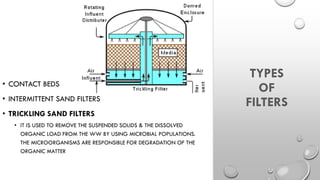

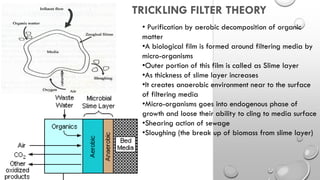

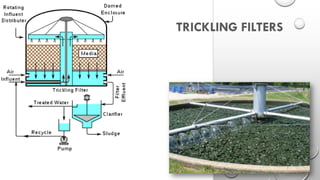

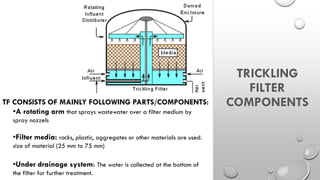

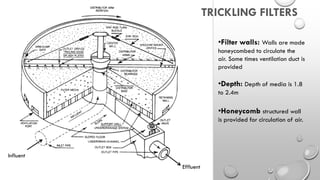

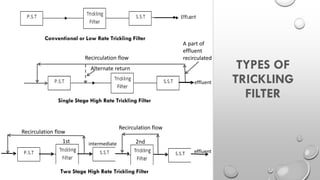

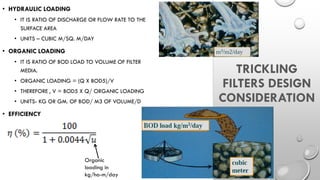

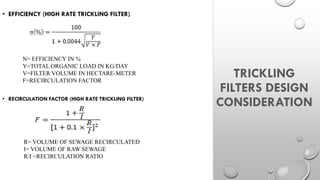

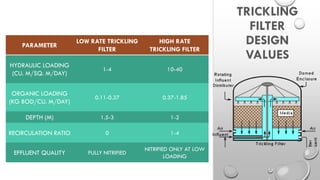

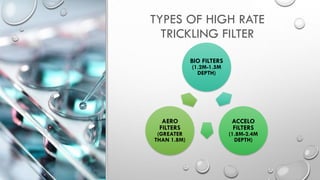

The document discusses trickling filters, which are used in sewage treatment to remove suspended solids and dissolved organic loads from wastewater. Trickling filters use microbial populations attached to a filter media to break down organic matter. They consist of a rotating arm that sprays wastewater over a rock or plastic media, with wastewater collected below for further treatment. Trickling filters can be designed as low or high rate systems, with high rate filters having greater organic loading, hydraulic loading, and recirculation ratios compared to low rate filters. Operational issues include ponding, odors, and fly nuisance that can occur if the filters become anaerobic or clogged.