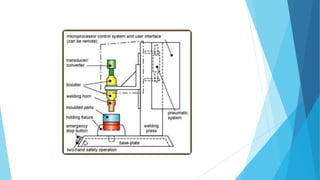

Ultrasonic welding uses high-frequency sound waves to join materials together without melting them. It works by placing materials under pressure between a horn and anvil, which vibrate at ultrasonic frequencies, causing the materials' molecules to rub and form a solid bond. It is commonly used for plastics and dissimilar materials. Advantages are that it is faster than adhesives and leaves clean welds, while disadvantages are that it is limited to thin metals and not suitable for large welds. Applications include bonding thermoplastics in electronics, automotive, medical, and packaging industries.