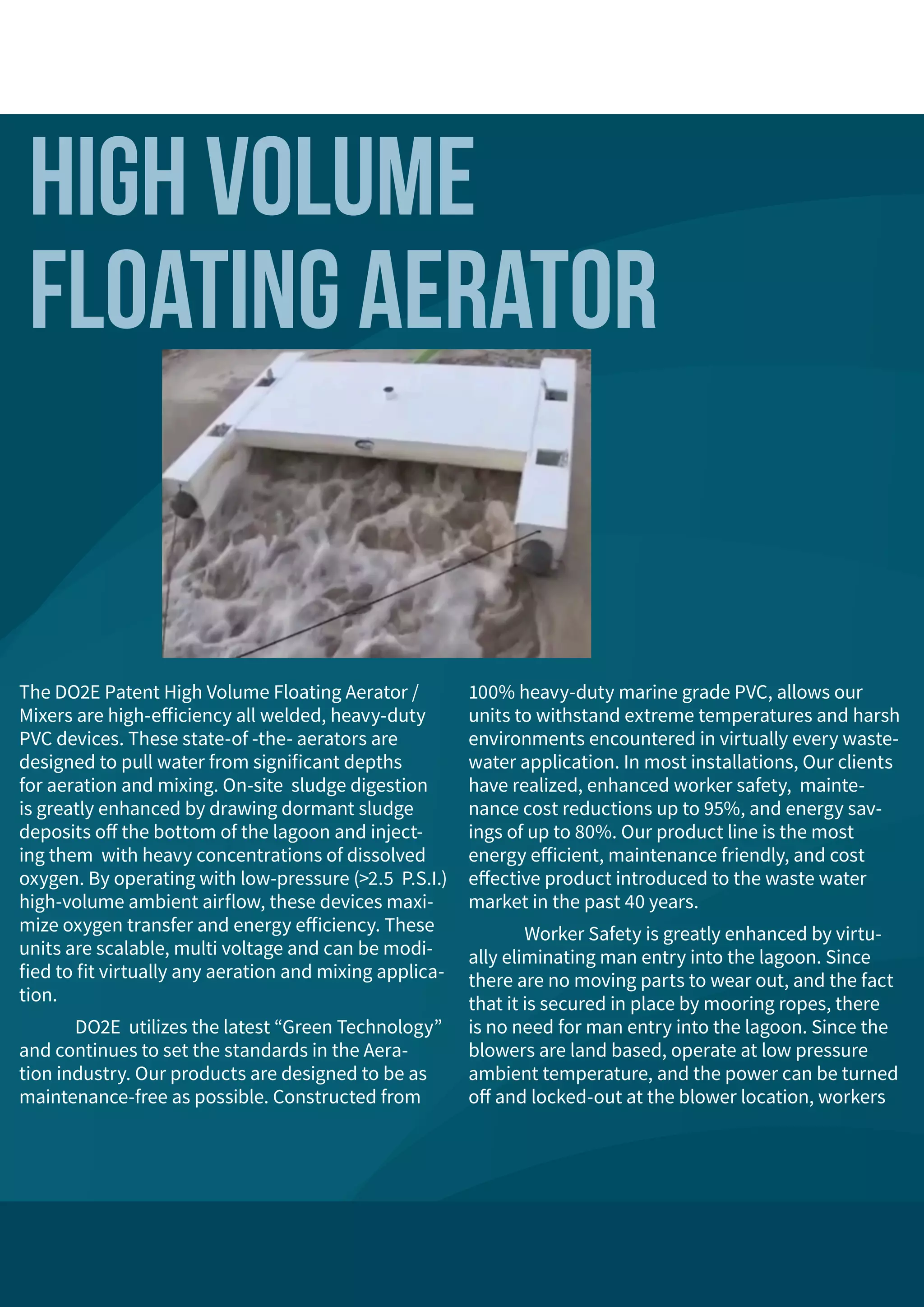

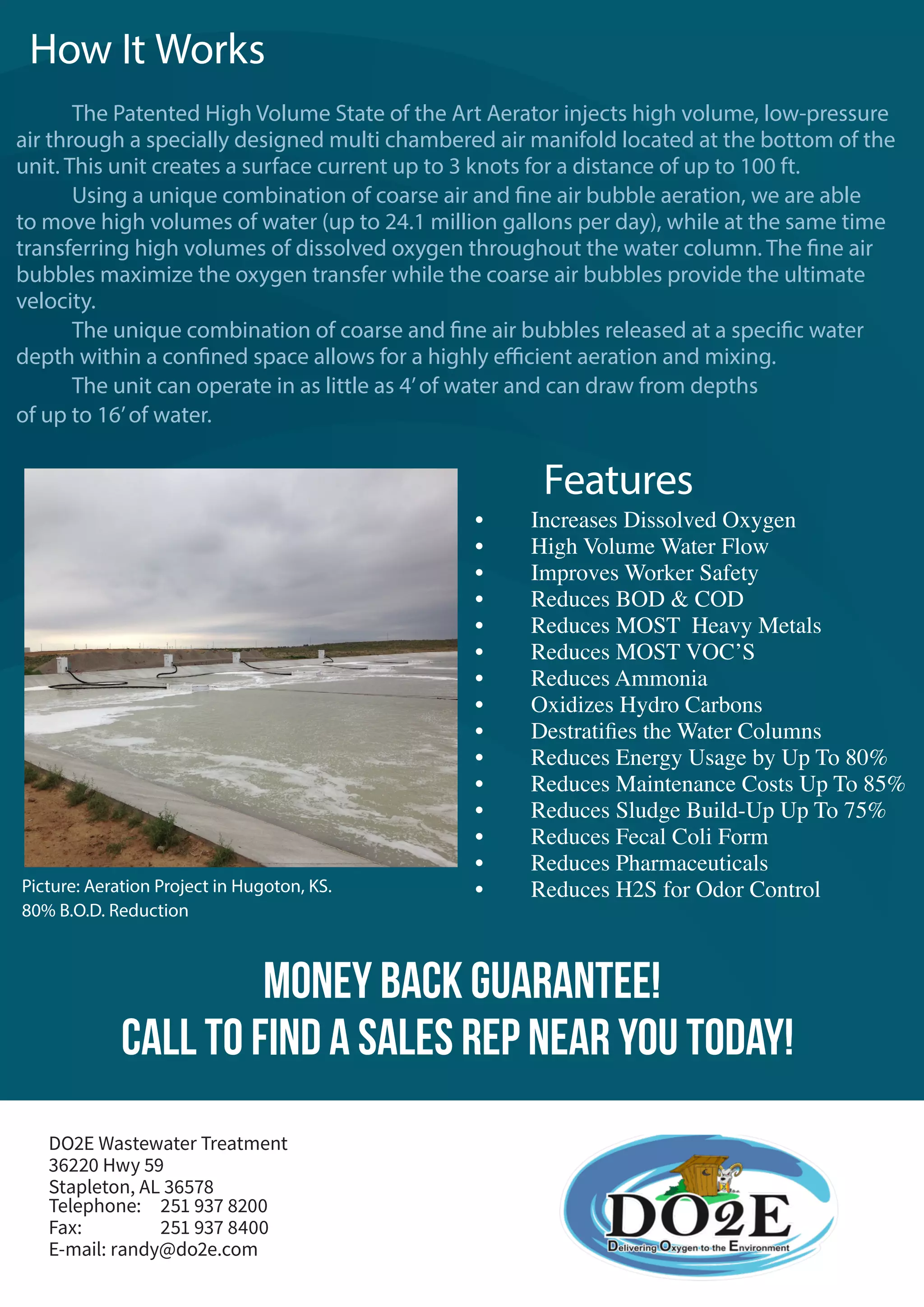

This document describes a high volume floating aerator and mixer produced by DO2E Wastewater Treatment. The aerator is designed to enhance on-site sludge digestion by drawing dormant sludge deposits into the water column and injecting them with dissolved oxygen. It operates using low-pressure, high-volume airflow to maximize oxygen transfer and energy efficiency while aerating and mixing large volumes of water. The aerator is constructed from durable PVC materials and designed for maintenance-free operation, enhanced worker safety, and reduced energy and maintenance costs compared to other aeration equipment.