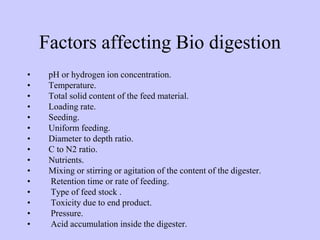

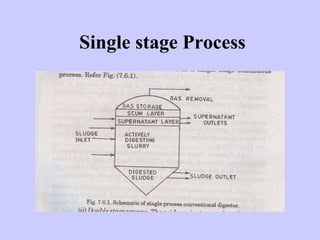

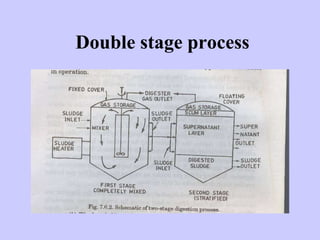

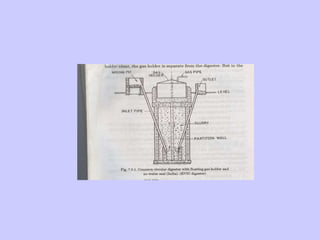

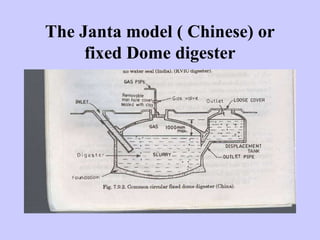

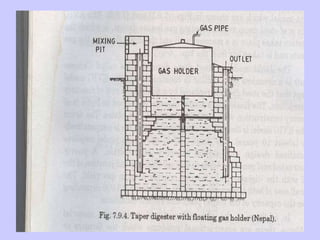

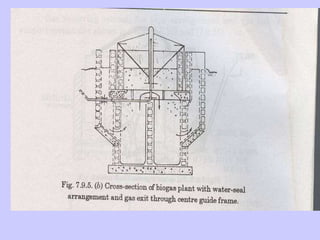

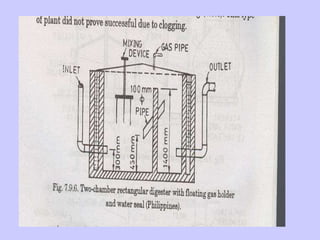

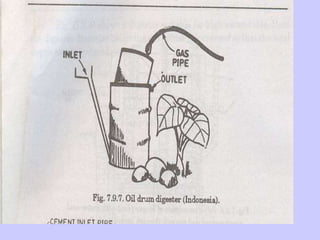

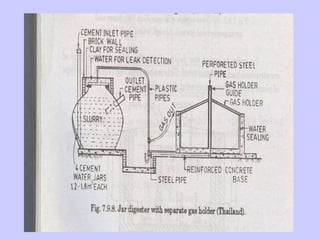

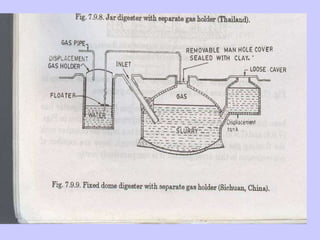

This document discusses biomass energy and biogas production. It describes photosynthesis, biomass fuels, and factors that affect biogas generation such as pH, temperature, loading rate, and retention time. It also discusses types of biogas plants and the advantages of anaerobic digestion which include producing a stable sludge and reducing pathogens. Biogas can be used to reduce coal consumption and air pollution. The document classifies biogas plants as either continuous or batch systems and describes common dome and drum reactor designs.