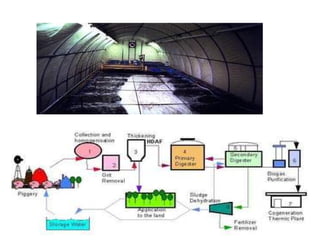

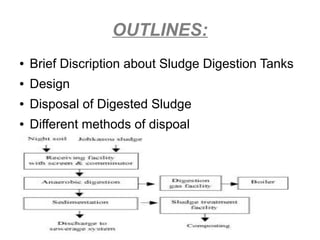

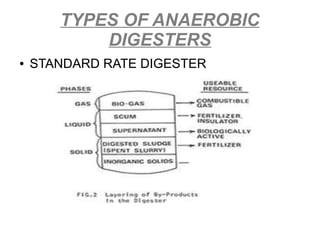

This presentation summarizes the process of sewage sludge digestion and disposal. It introduces sludge digestion tanks, which use anaerobic digestion to break down sewage sludge into biogas like methane. The presentation covers the design of standard and high rate sludge digestion tanks, and describes how the digested sludge can be disposed of through methods like disposal in water, burial on land, use as landfill, or composting. The goal is to stabilize the sludge and reduce its volume before safe disposal.

![DESIGN DETAILS:

● Generally digesters are designed to treat for a

capacity upto 4MLD.

● Tank sizes are not less thean 6m diameter and

not more than 55m diameter.

● Liquid depth may be be 4.5-6m and not greater

than 9m.

● v=[Vf-2/3(Vf-Vd)]t1+Vdt2

● v=capacity of digester in m3, Vf+volume of fresh sludge m3/d,

Vd=volume of daily digested sludge accumulation in tank m3/d,

t1=digestion time in days, dand t2 are period of digested sludge

storage.](https://image.slidesharecdn.com/pptmdu-200409194446/85/Ppt-mdu-9-320.jpg)