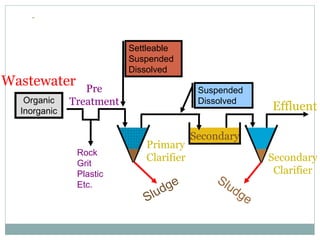

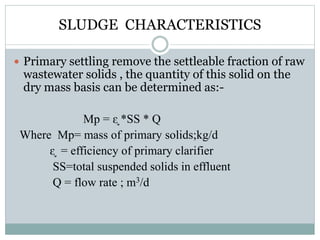

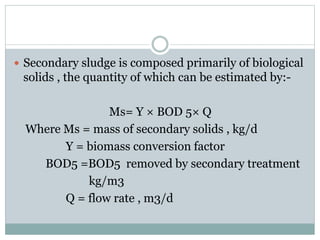

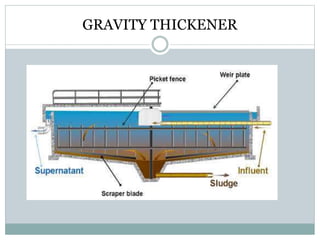

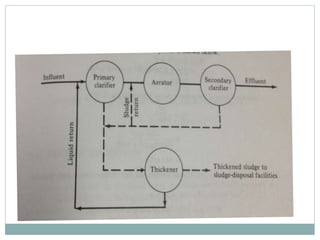

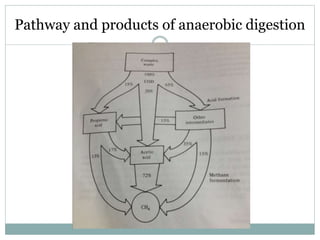

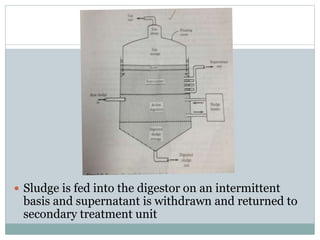

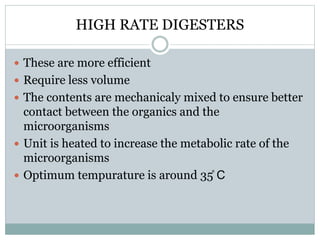

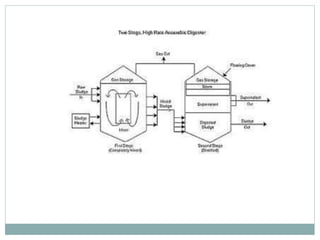

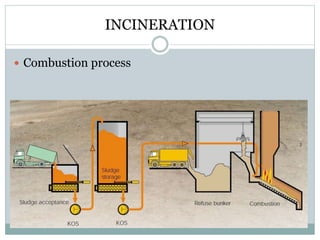

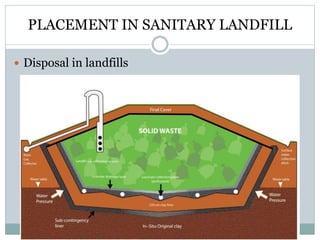

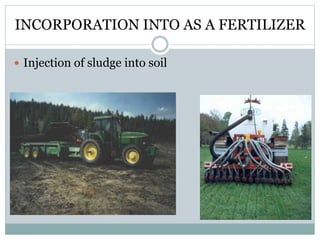

The document discusses sludge treatment and disposal methods in wastewater treatment. It describes how sludge is produced from primary and secondary treatment and its characteristics. Key steps in sludge treatment include thickening to increase solid concentration, digestion to reduce volume and pathogens, and final disposal through incineration, landfilling, or use as fertilizer. Anaerobic digestion is most common and converts sludge into gases and residual biomass through acid-forming and methane-forming bacteria. Aerobic digestion is an alternative but is more energy intensive.