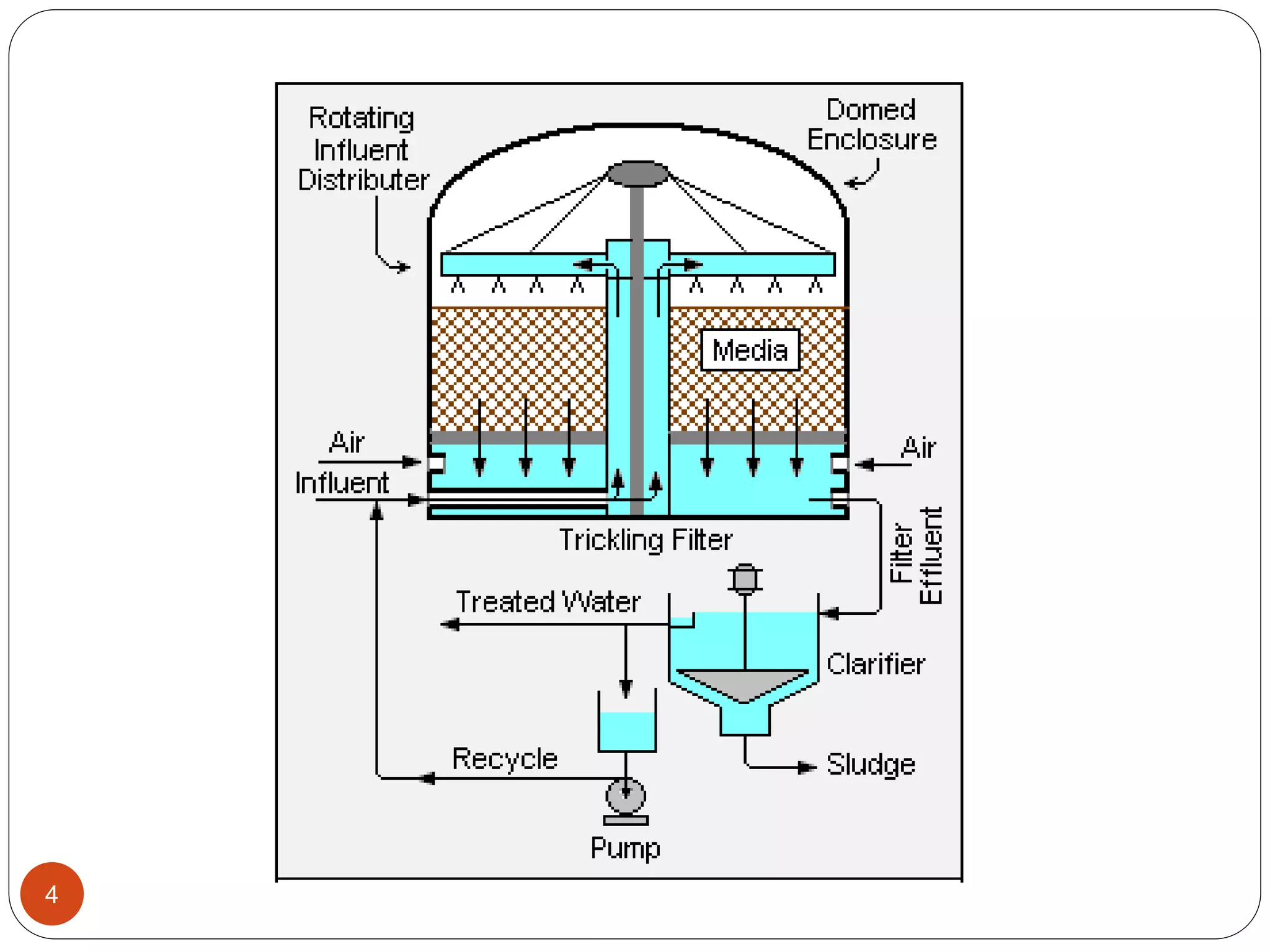

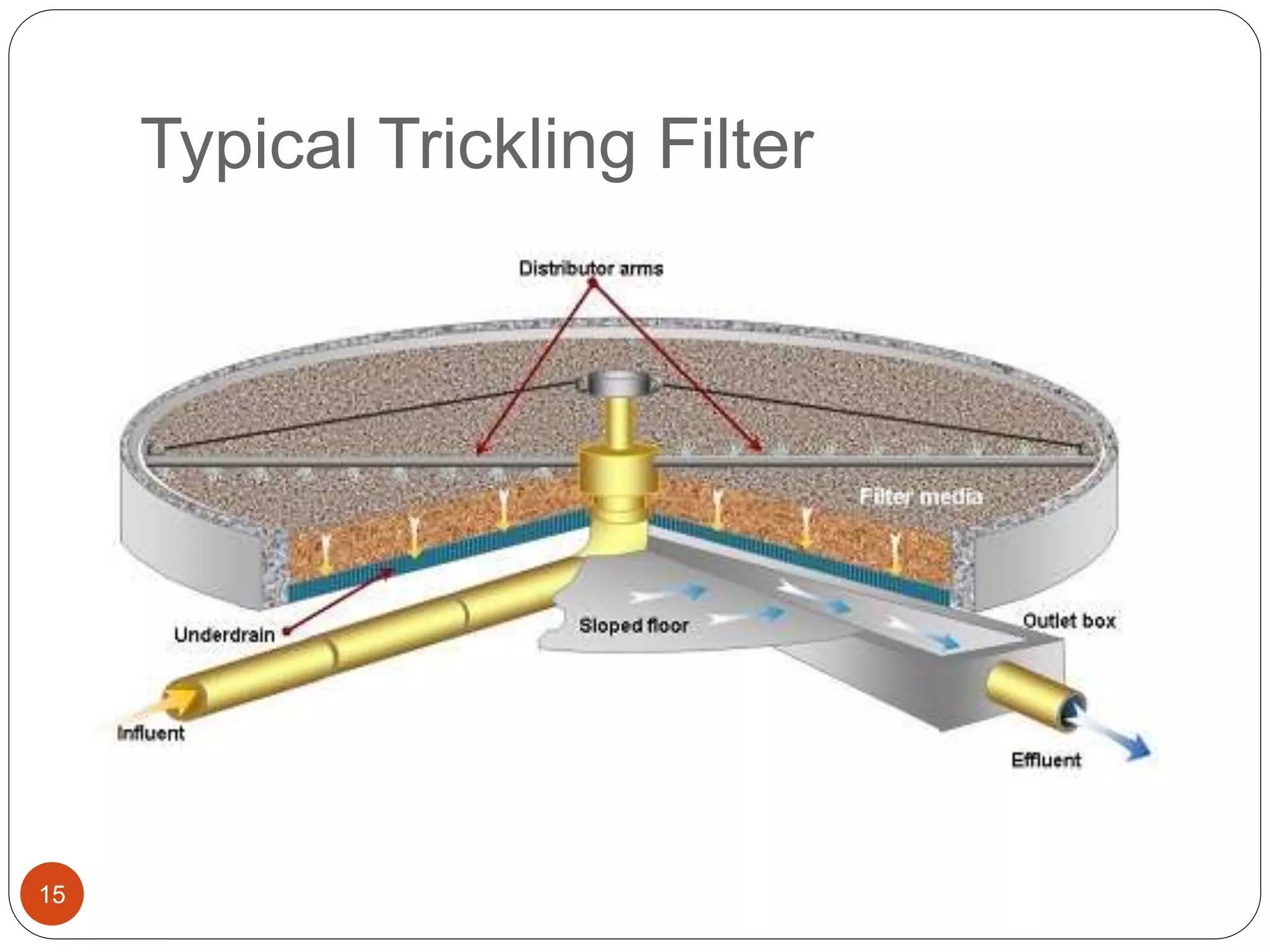

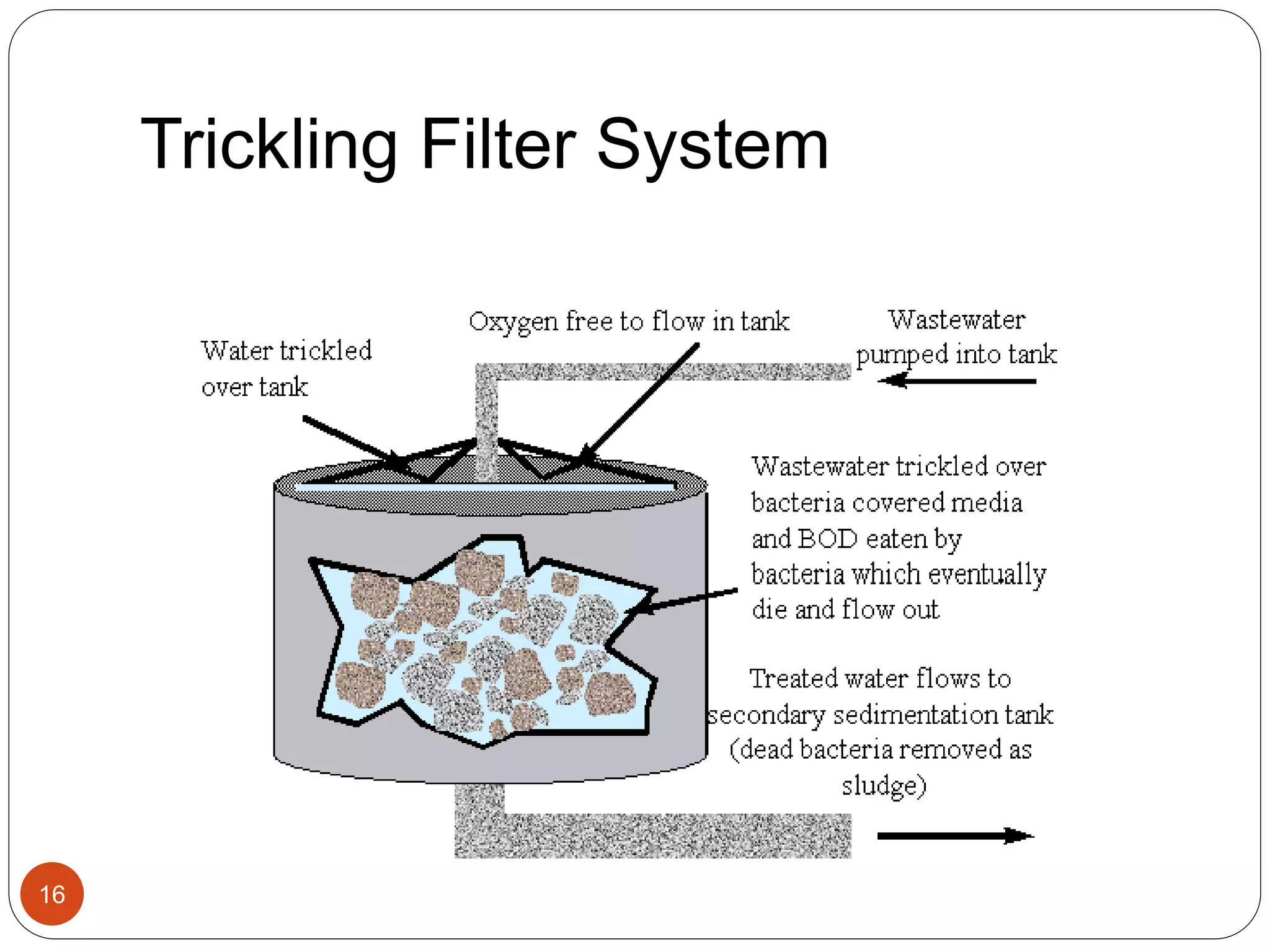

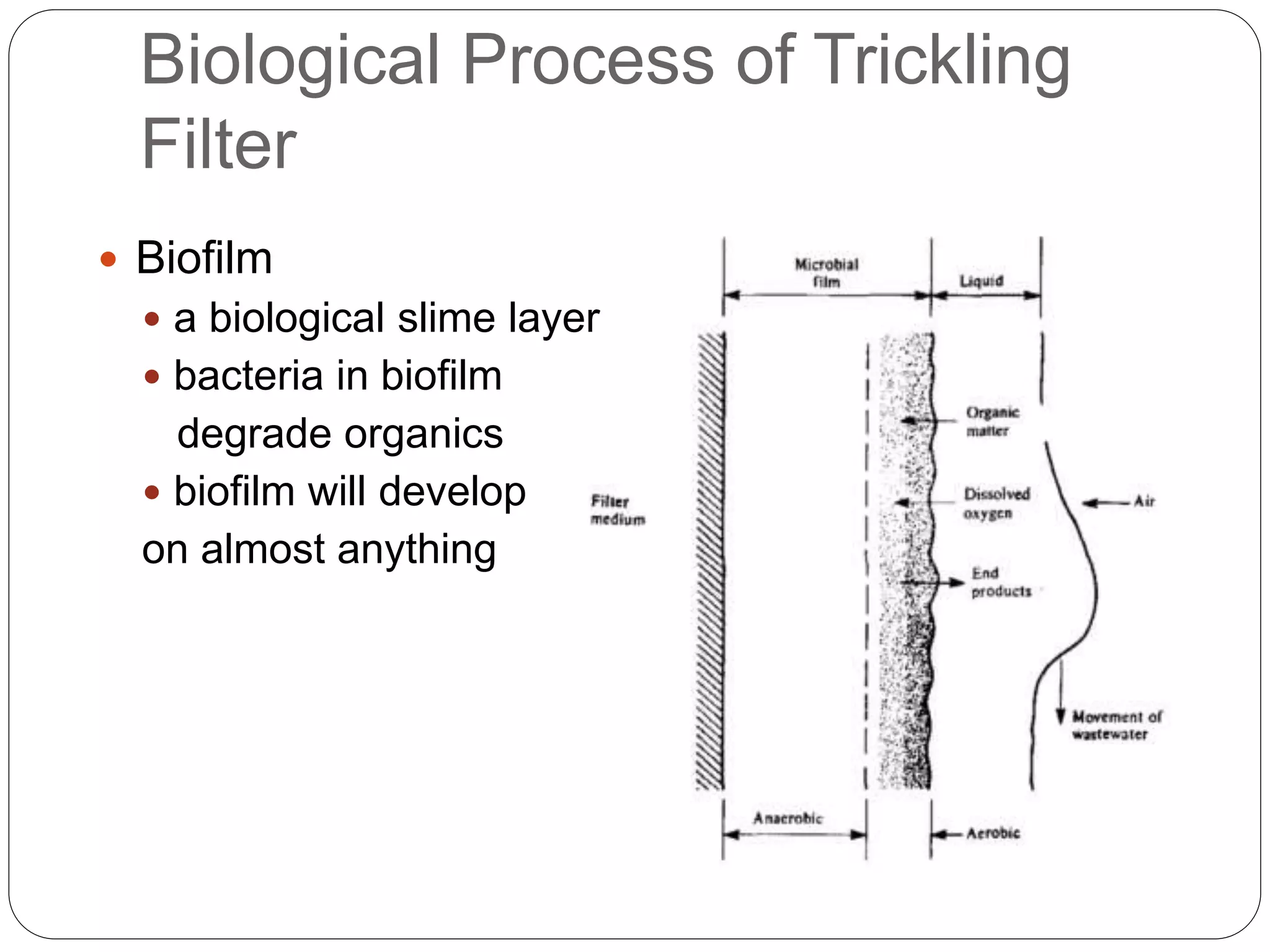

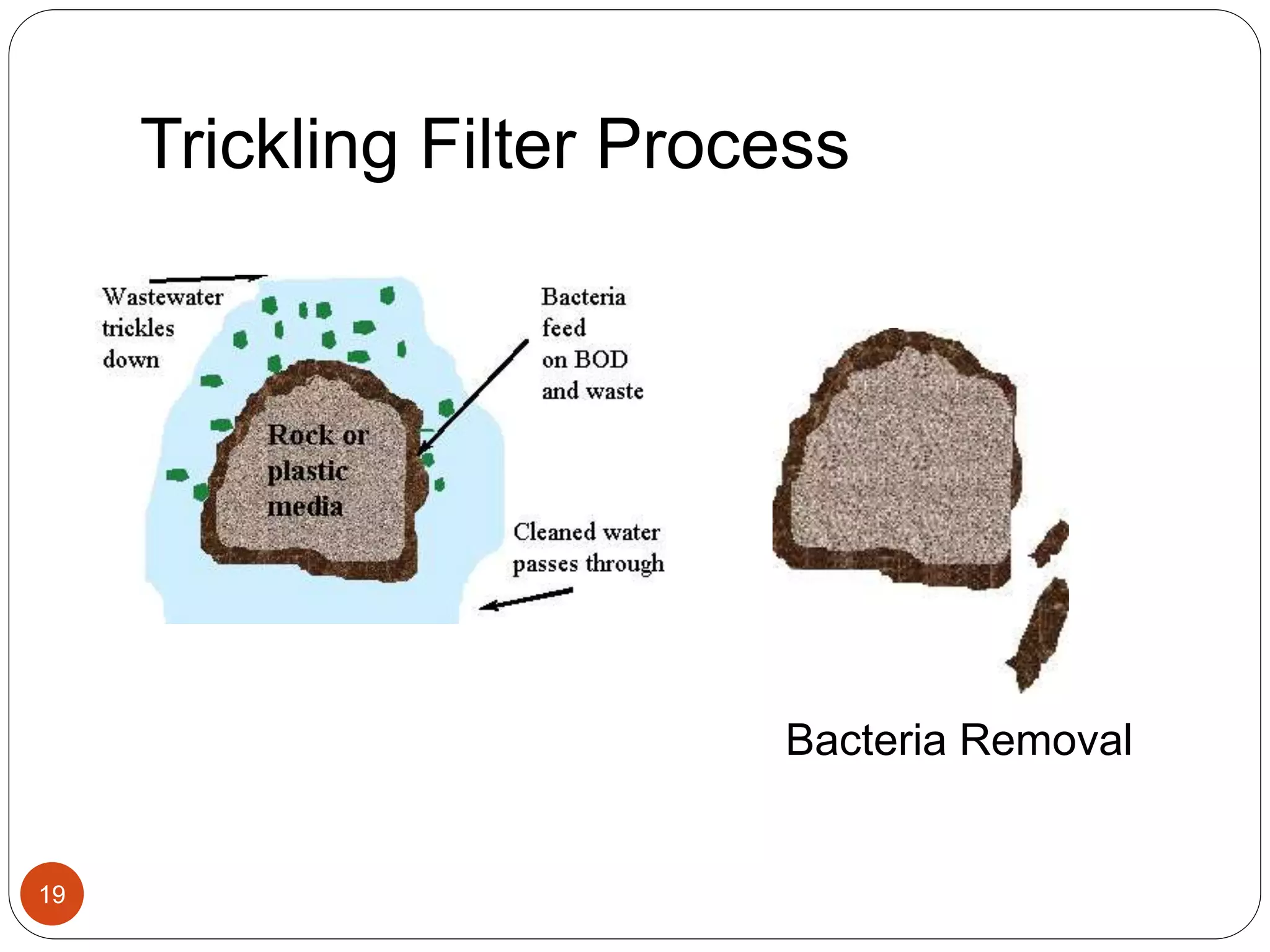

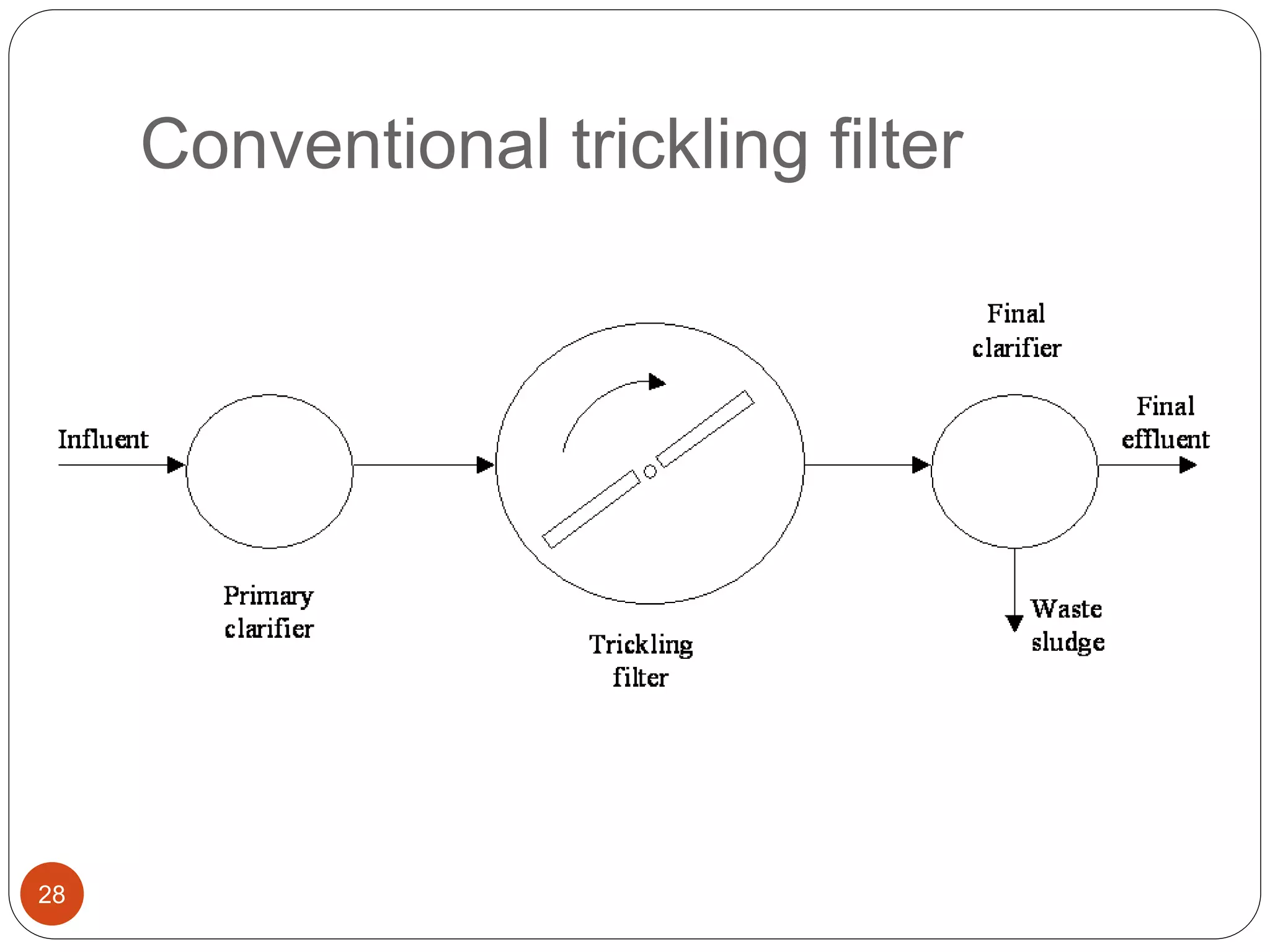

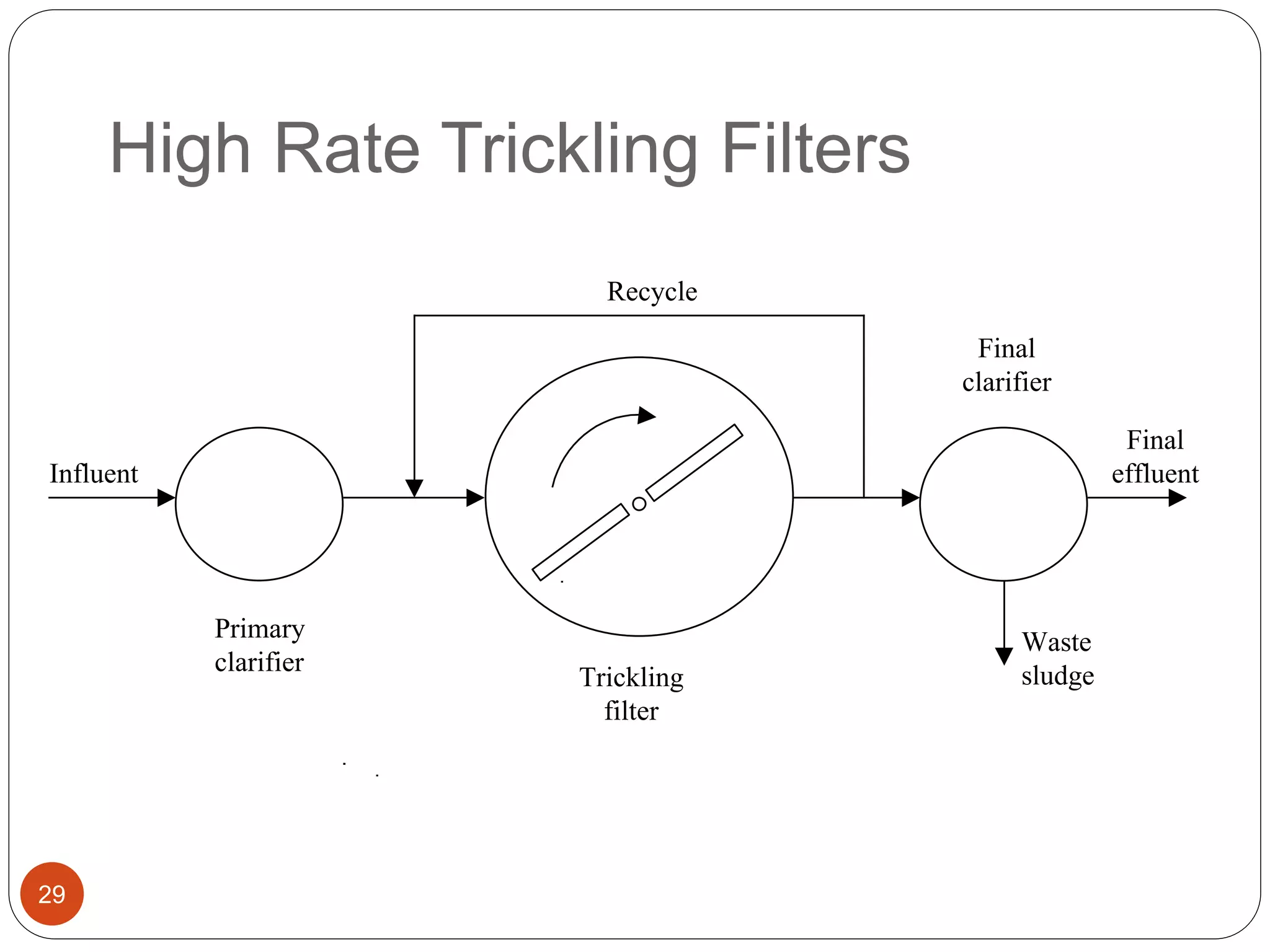

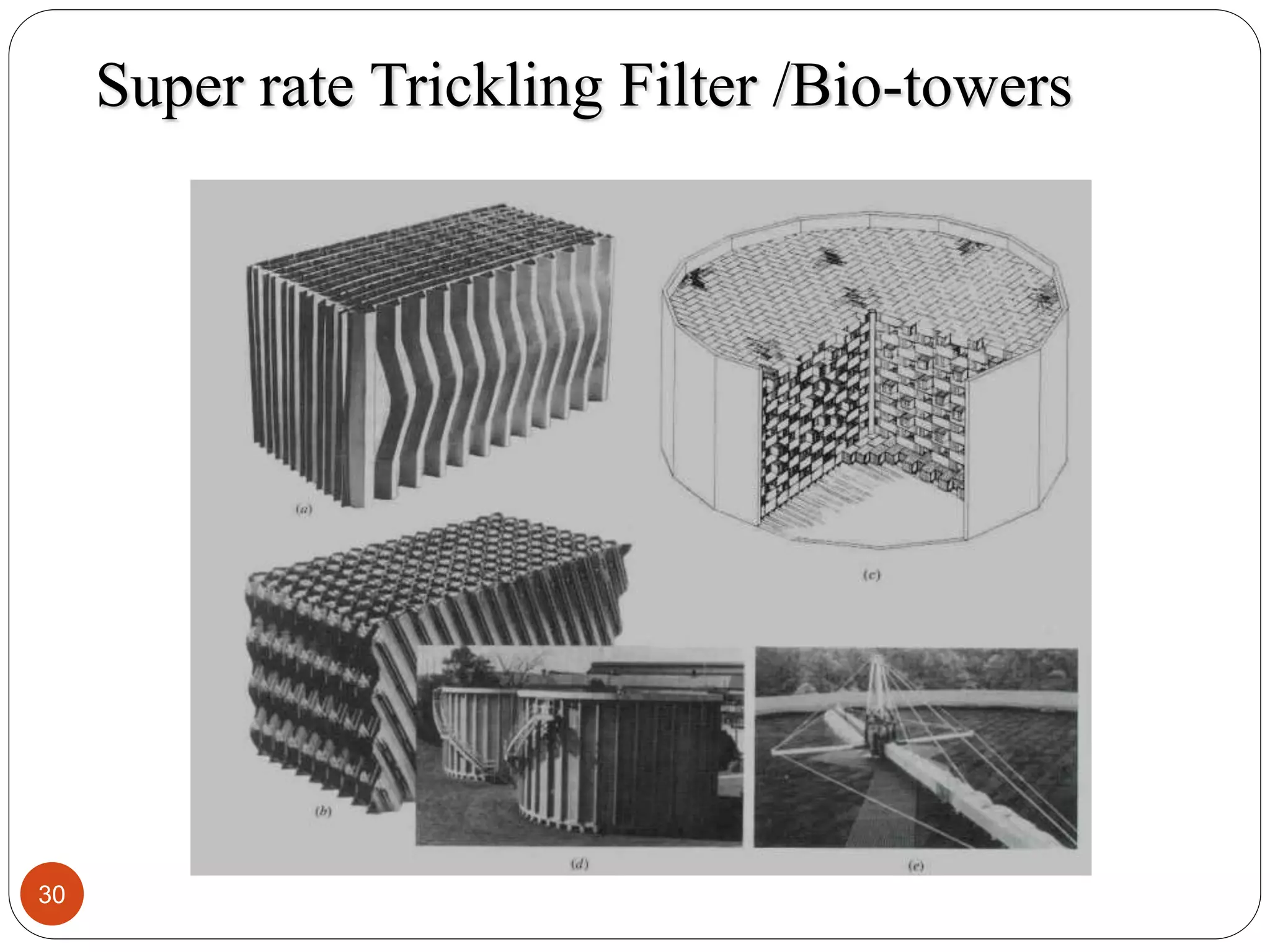

The document describes a trickling filter, which is a biological wastewater treatment process using attached growth of microorganisms on media to remove organic matter. Wastewater is distributed over the top of the media (such as gravel or plastic), where microbes grow as biofilms and degrade organics. The treated water exits through underdrains while air flow through the media supports the aerobic biofilms. Higher rate filters use recirculation and plastic media to achieve greater organic removal at smaller footprints. Proper design and operation are needed to control issues like ponding, flies, odors, and icing.