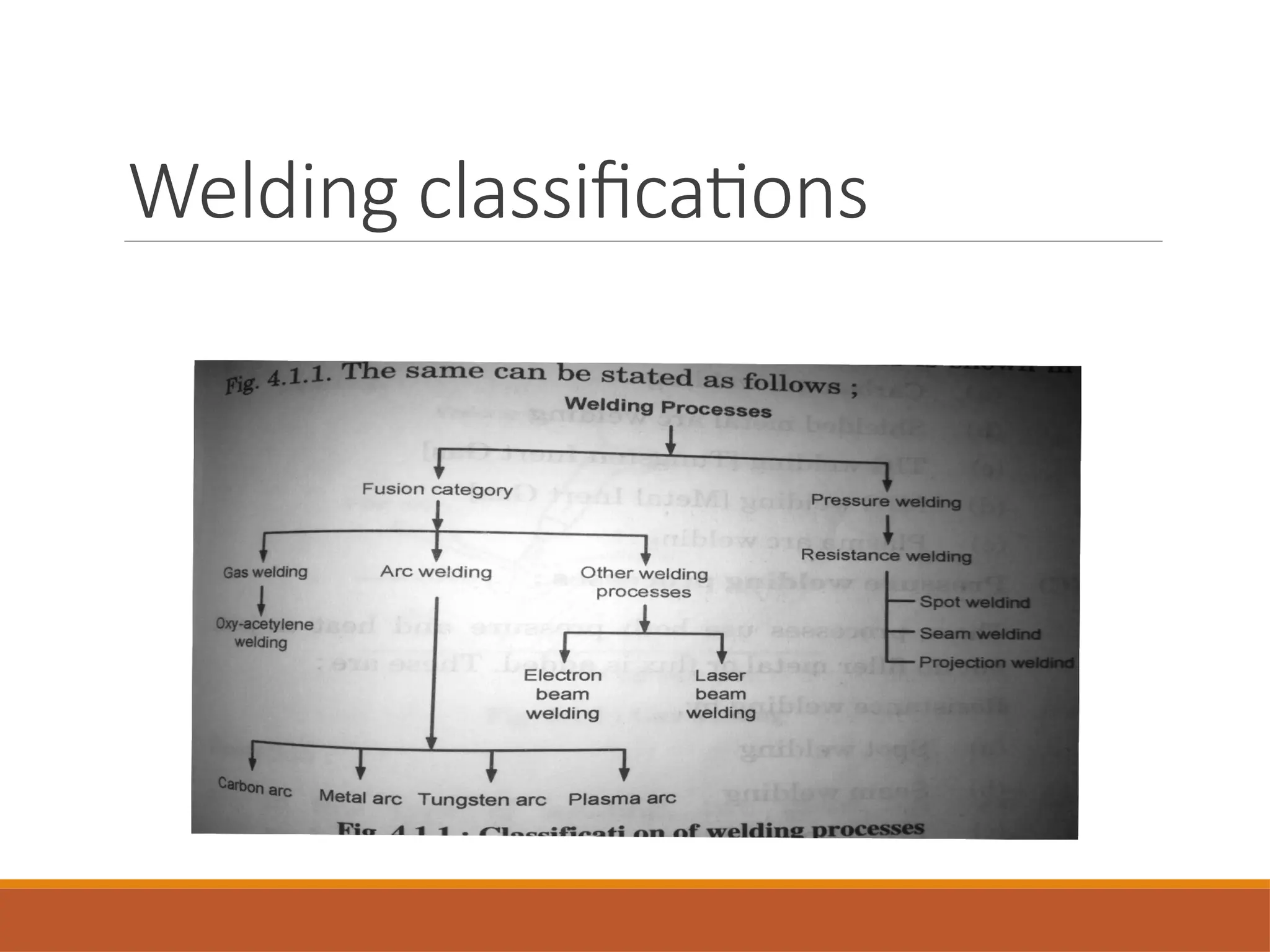

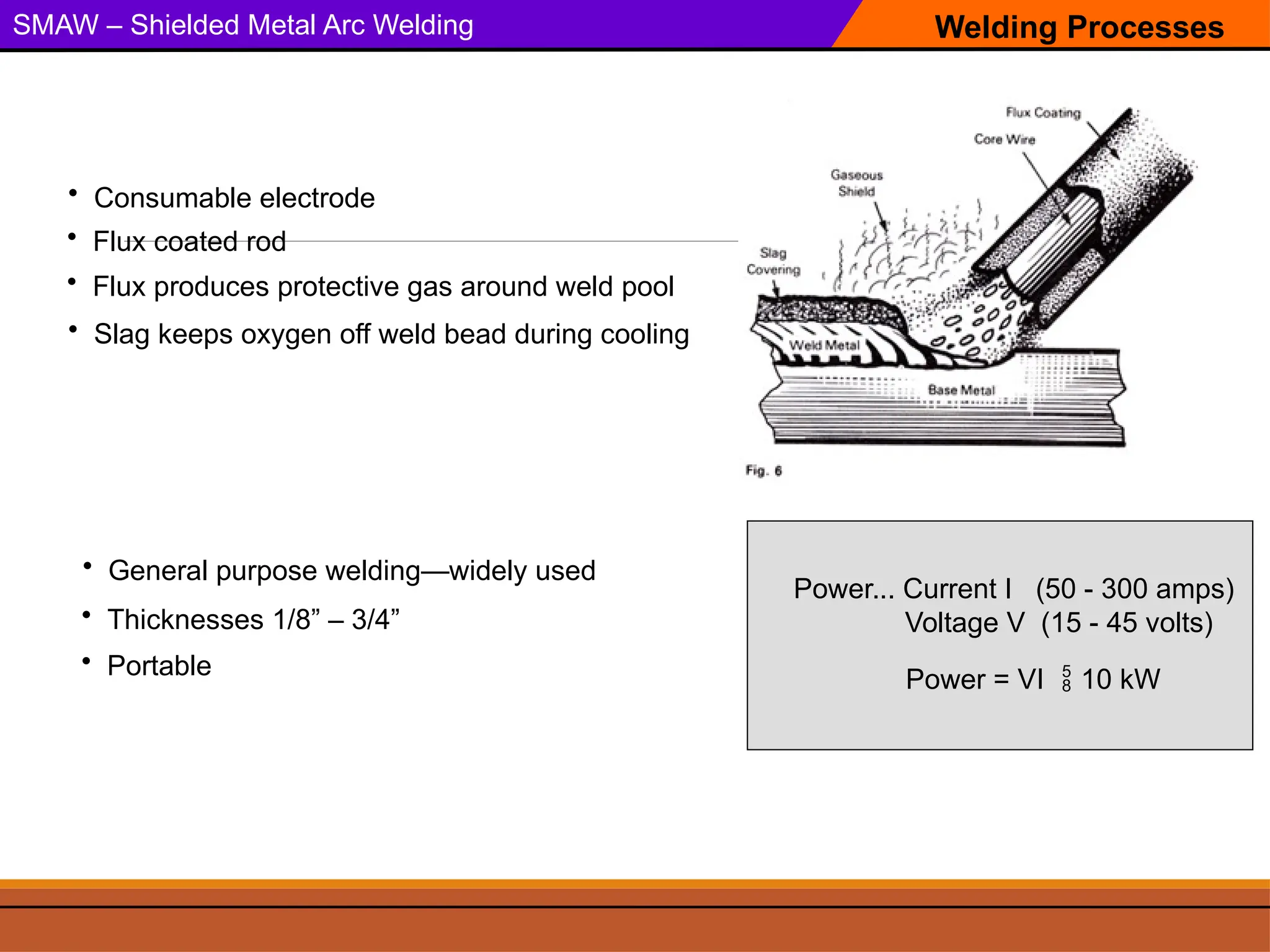

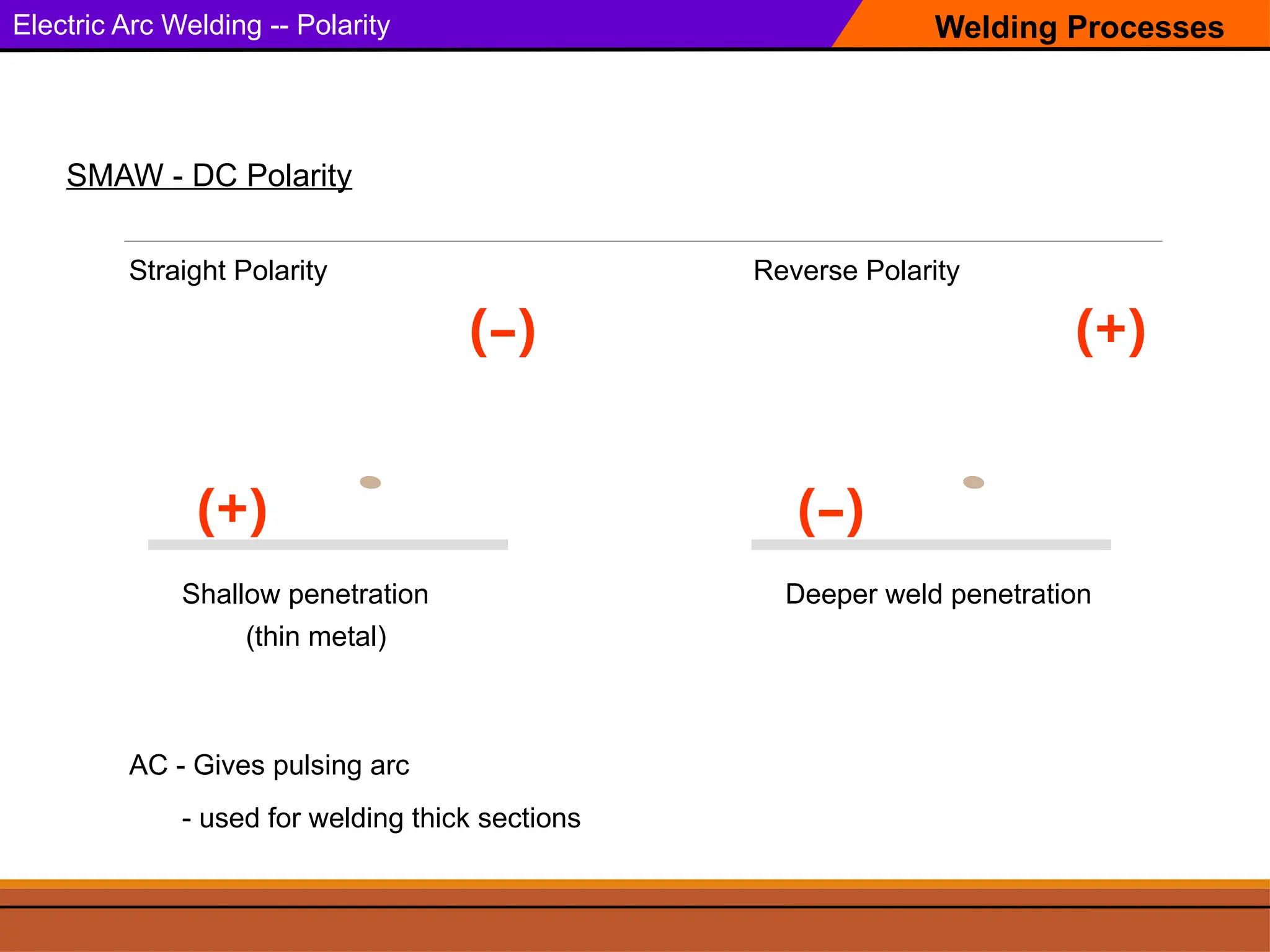

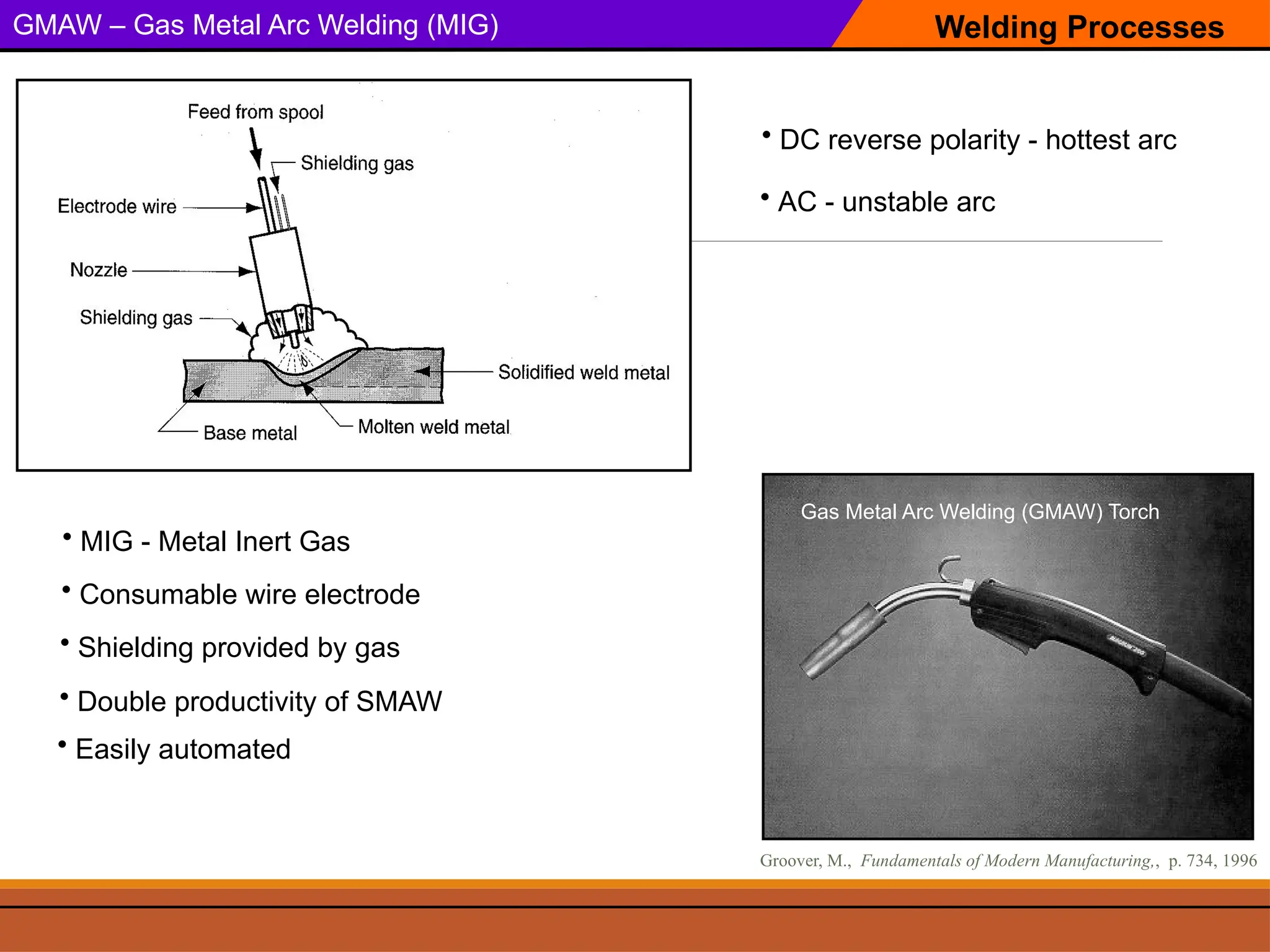

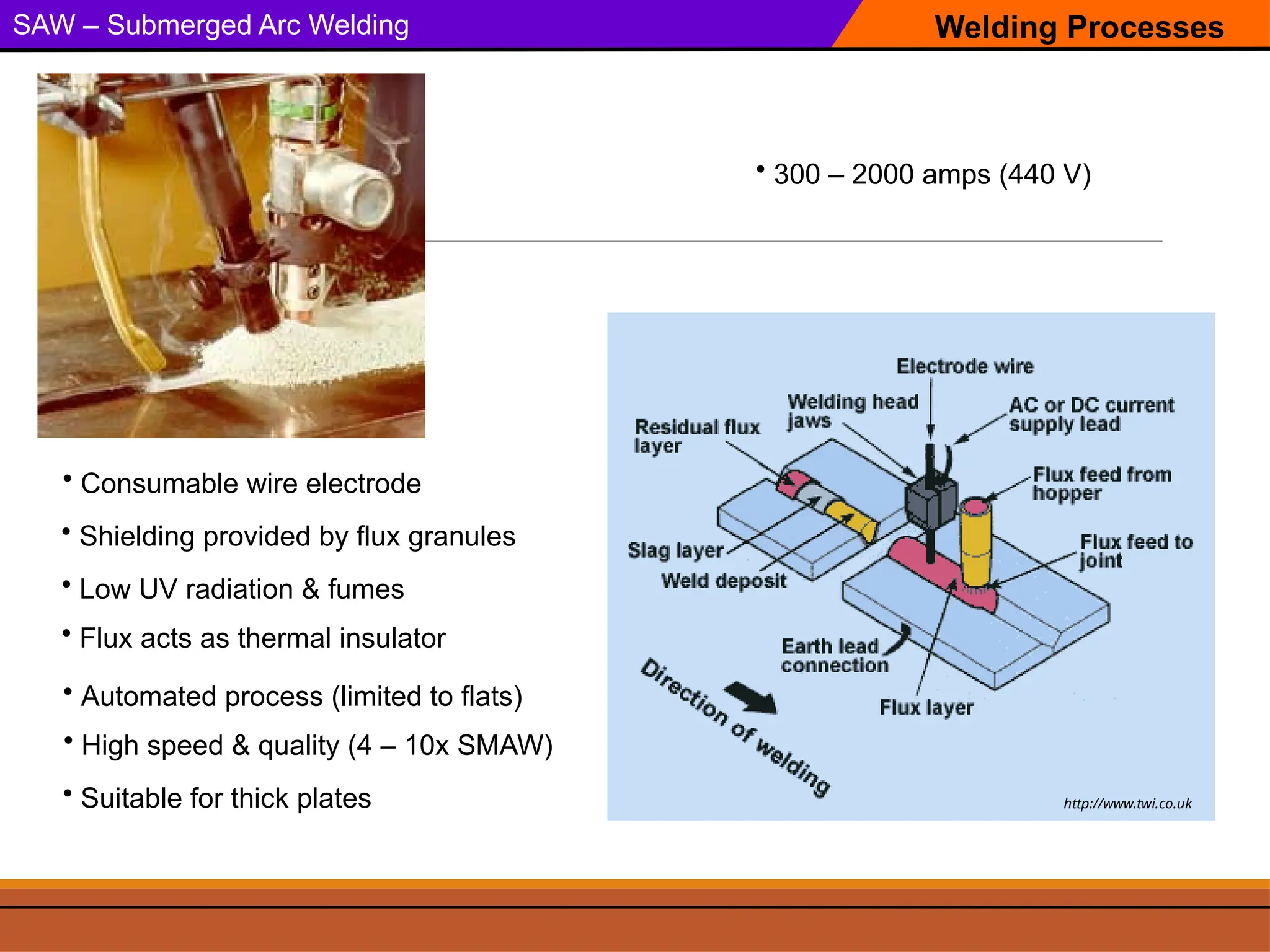

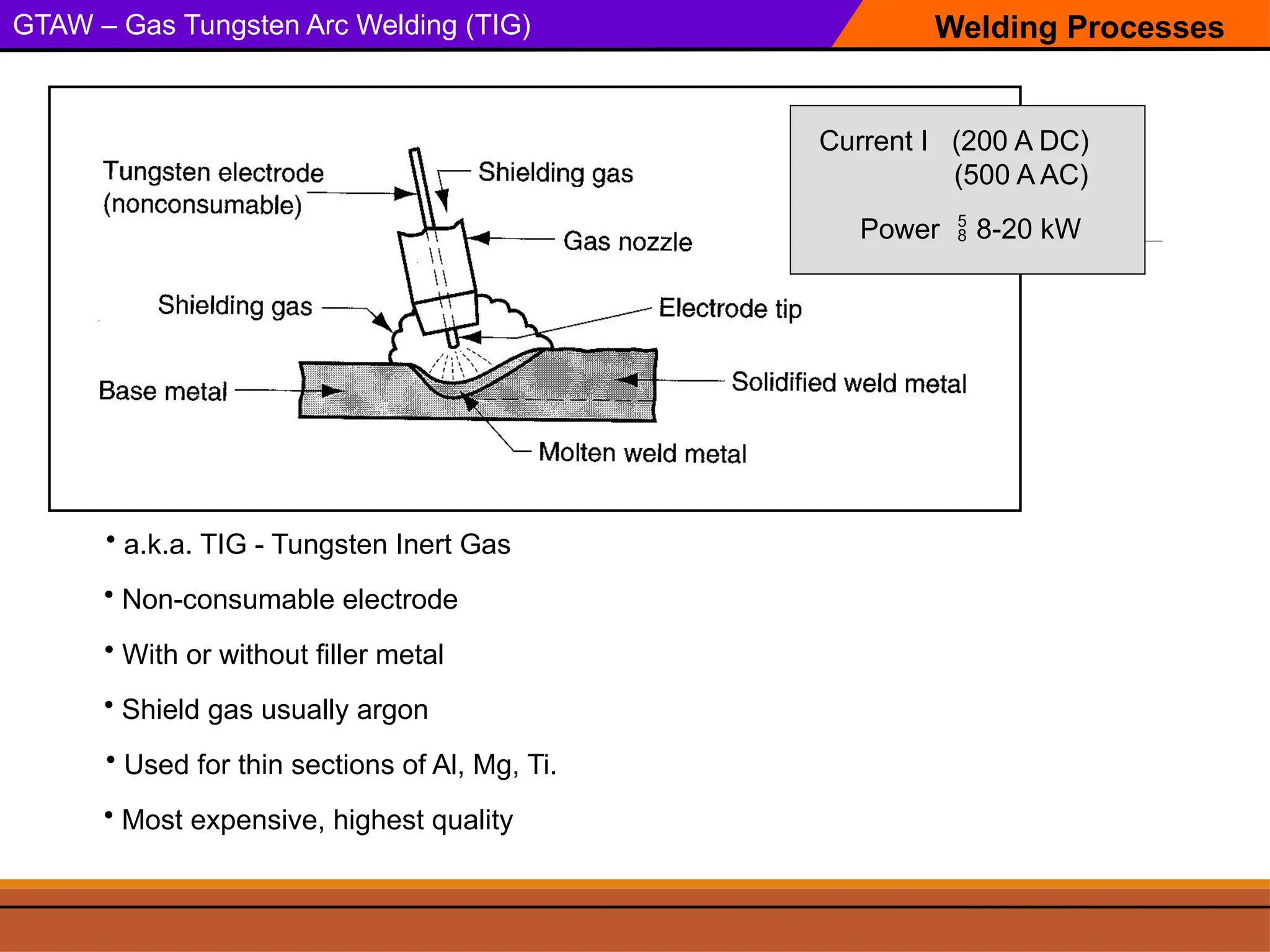

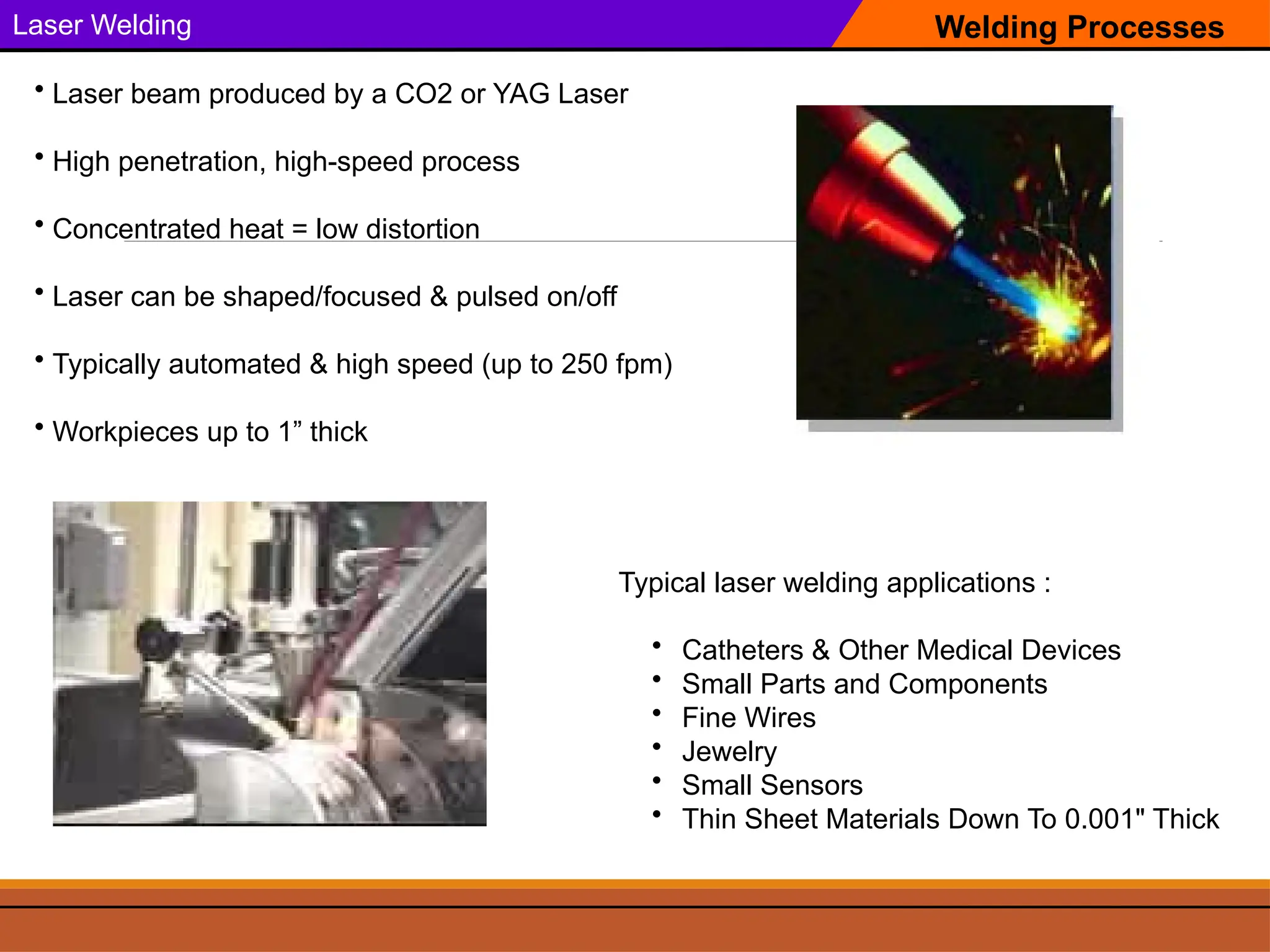

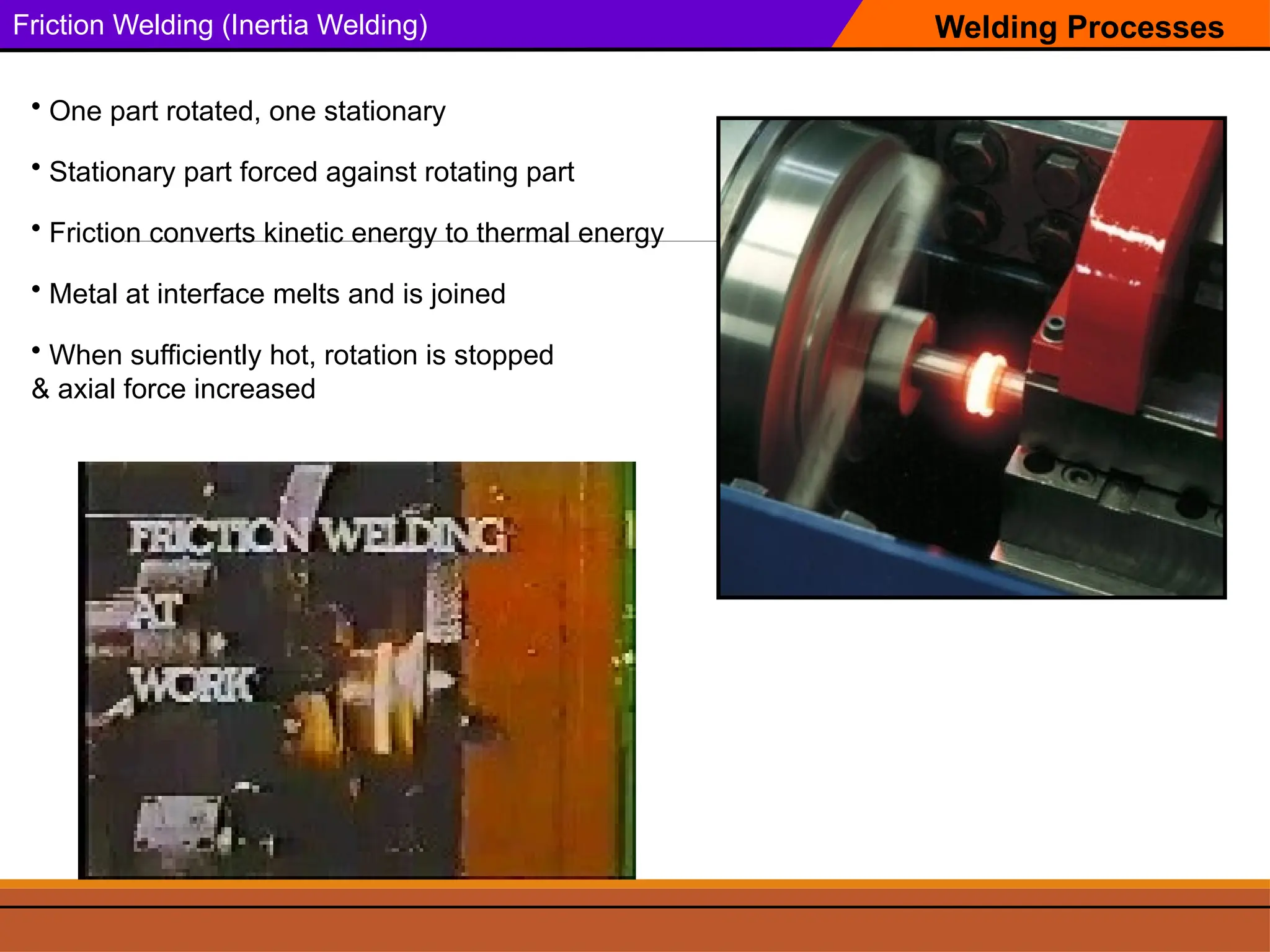

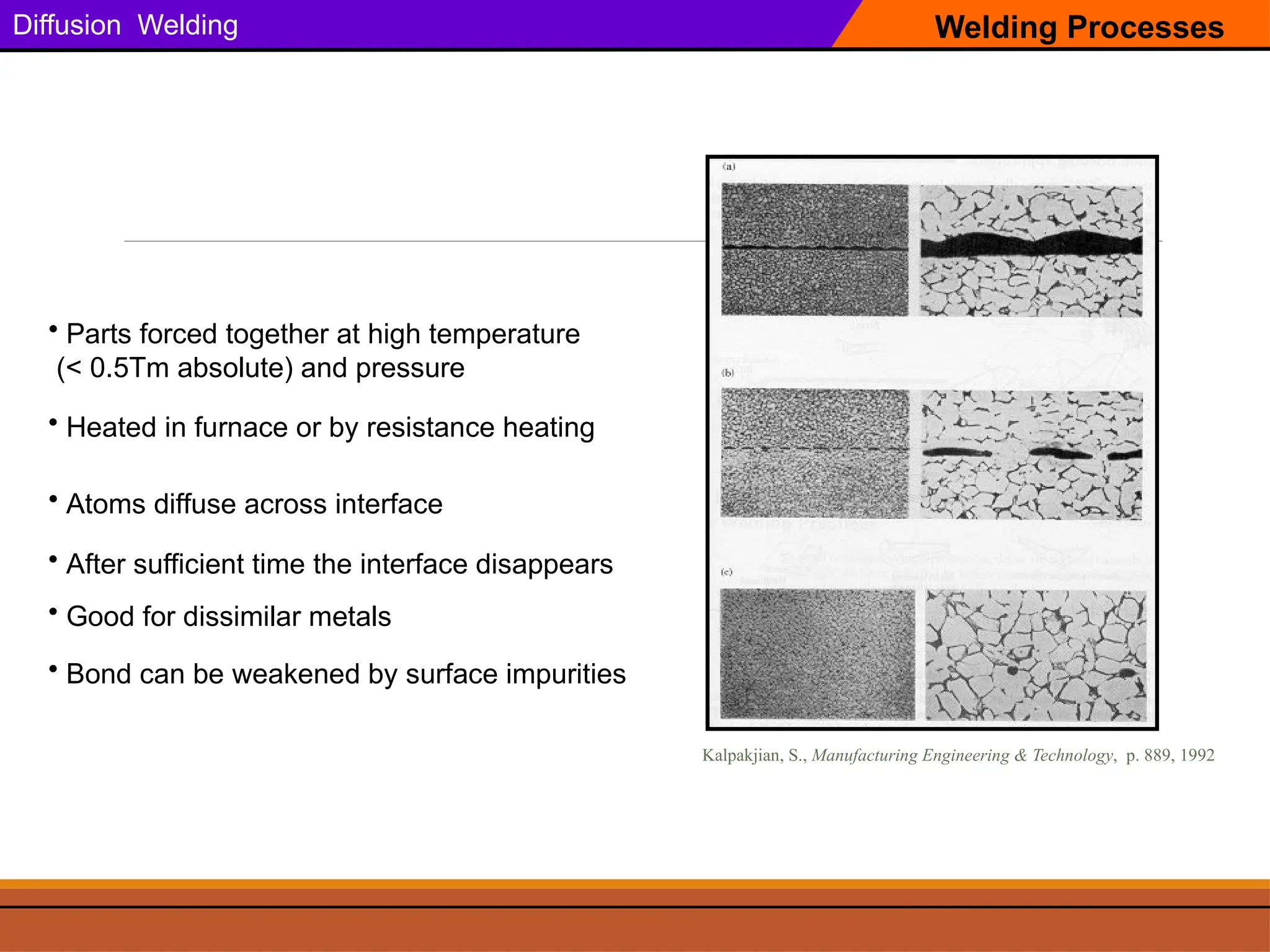

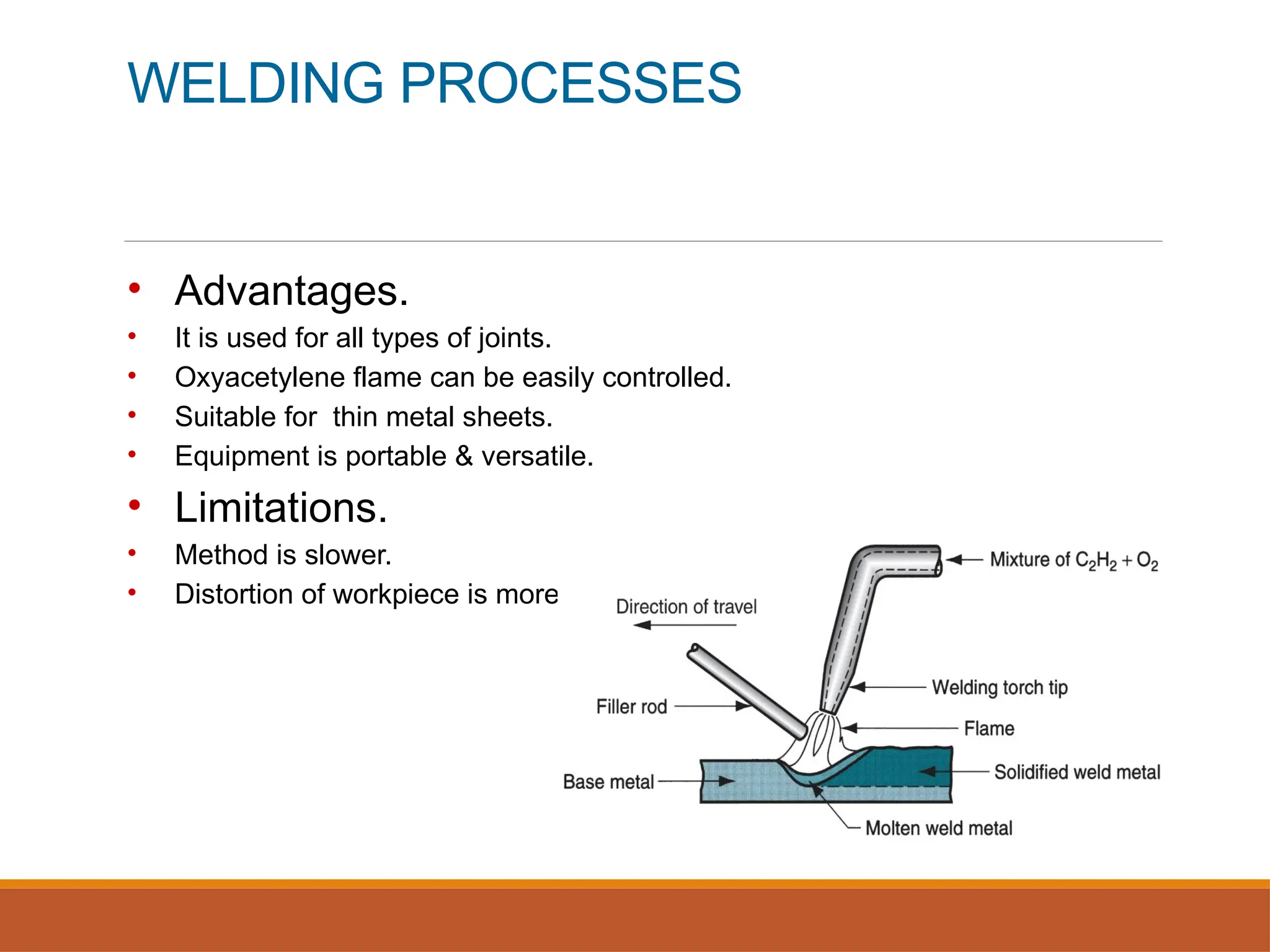

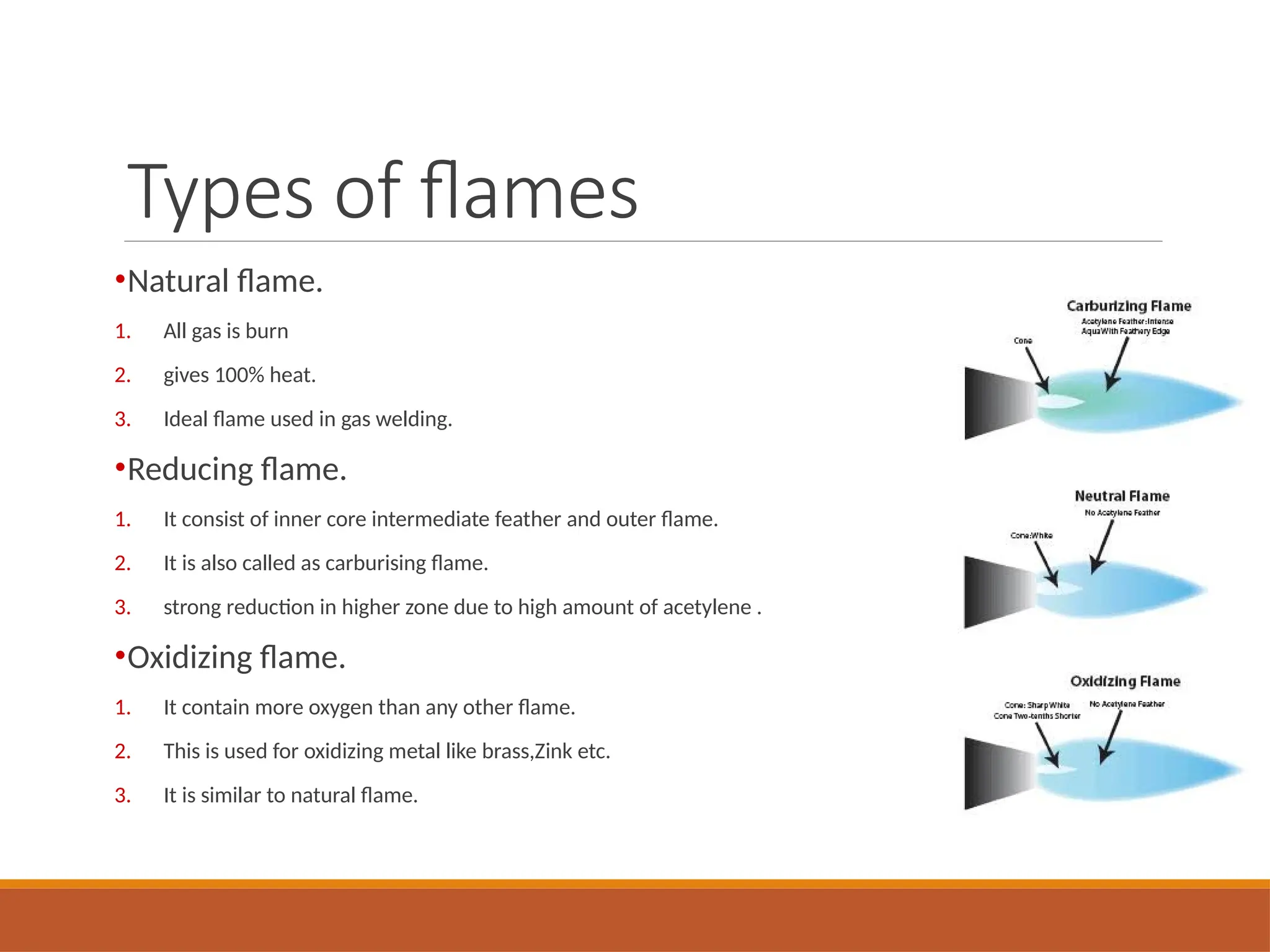

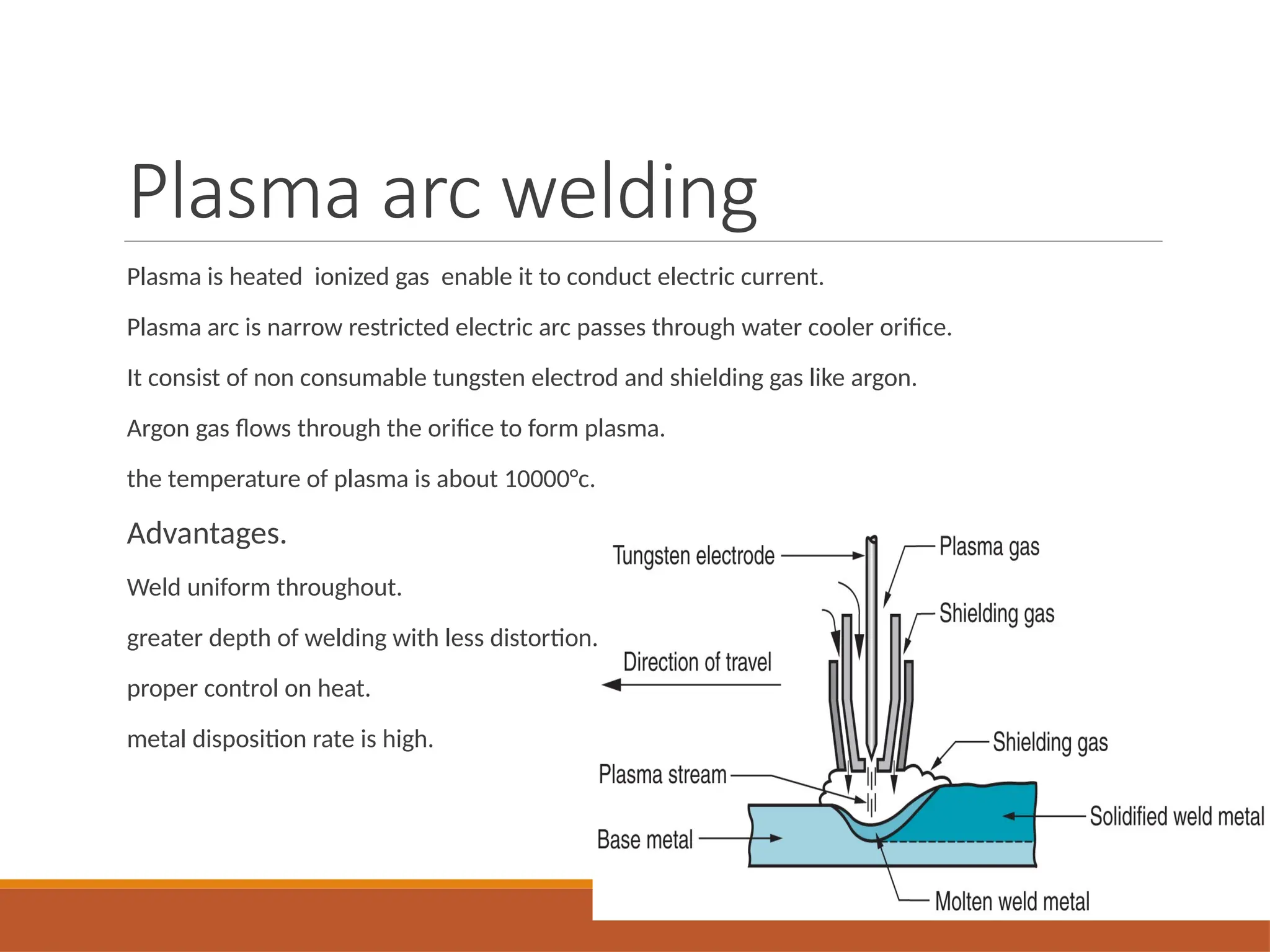

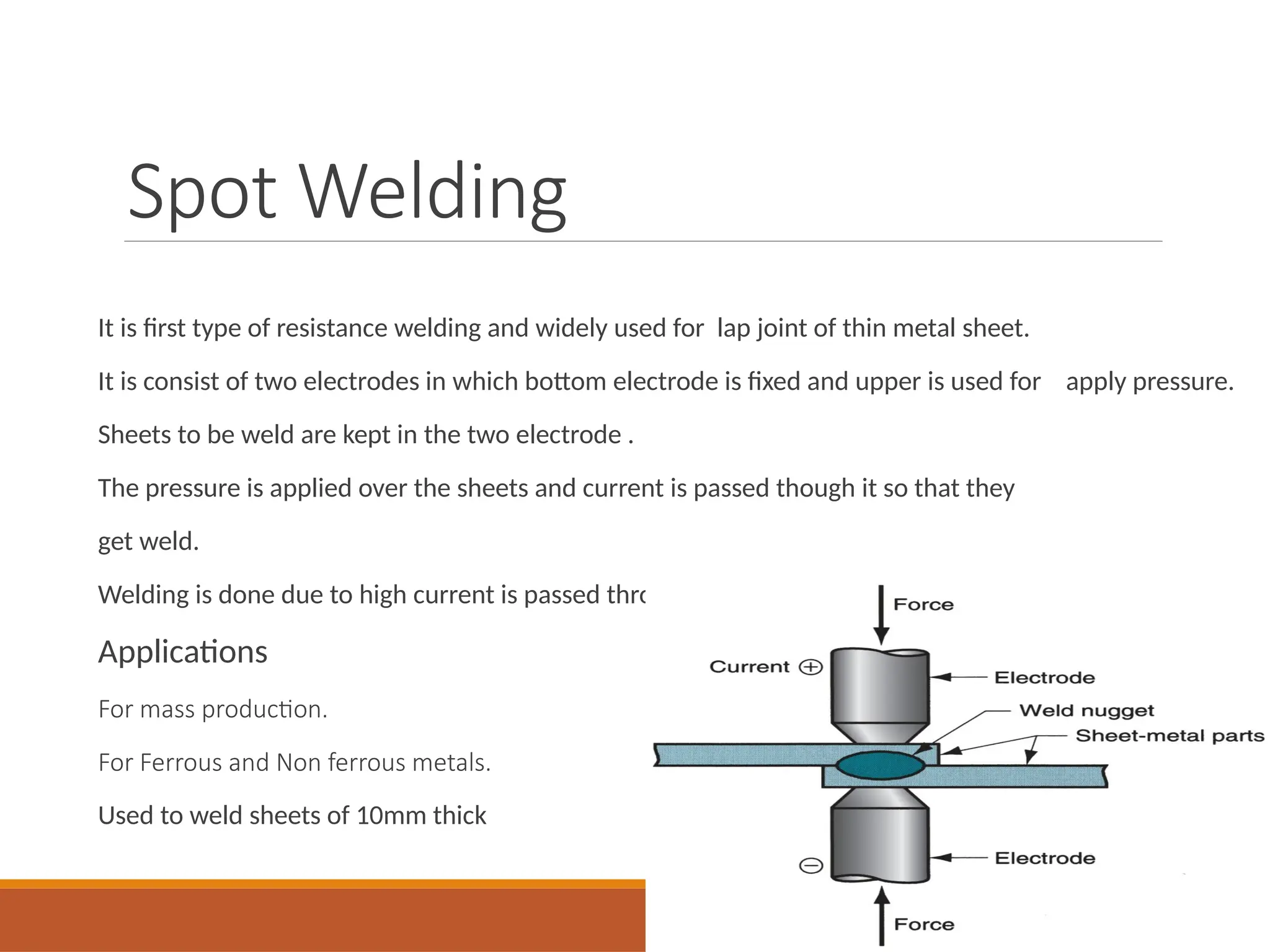

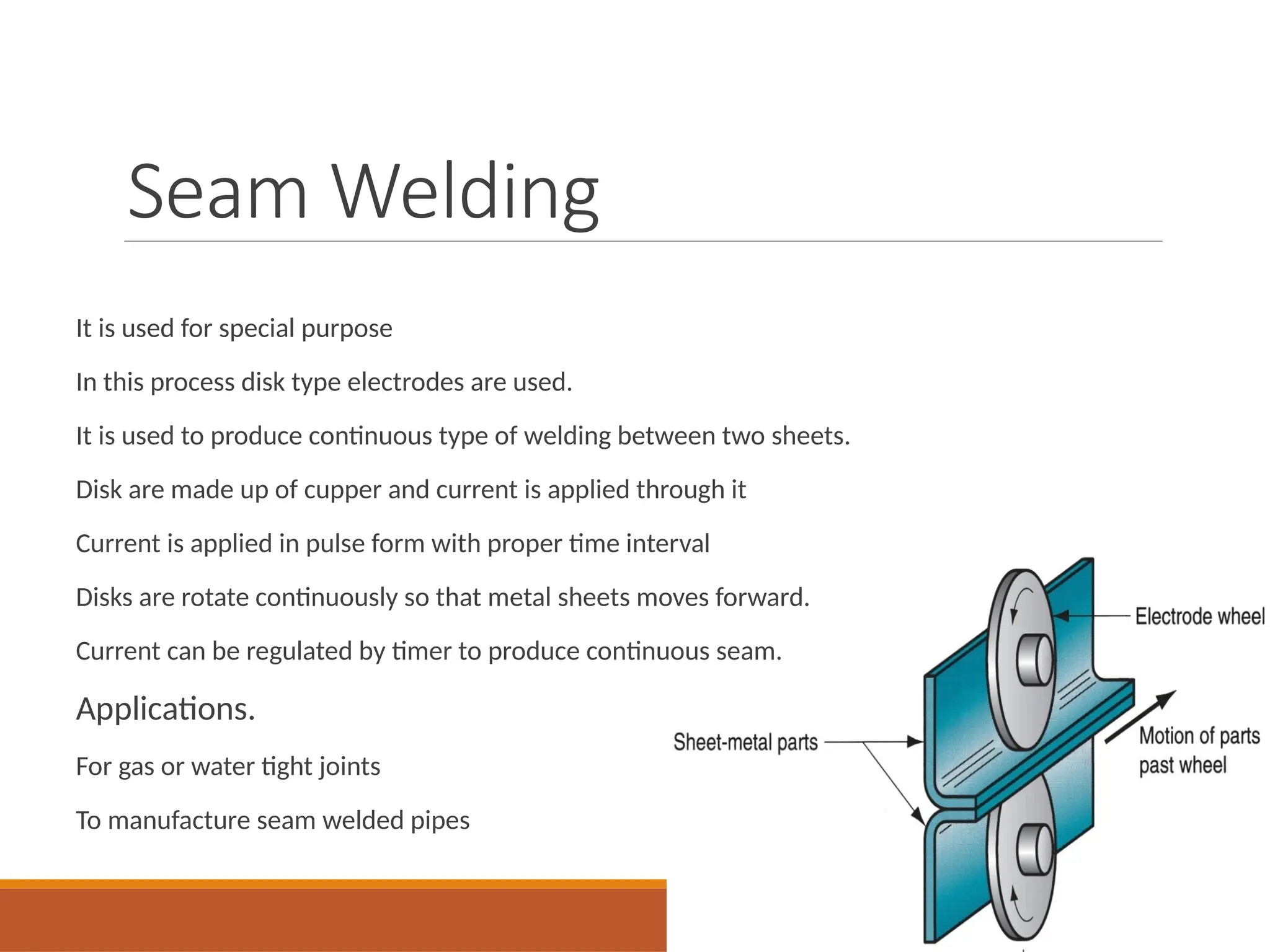

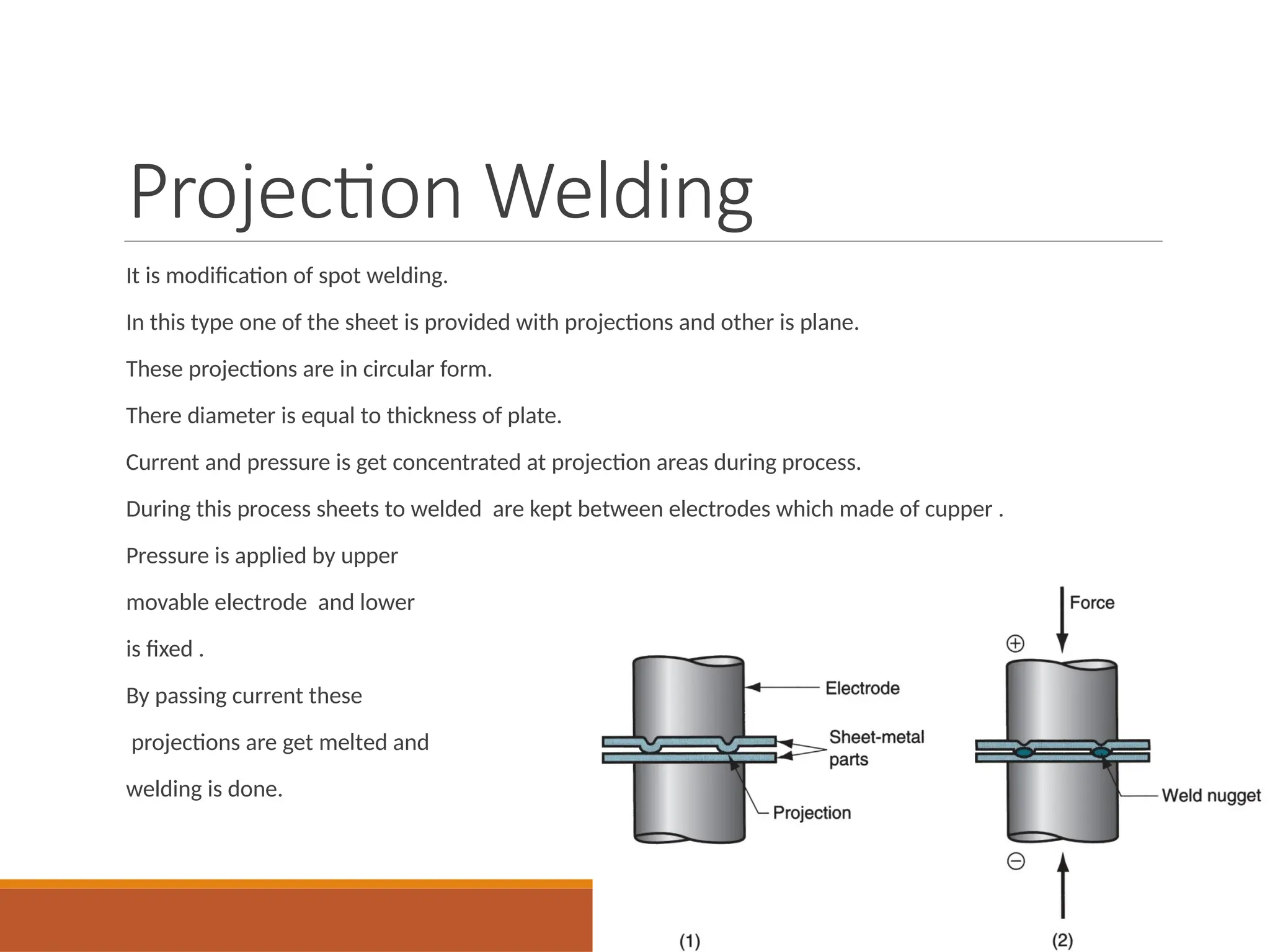

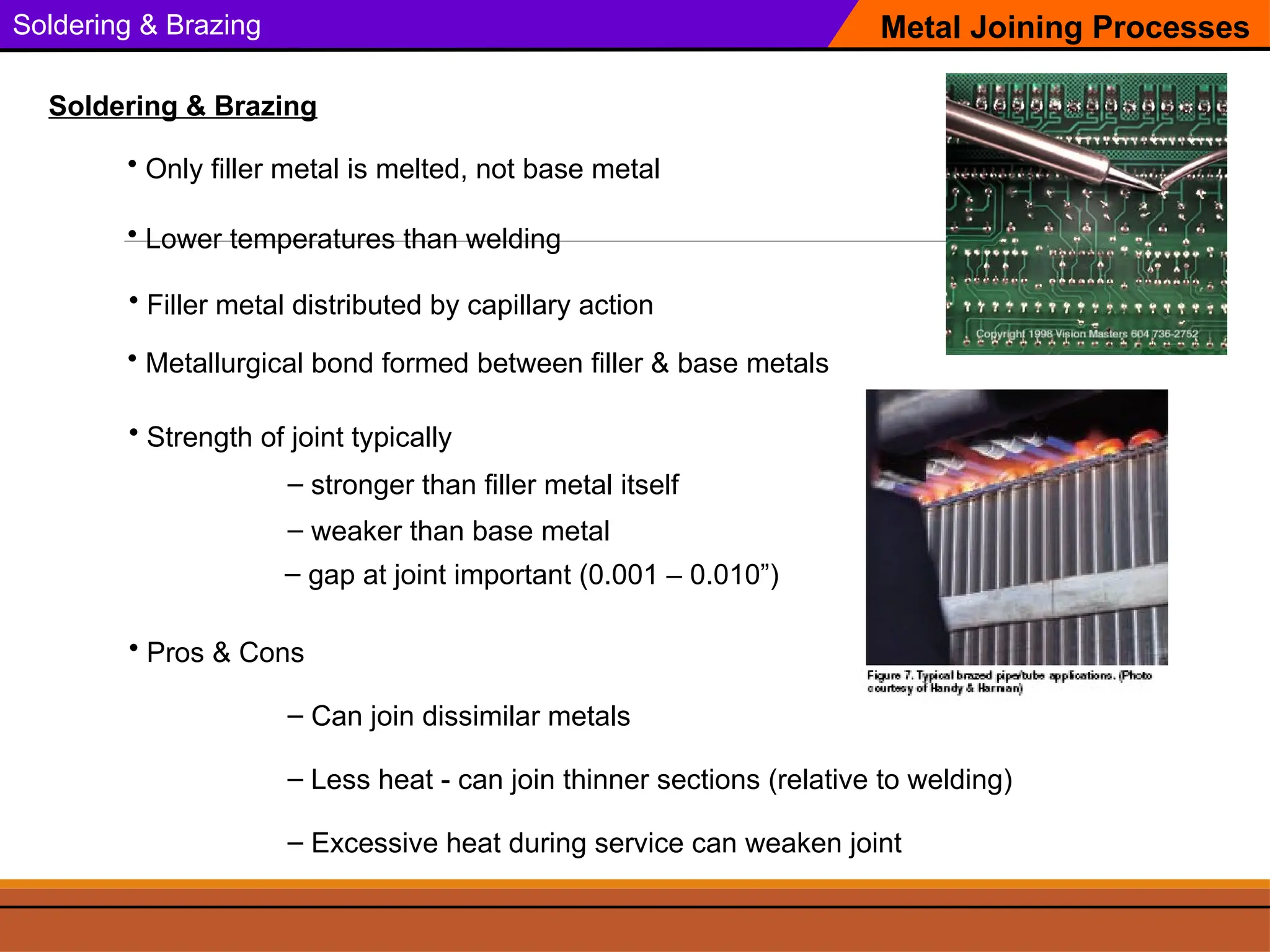

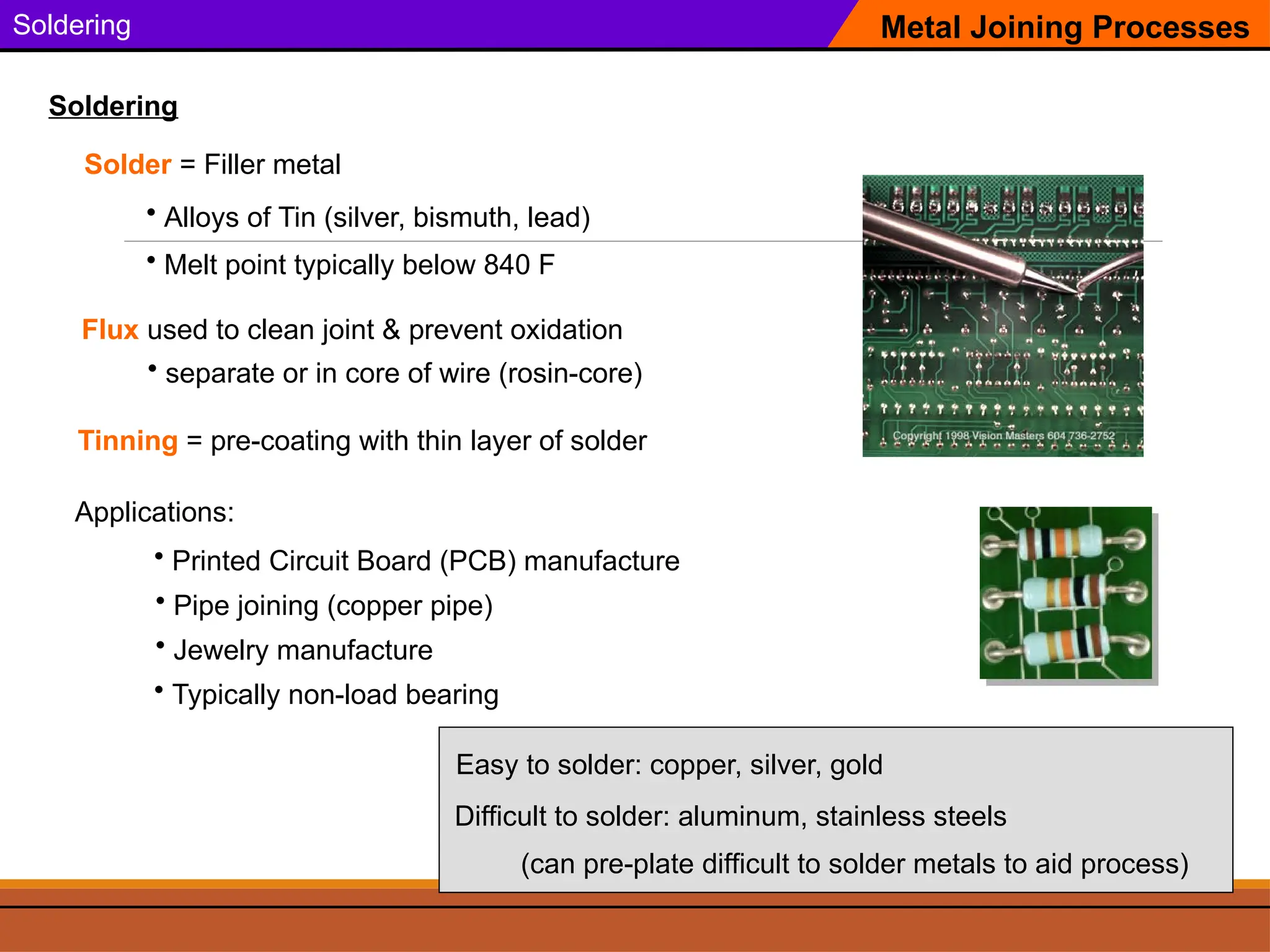

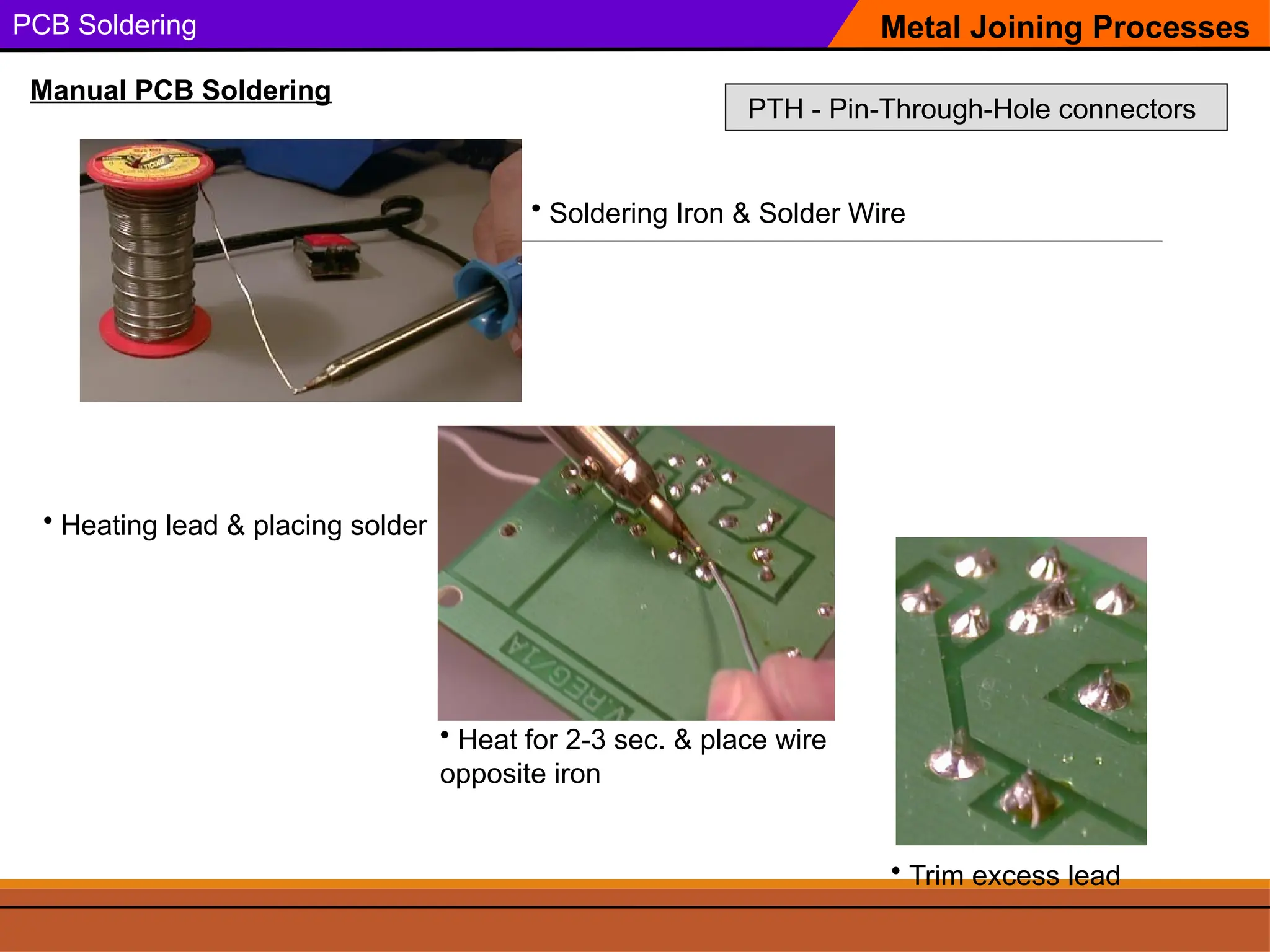

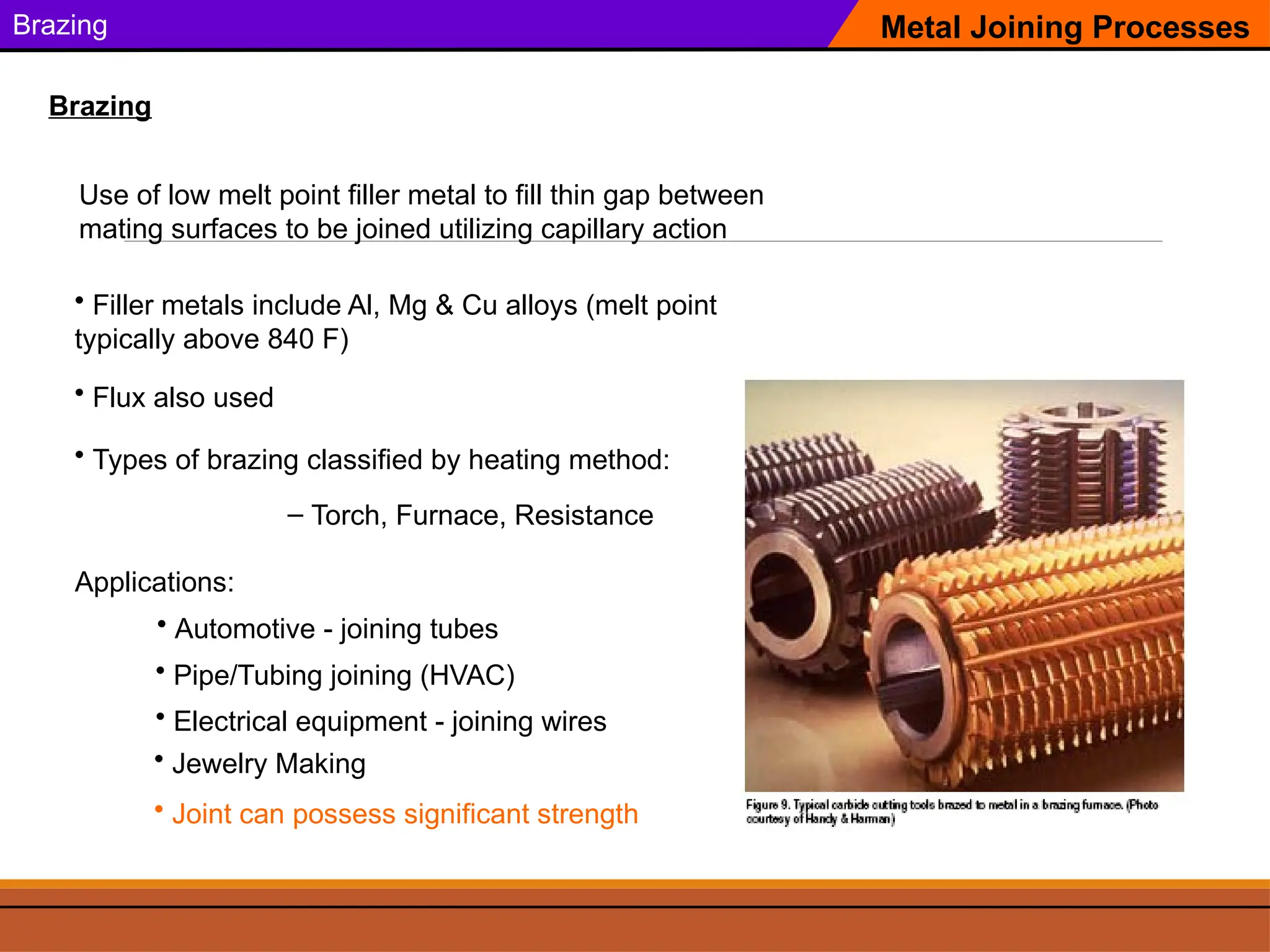

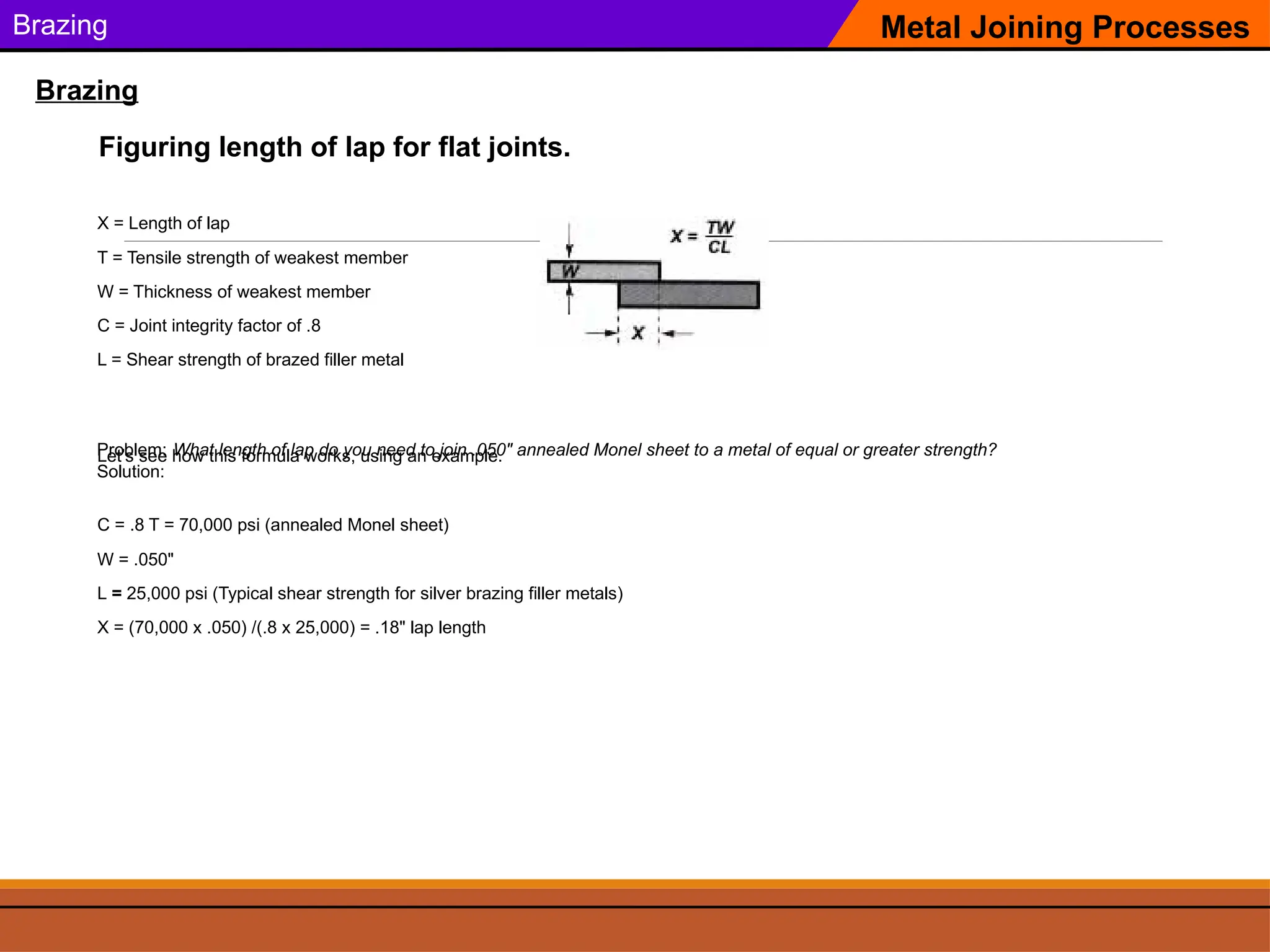

The document provides an overview of various welding methods used in fabrications, including fusion and solid-state welding processes, their advantages, and disadvantages. It outlines specific techniques such as gas metal arc welding, shielded metal arc welding, and resistance welding, detailing their applications and operational principles. Additionally, the document discusses soldering and brazing as metal joining processes, highlighting their uses, materials, and joint integrity calculations.