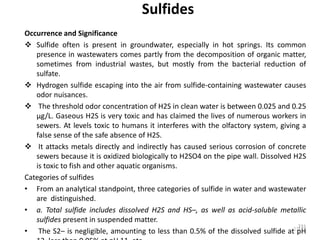

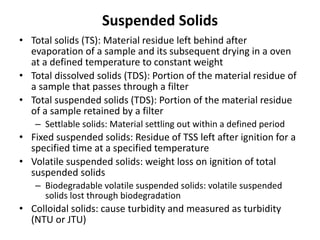

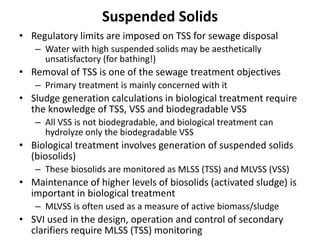

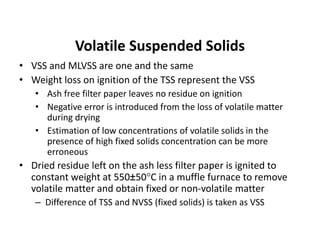

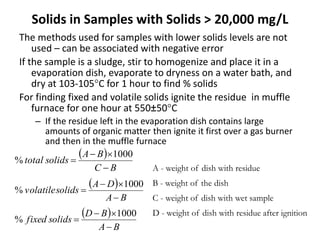

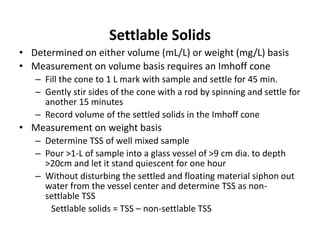

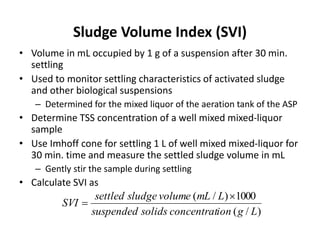

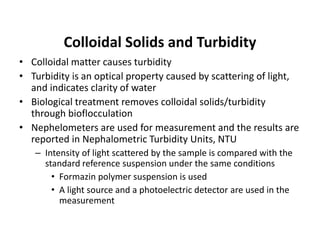

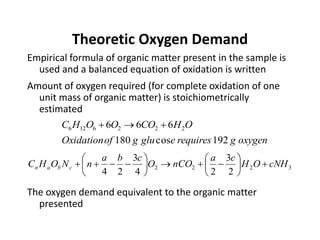

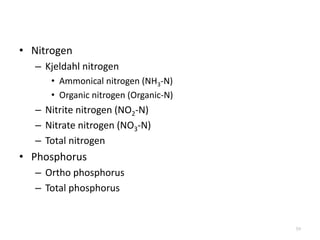

This document defines and describes various types of suspended solids and organic matter that are measured in wastewater treatment. It discusses total suspended solids (TSS), volatile suspended solids (VSS), biodegradable VSS, settleable solids, fixed suspended solids, and colloidal solids. It also covers measurements of organic matter including total organic carbon (TOC), theoretical oxygen demand (ThOD), chemical oxygen demand (COD), biochemical oxygen demand (BOD), and BOD kinetics. The document provides details on procedures for measuring these parameters, including the use of filters, ignition, centrifugation, Imhoff cones, and demand tests.

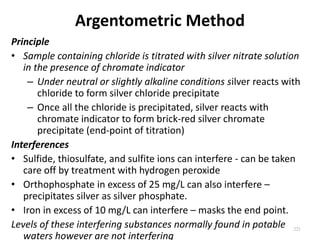

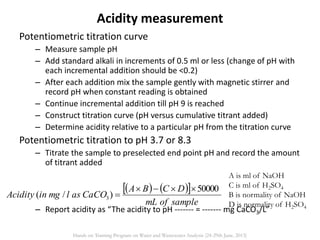

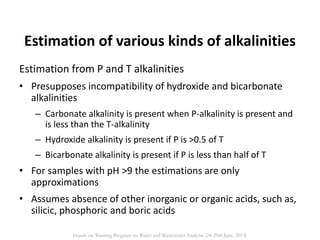

![Carbon dioxide estimation

Nomographic chart can be used

– Requires pH, alkalinity, dissolved solids and temperature of the sample

for the measurement

Can also be measured from the following expression

– If pH is not accurately measured CO2 measurement will be erroneous

(25% error in CO2 measurement for 0.1 unit error in pH measurement)

1

32

3

AK

COH

HCOH

Here [H2CO3] is sum of carbonic acid and free

Carbon dioxide (99% is free CO2)

Hands on Training Program on Water and Wastewater Analysis (24-29th June, 2013)](https://image.slidesharecdn.com/phacidityandalkanity-201014122543/85/PH-acidity-and-alkanity-203-320.jpg)

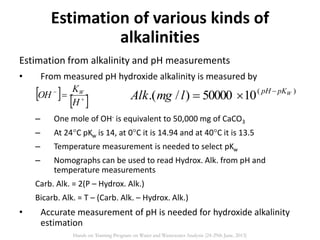

![Estimation from equilibrium

equations

Measurement of pH, total alkalinity, TDS and

temperature are needed

Sum of equivalent concentrations of cations

must be equal to the sum of

equivalent concentrations of anions

From pH and temperature measurements

[H+] and [OH-] can be estimated

Carb. Alk. and Bicarb. Alk. Can be measured

by

At 20C KA2 is 4.7X10-11

Temp. and ionic concentrations influence

the value of KA2

Nomographs can be used to know KA2 from

temp and TDS measurements

Estimation of various kinds of alkalinities

OHCOHCO

Alk

H 2

32

50000

.

WKHOH

H

K

H

K

H

T

AlkCarb

A

W

22

1

50000

50000

..

22

1

50000

50000

..

A

W

K

H

H

K

H

T

AlkBicarb

2

3

2

3

AK

HCO

COH

Hands on Training Program on Water and Wastewater Analysis (24-29th June, 2013)](https://image.slidesharecdn.com/phacidityandalkanity-201014122543/85/PH-acidity-and-alkanity-214-320.jpg)