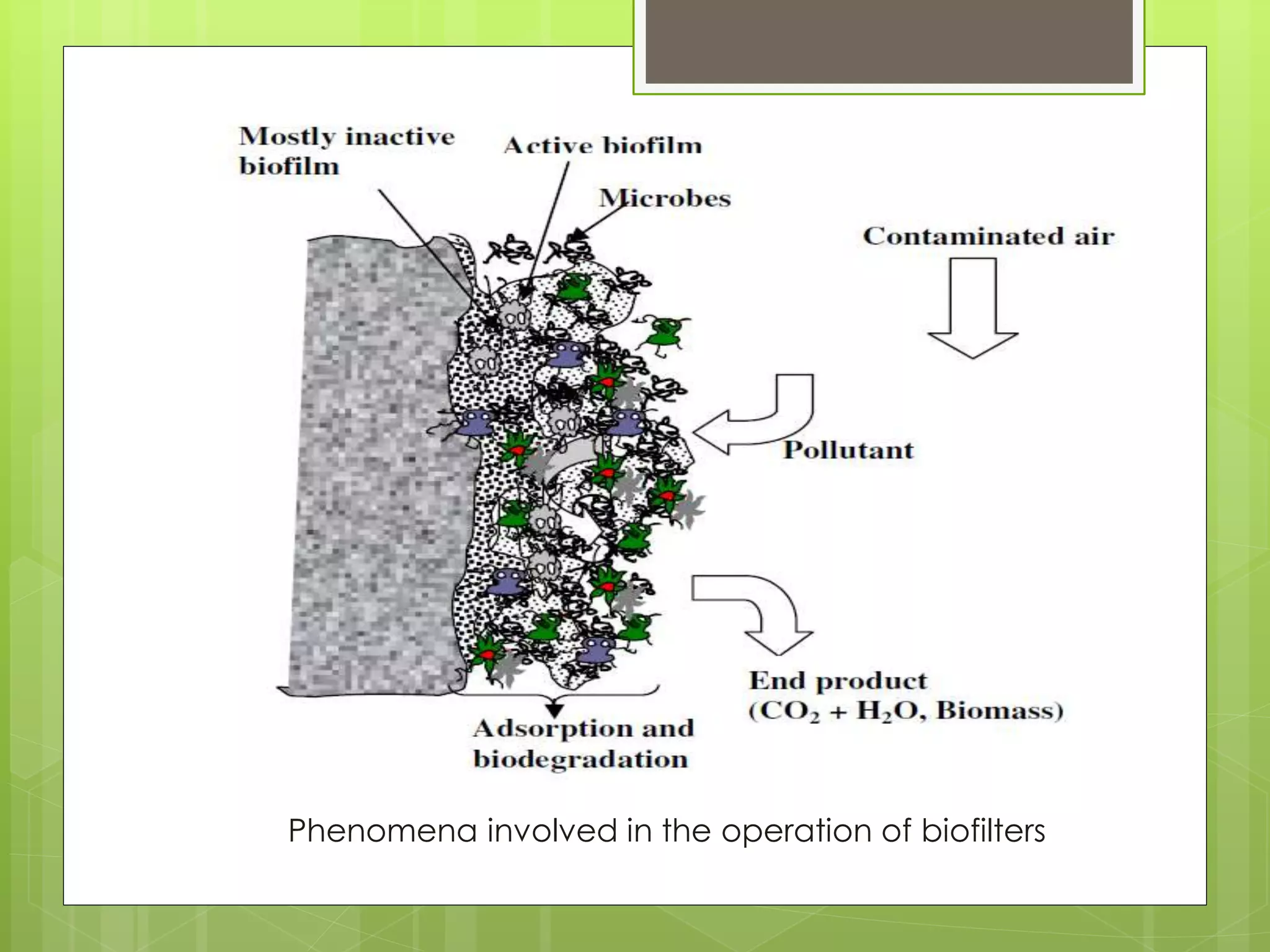

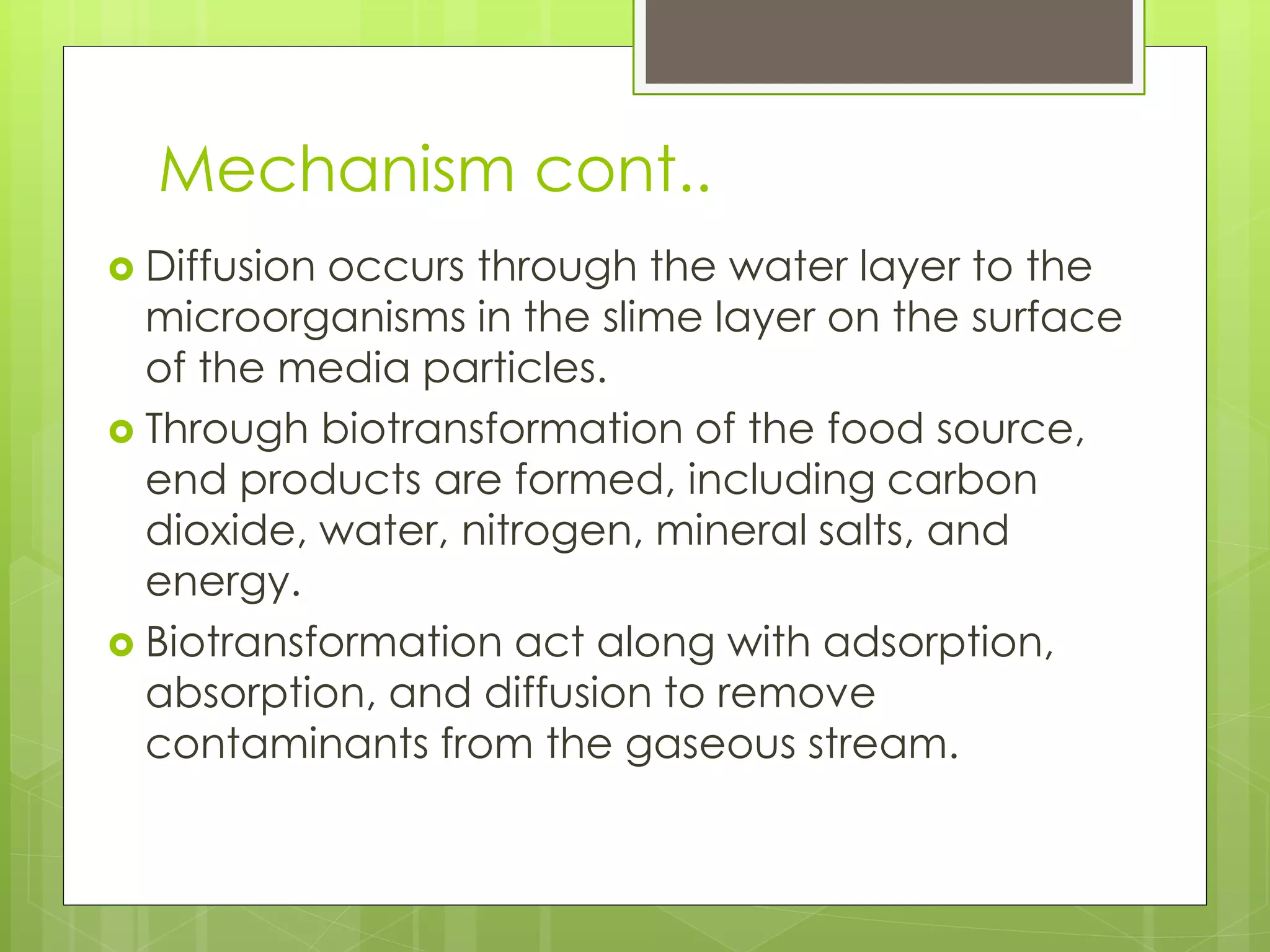

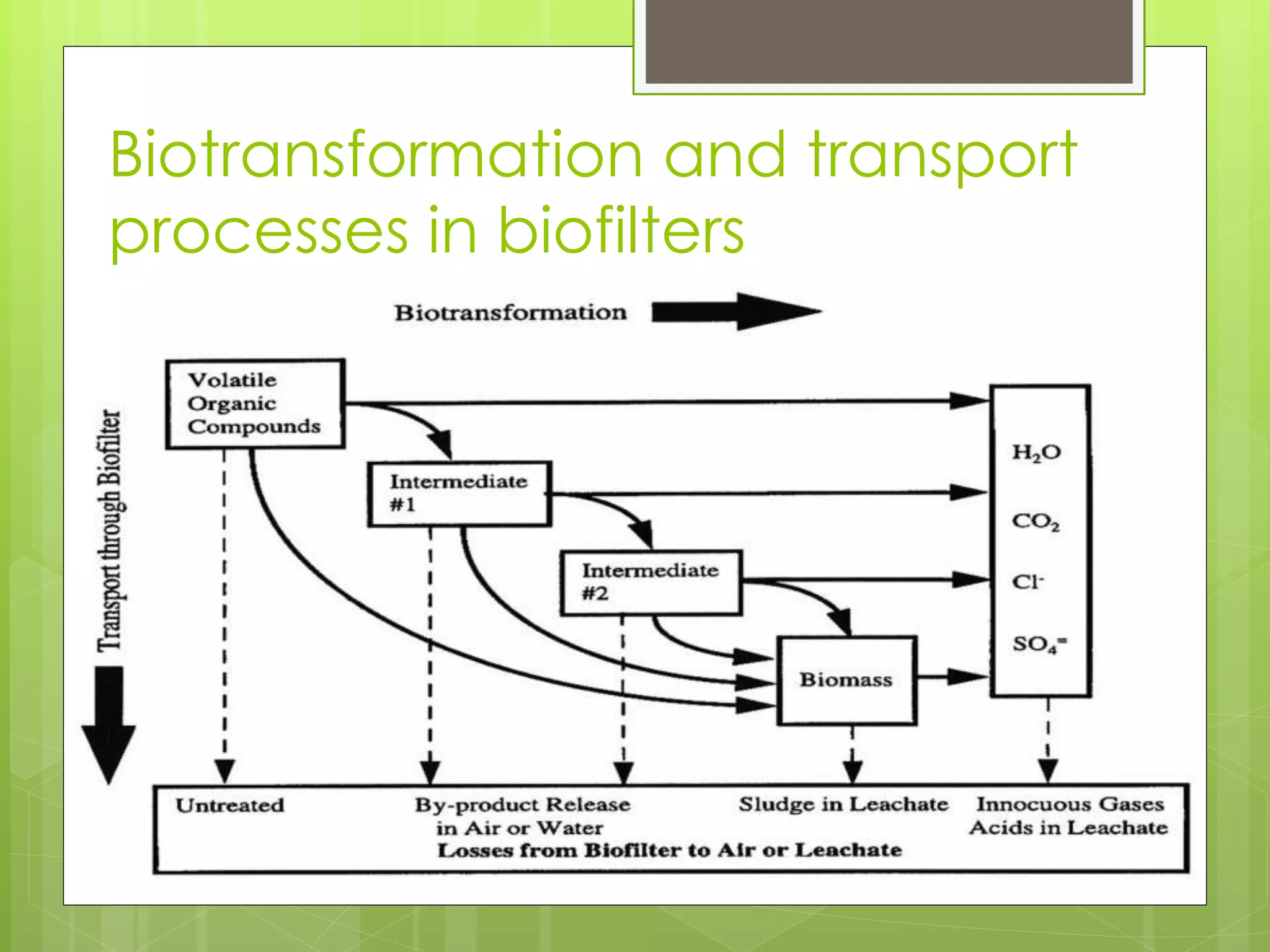

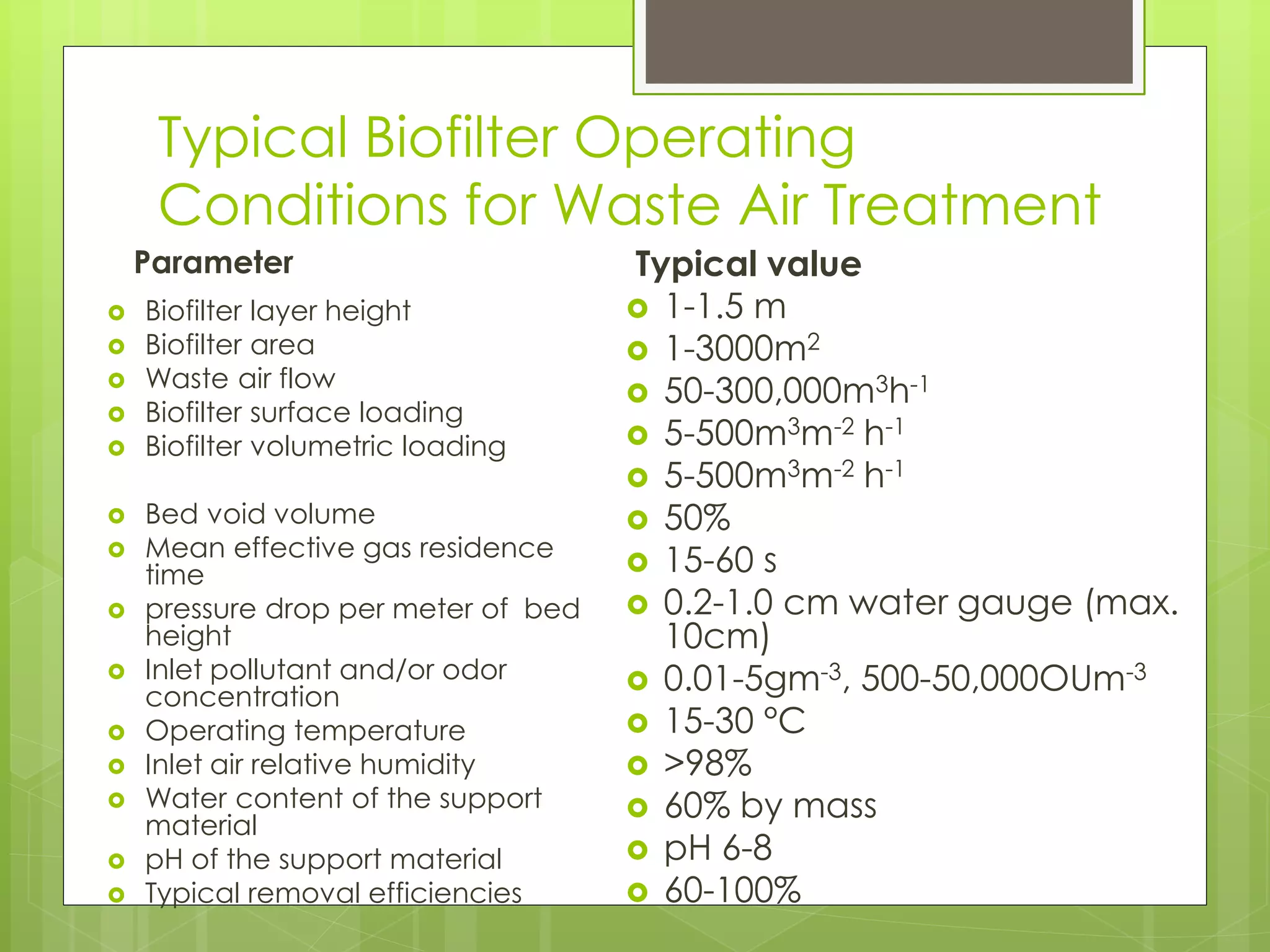

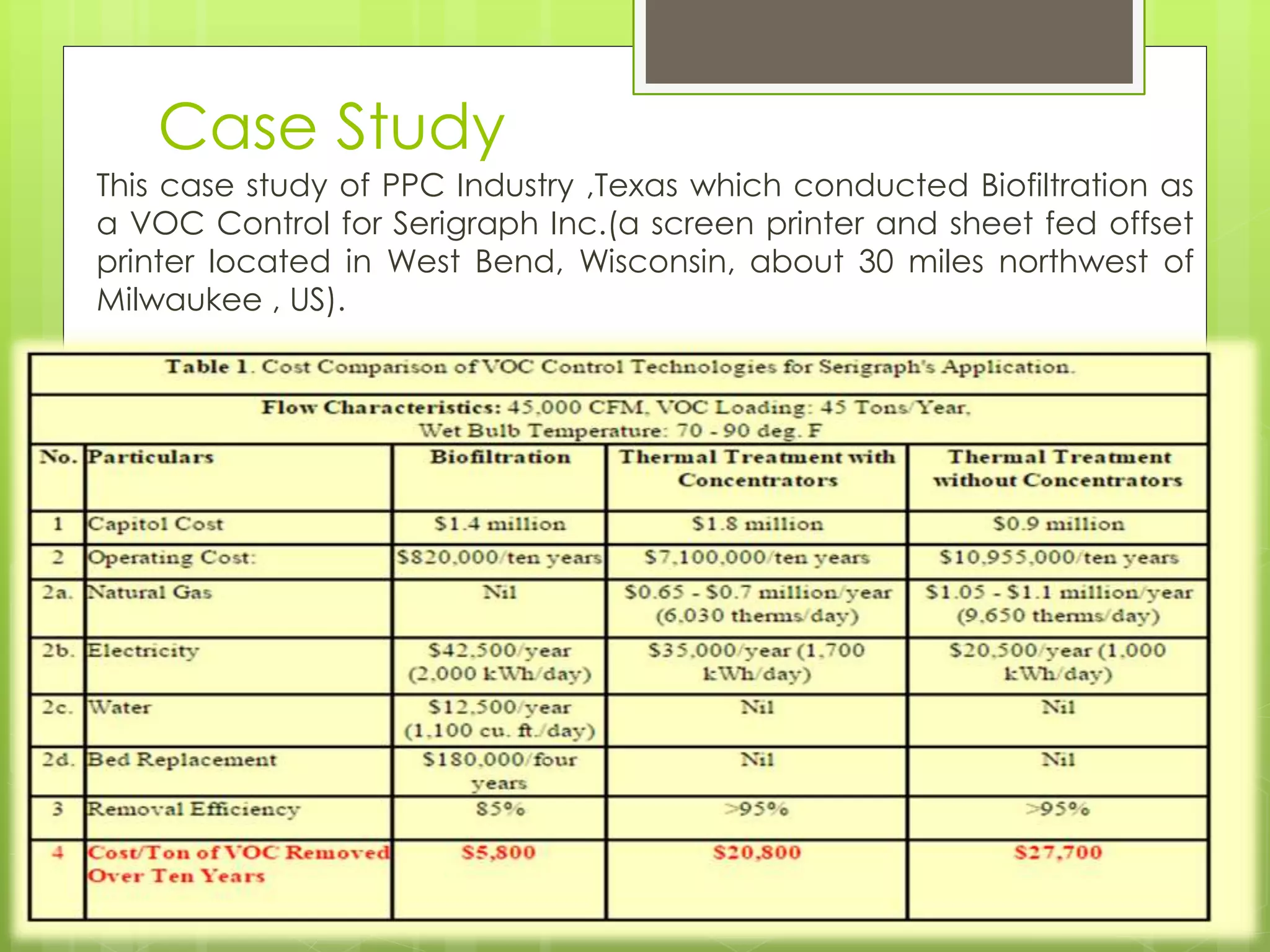

Biofiltration is an air pollution control technique that uses microorganisms to degrade contaminants in a moist environment, effectively targeting malodorous gases and volatile organic compounds. The document outlines the history, components, types, and operational mechanisms of biofilters, emphasizing the need for optimal conditions such as moisture, temperature, and nutrient supply for microbial effectiveness. Case studies highlight successful applications of biofilters in various industries, demonstrating their significance in controlling air pollution.