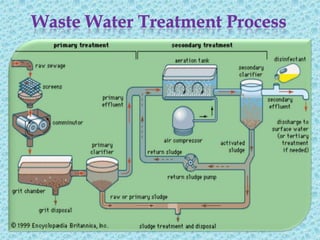

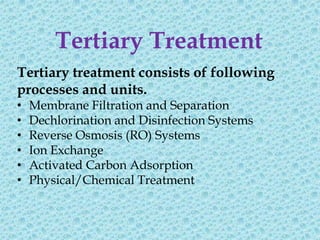

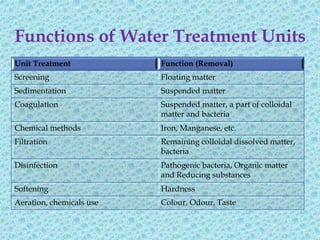

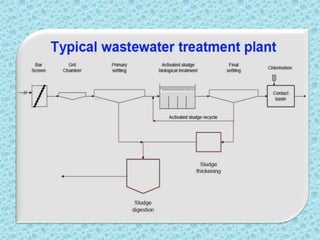

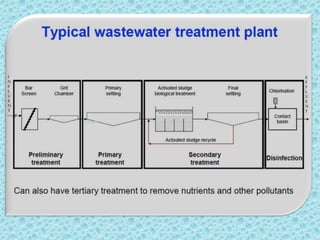

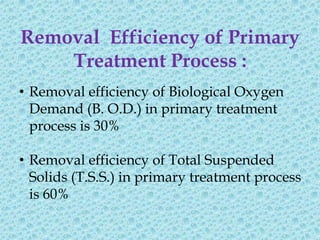

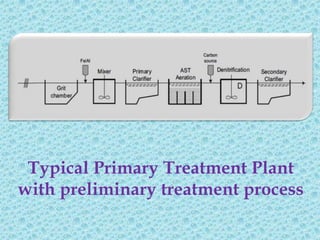

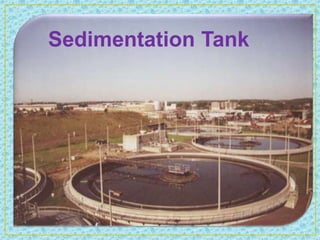

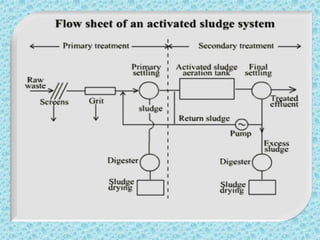

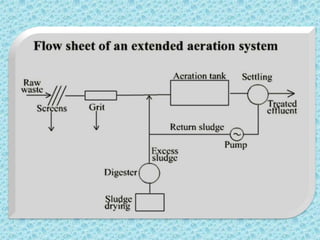

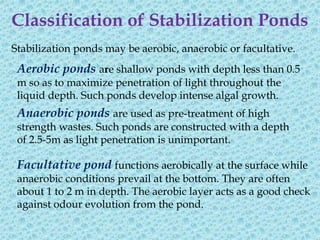

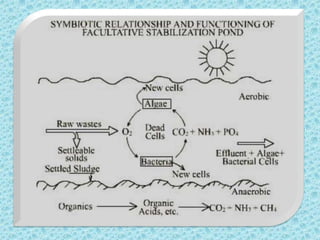

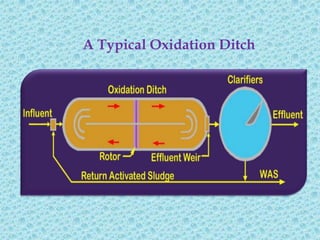

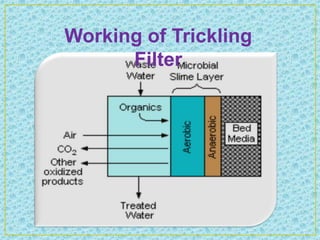

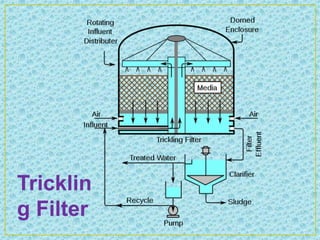

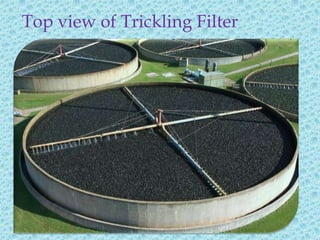

The document summarizes various stages of wastewater treatment processes. It discusses preliminary treatment which removes solids, grit, and grease. Primary treatment uses sedimentation to remove 60% of suspended solids. Secondary treatment uses biological processes like activated sludge and oxidation ditches to remove organic matter. Tertiary treatment further removes nutrients and particles through processes like filtration and disinfection. The document provides details on the treatment units and processes involved at each stage of wastewater treatment.