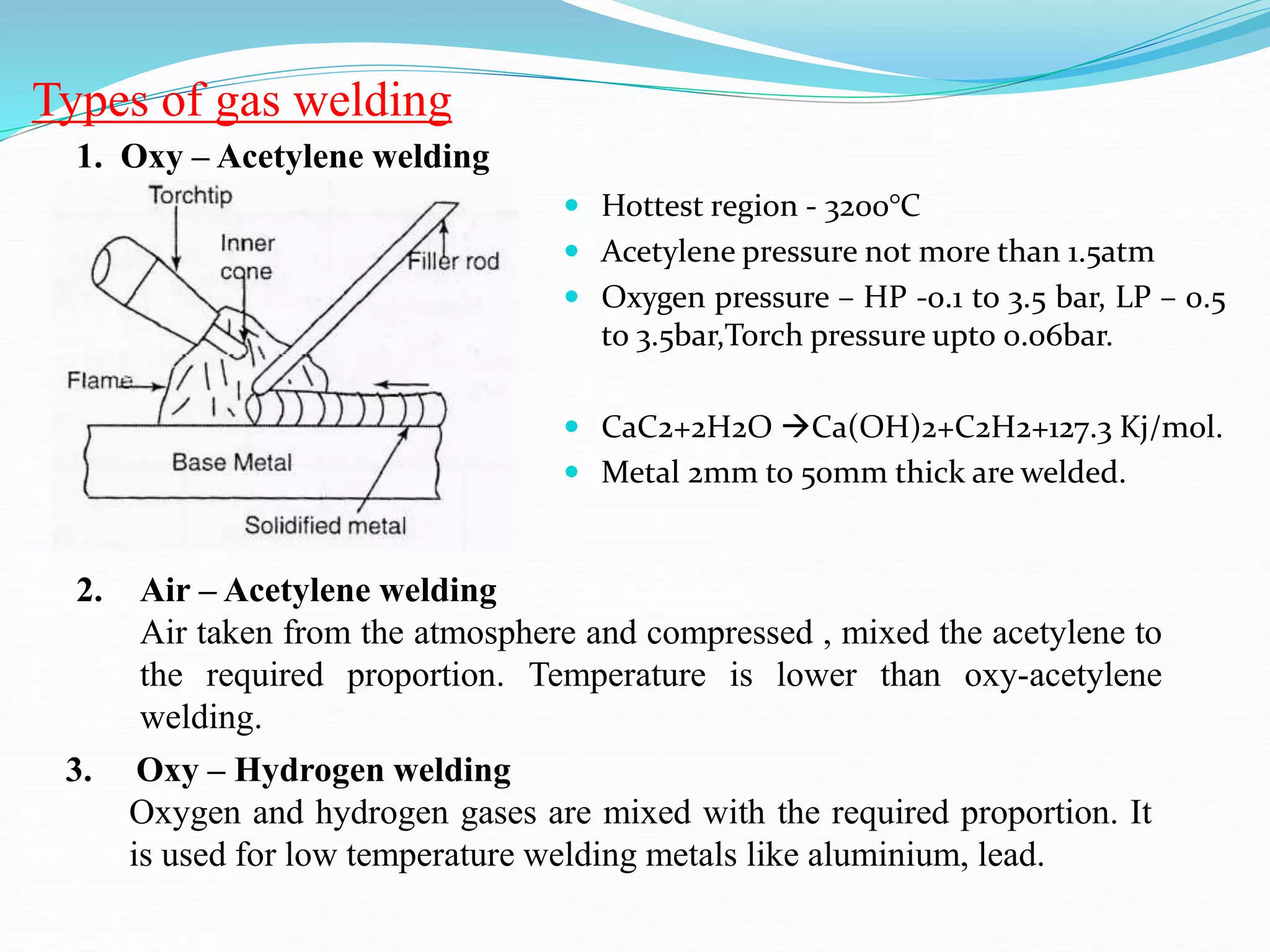

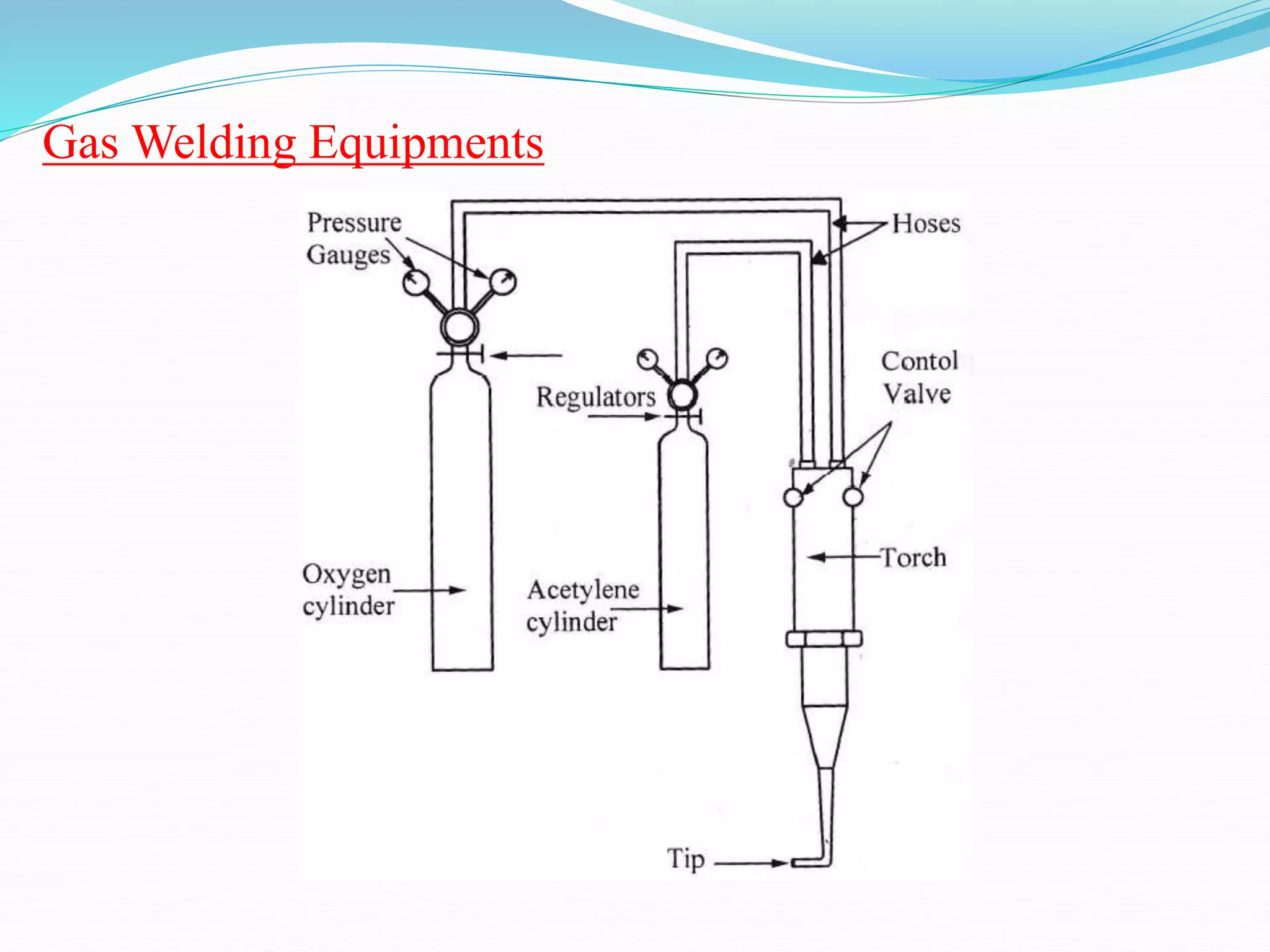

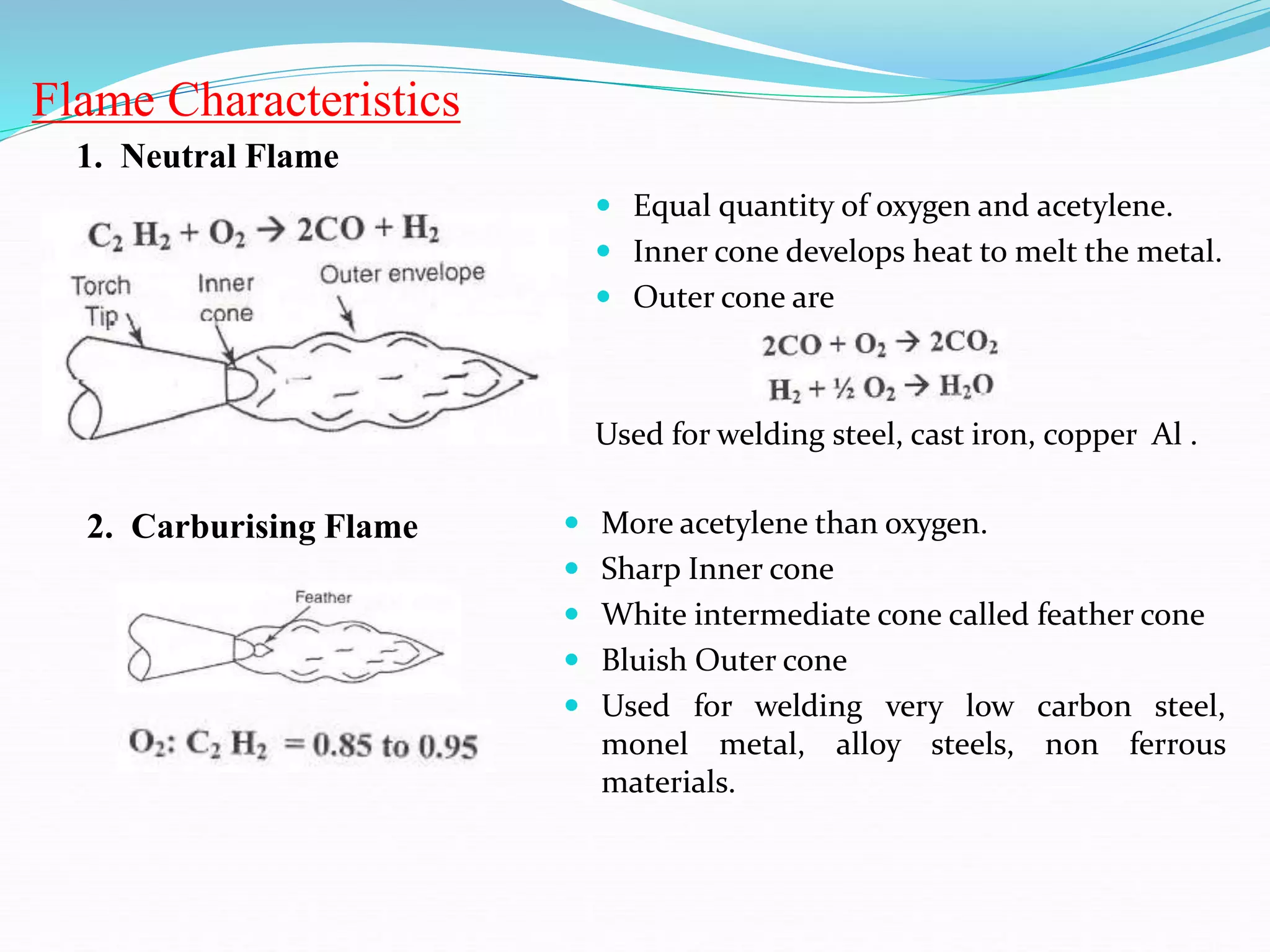

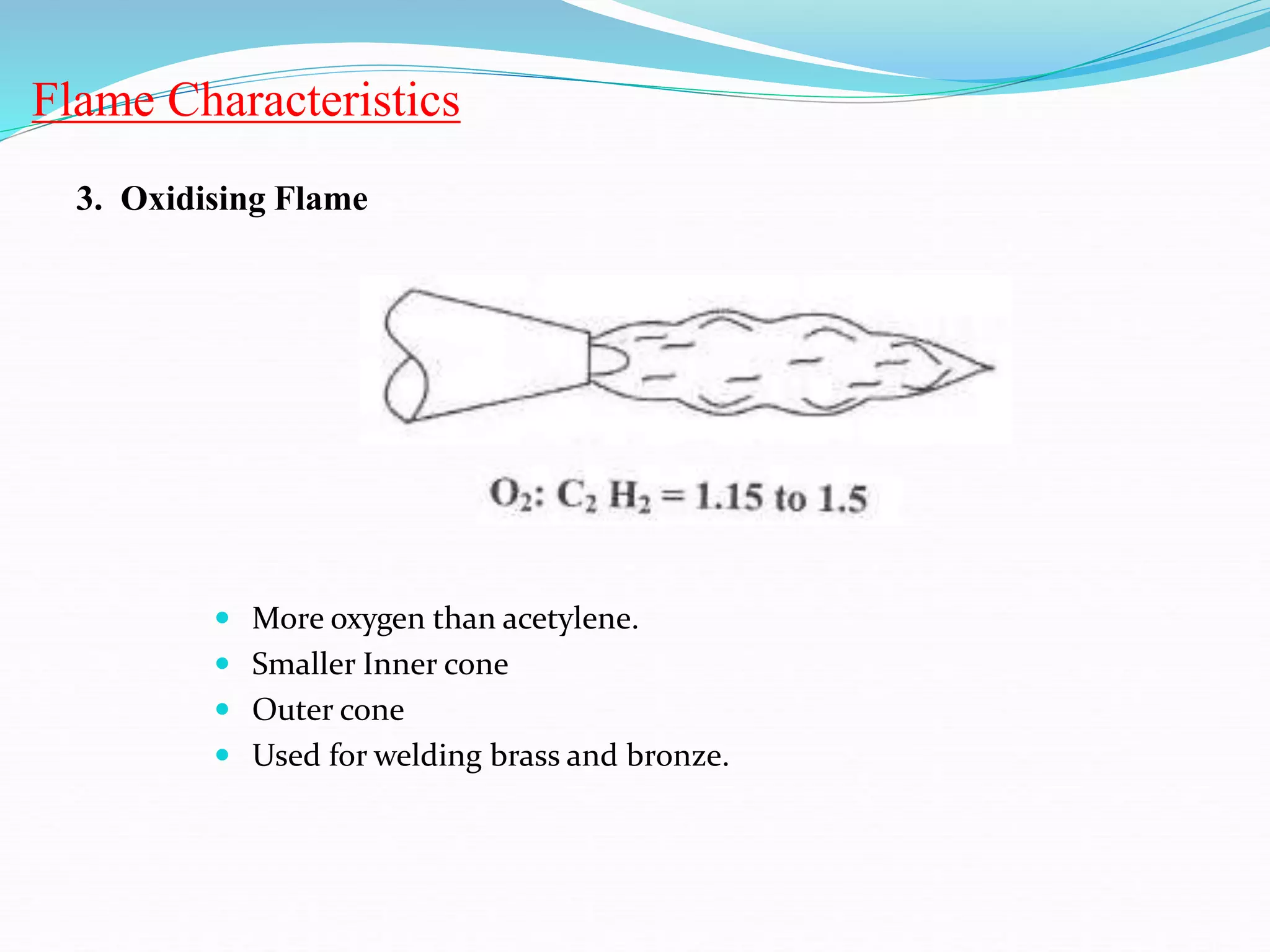

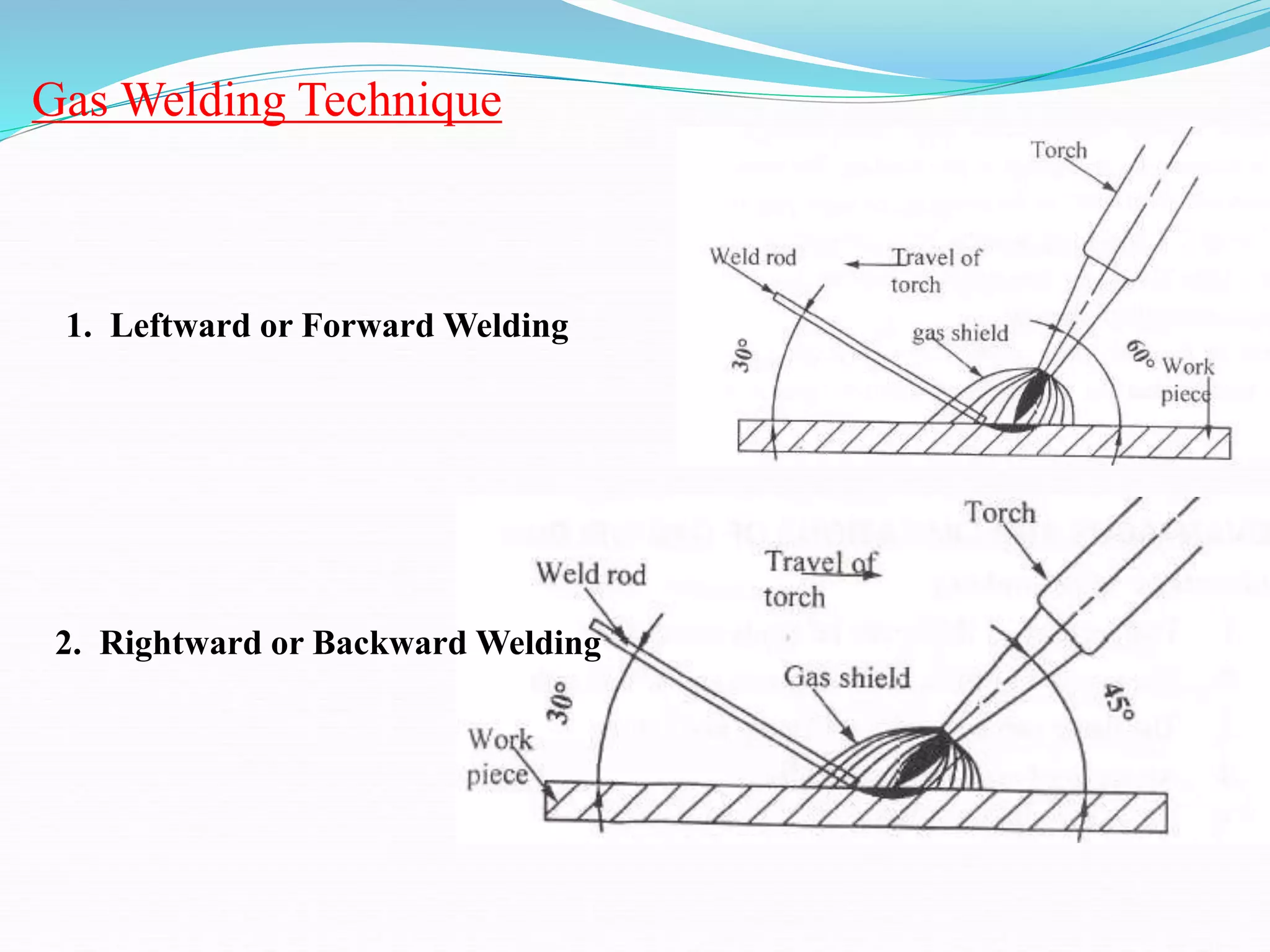

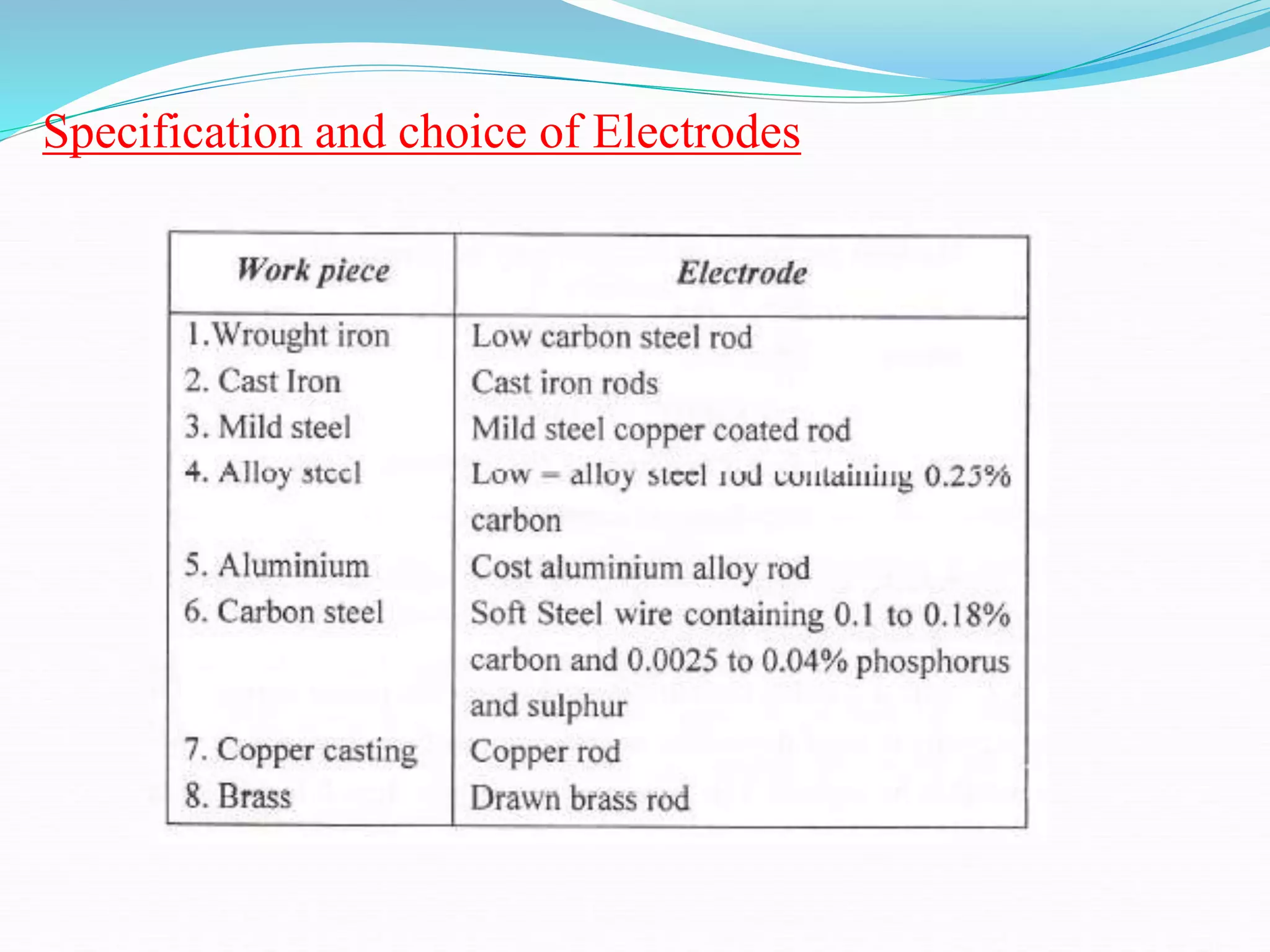

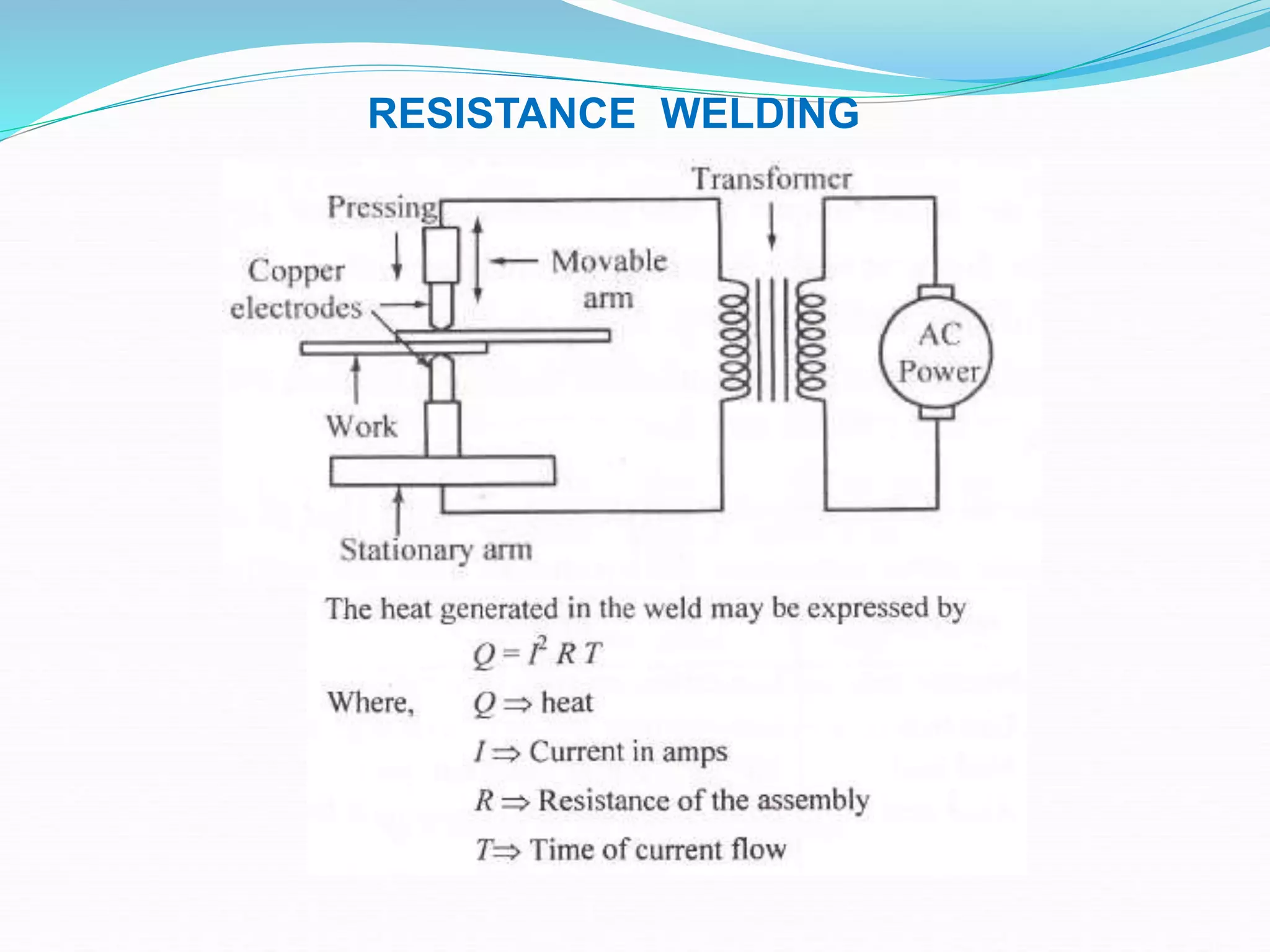

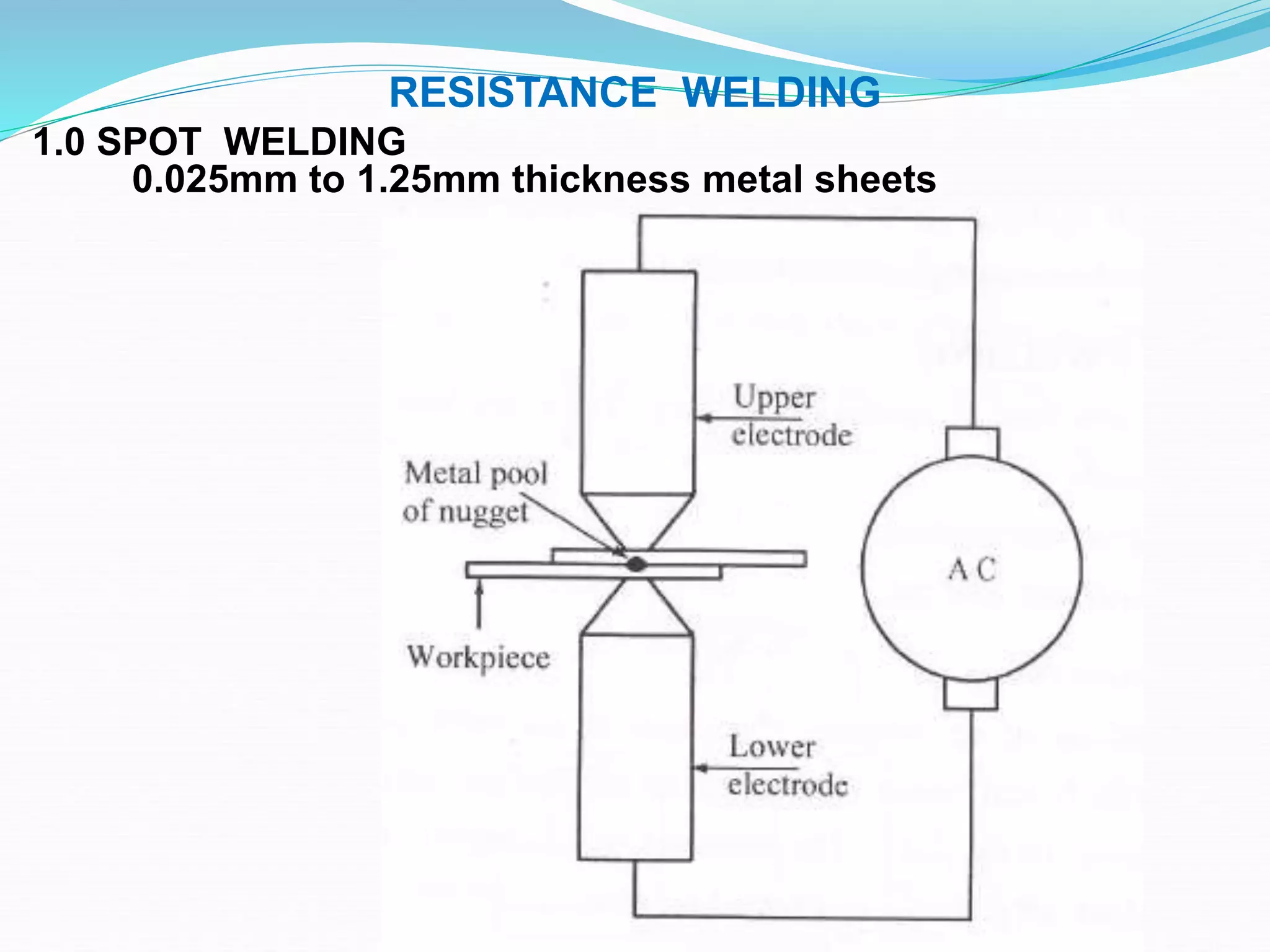

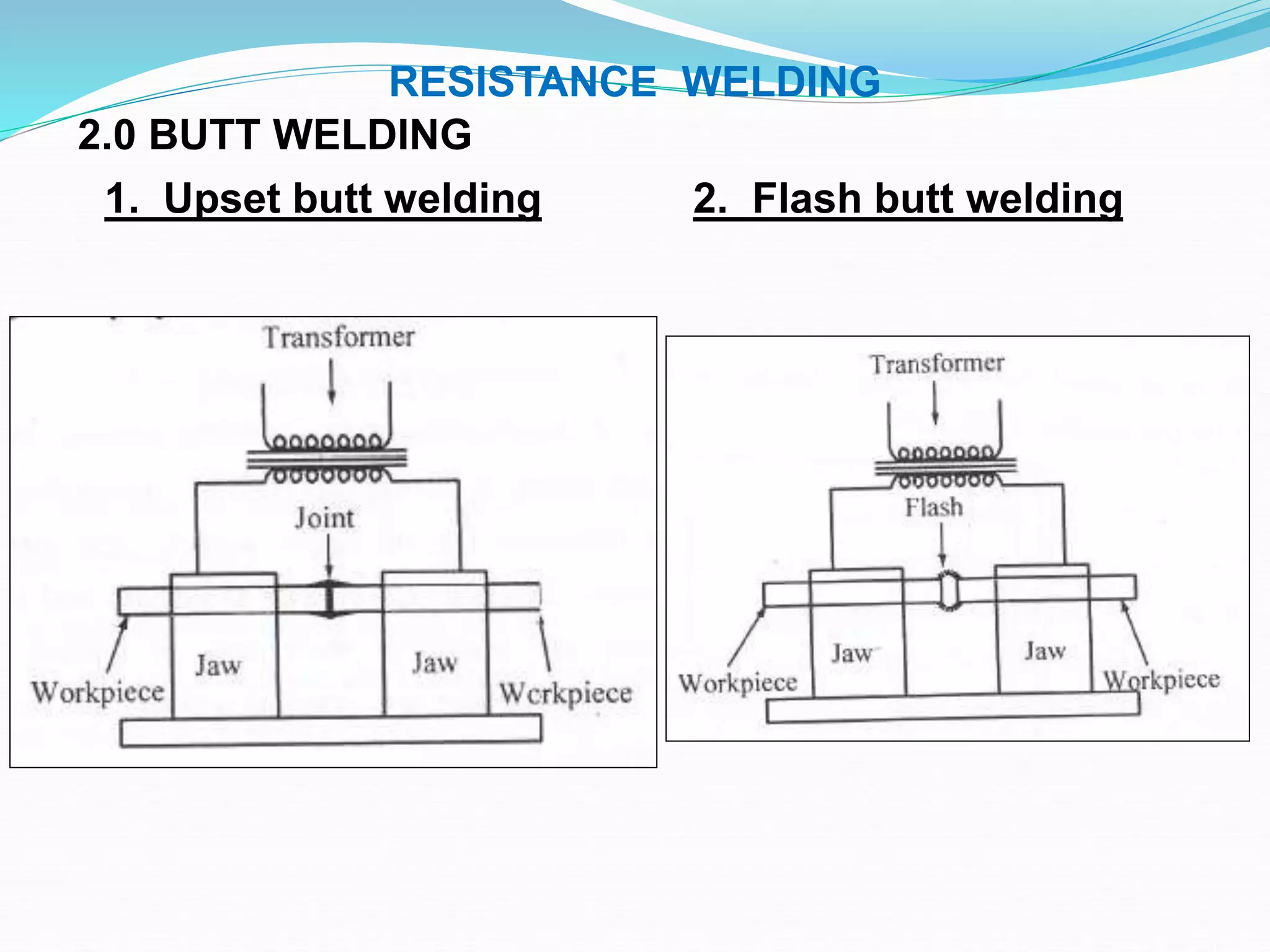

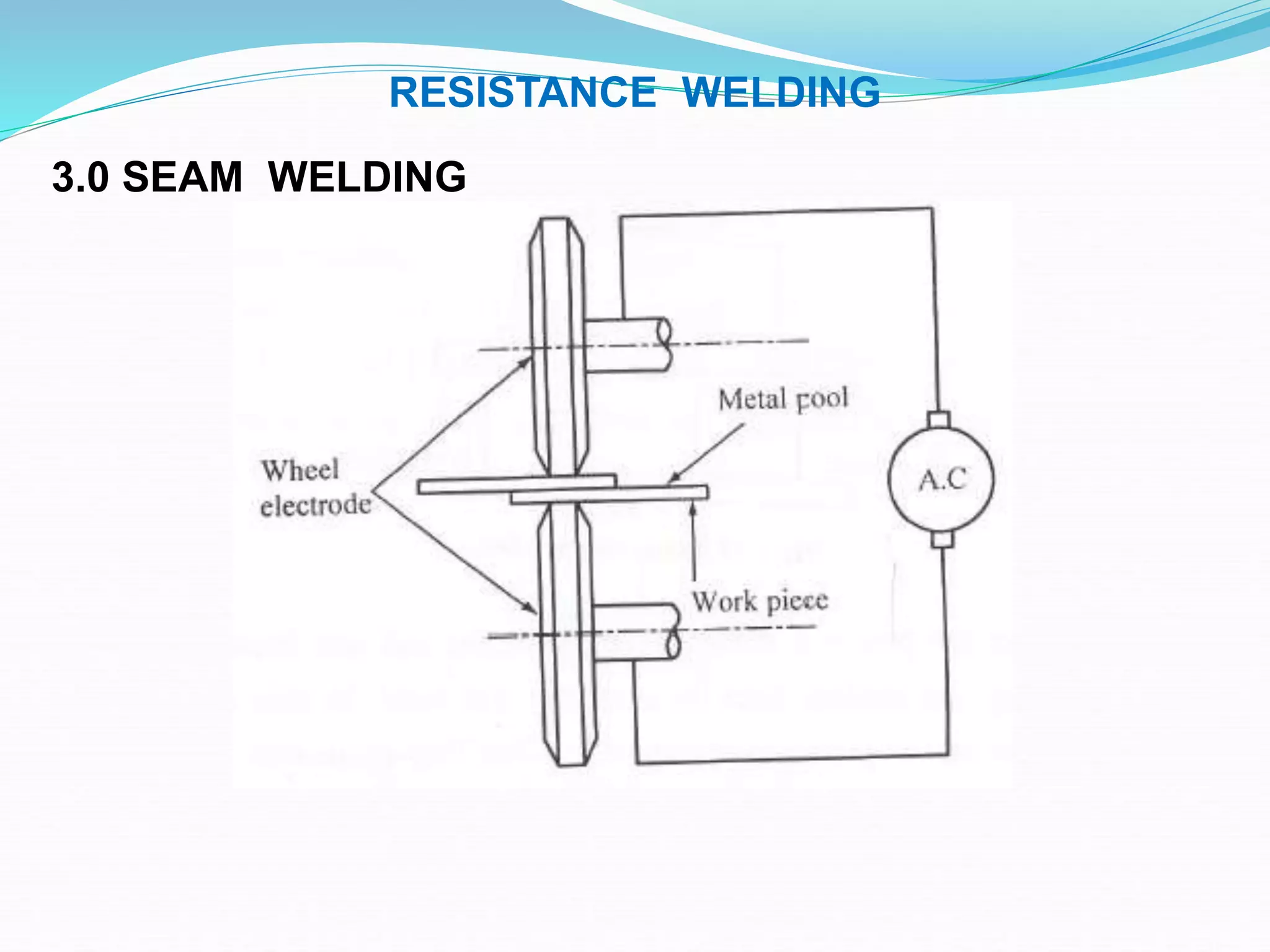

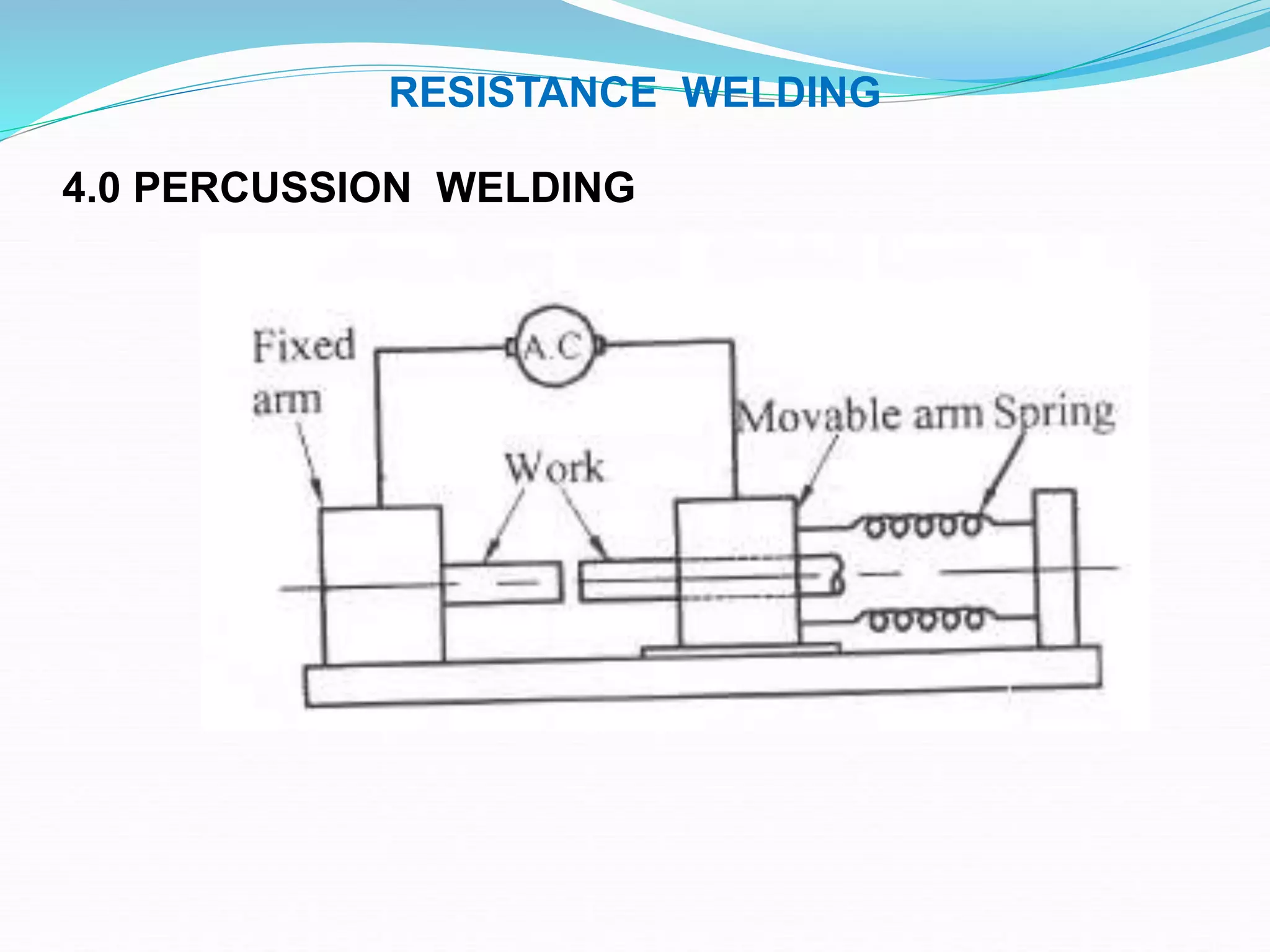

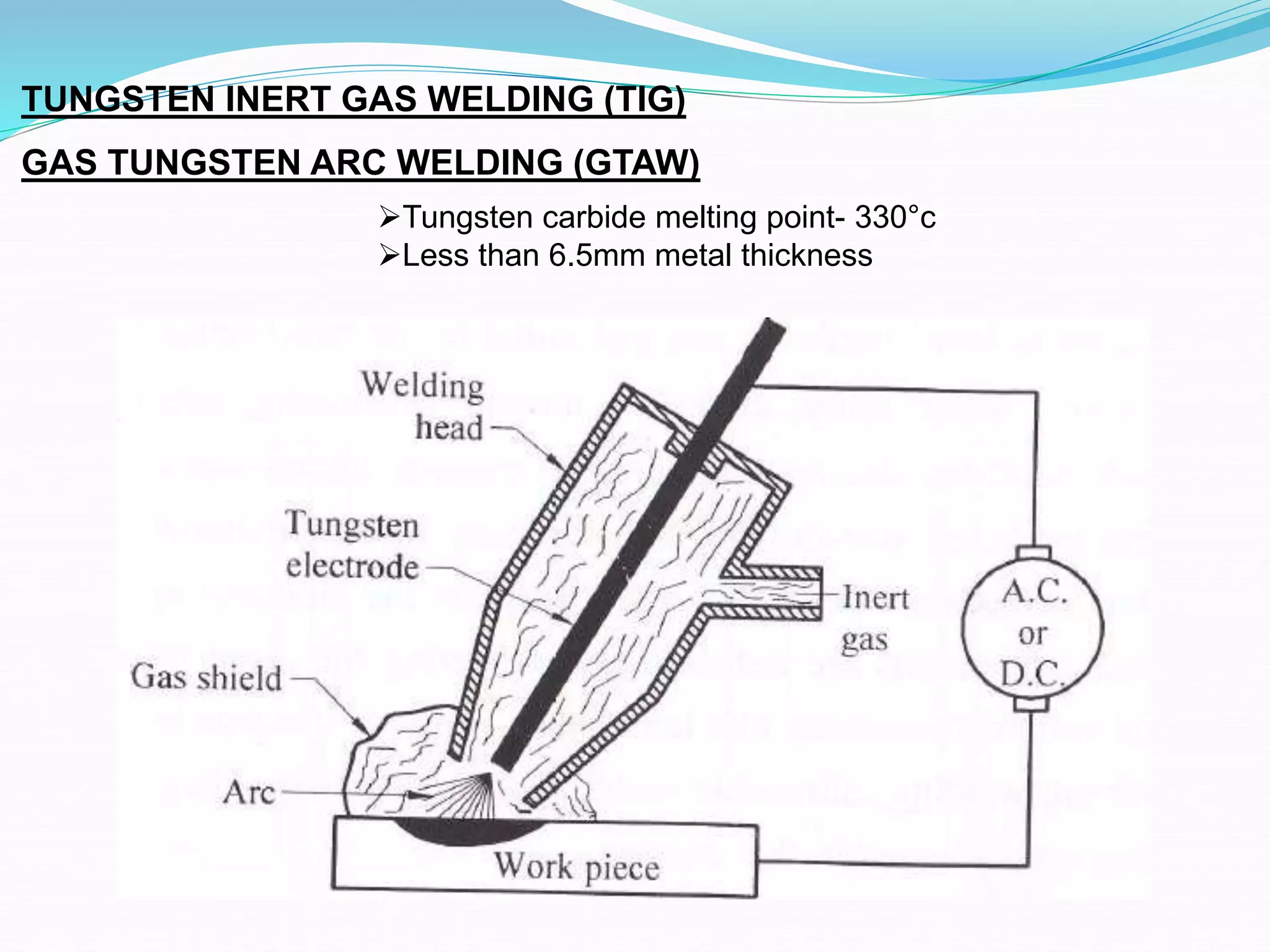

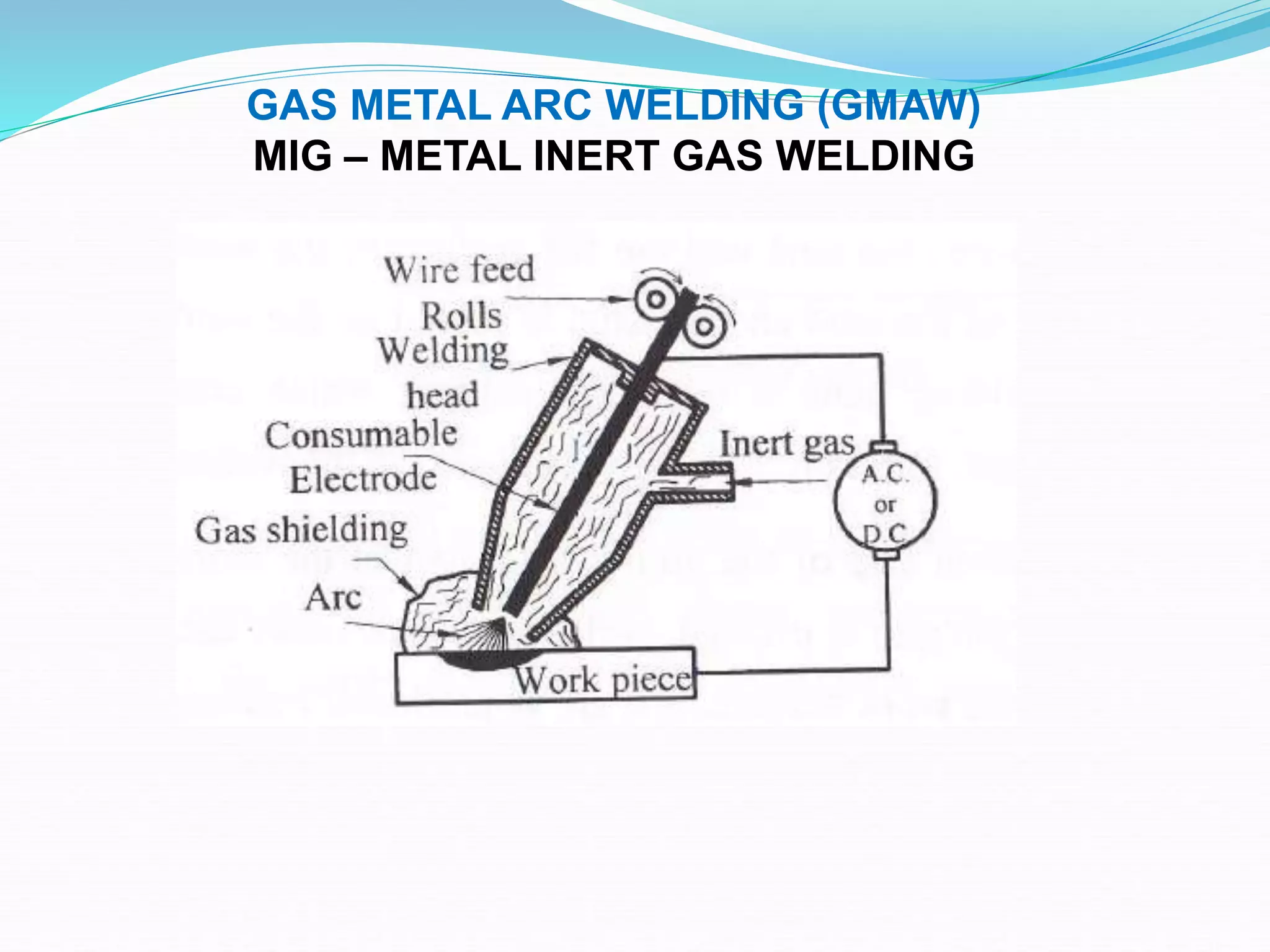

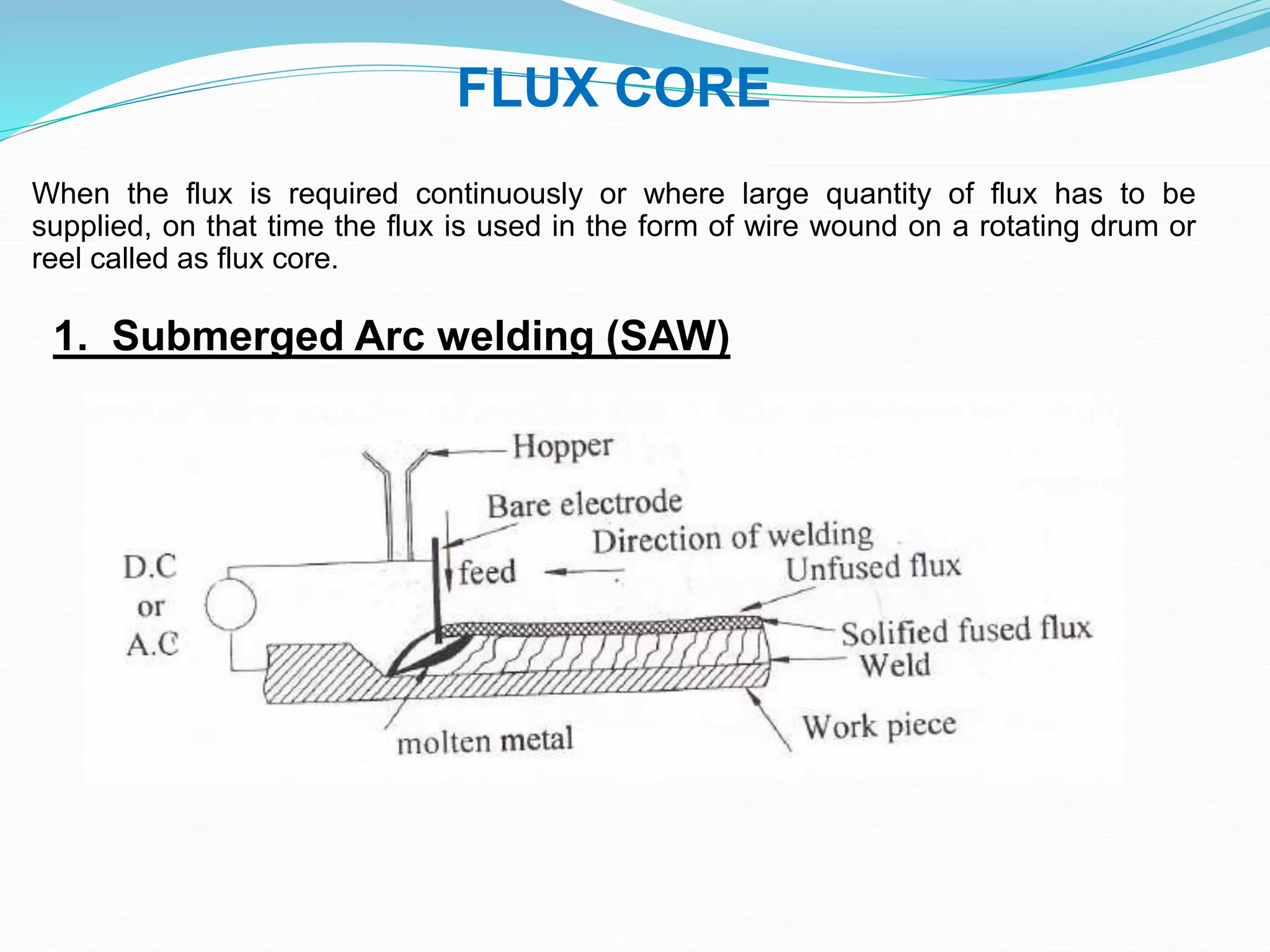

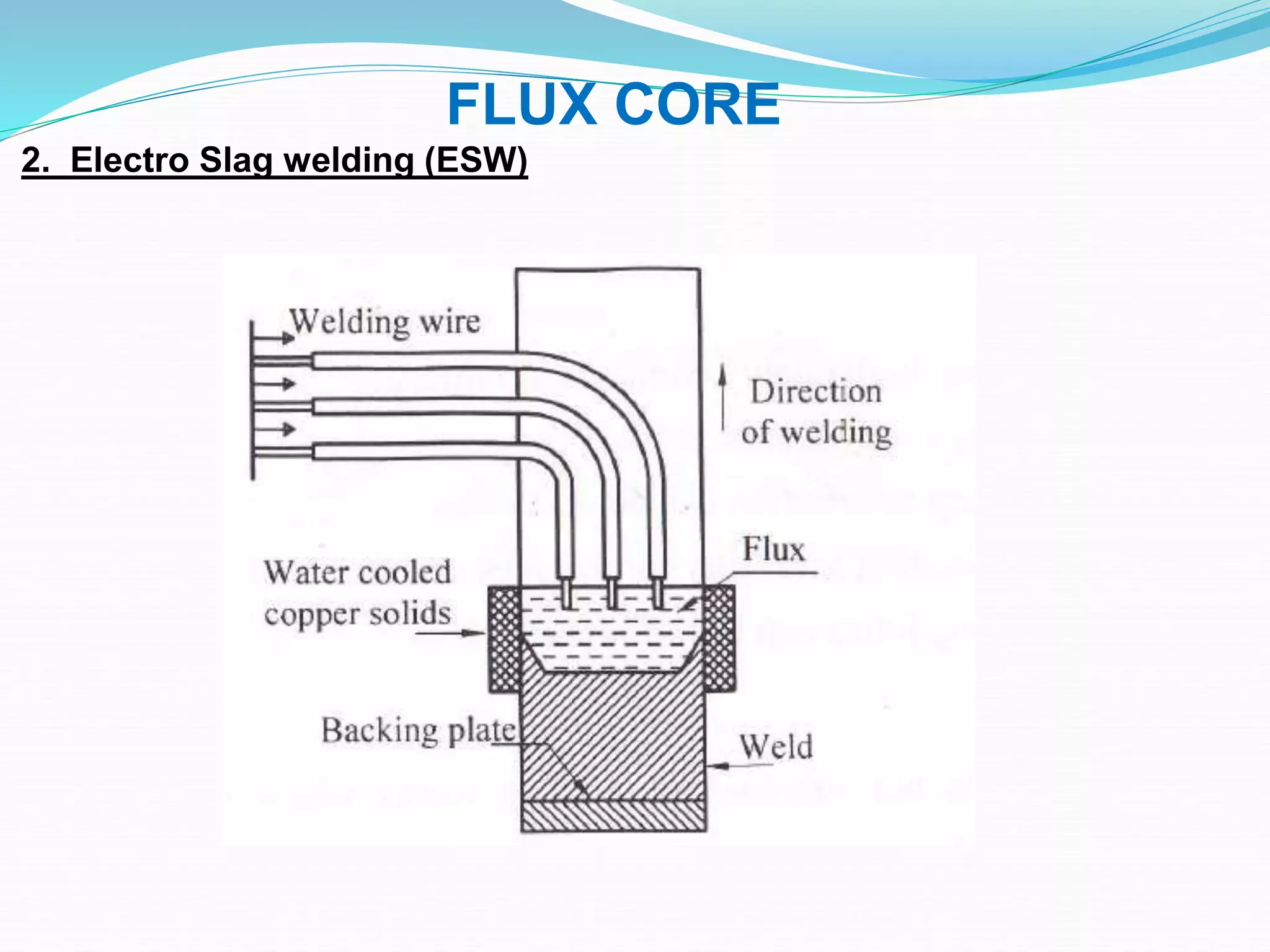

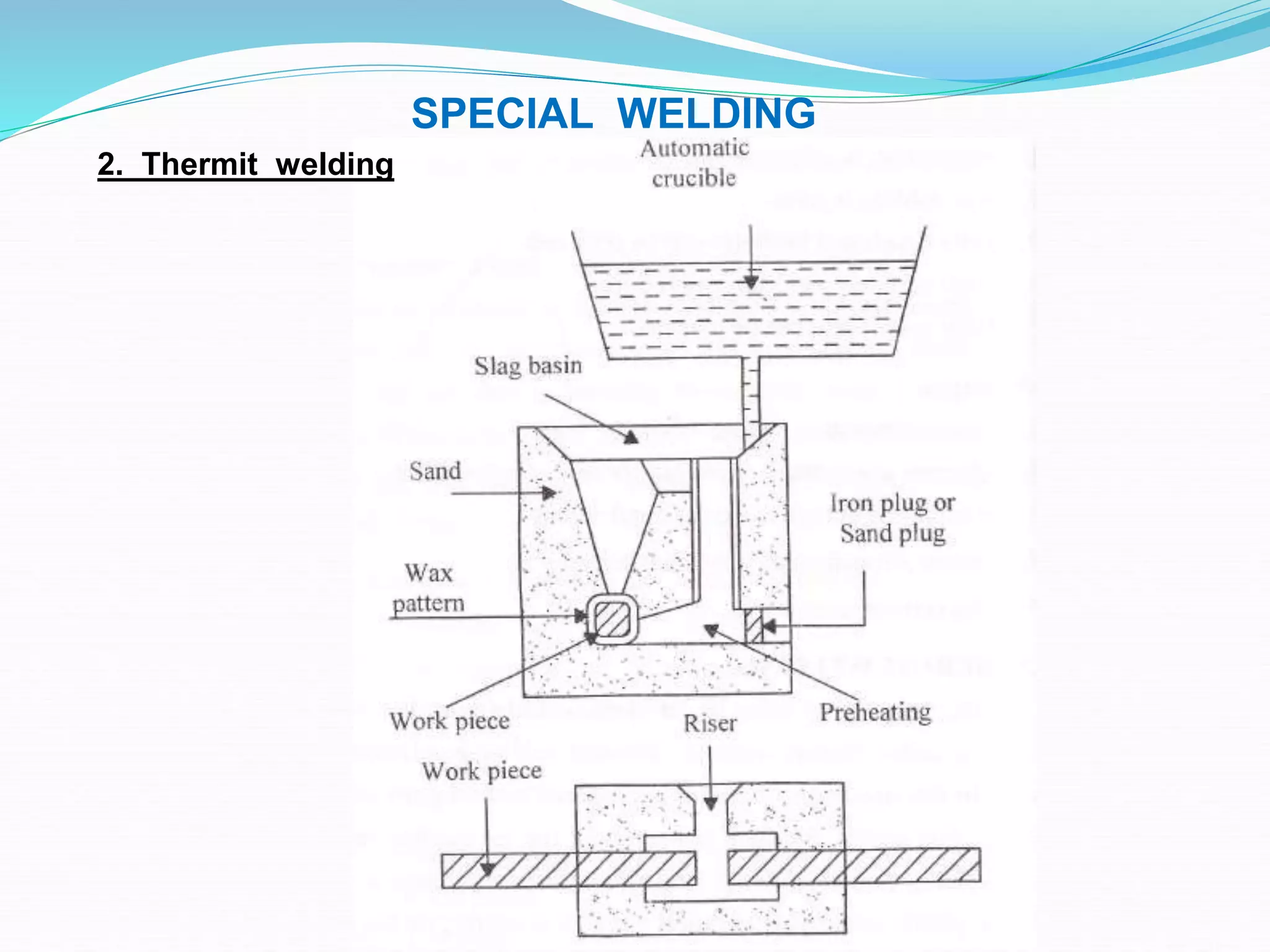

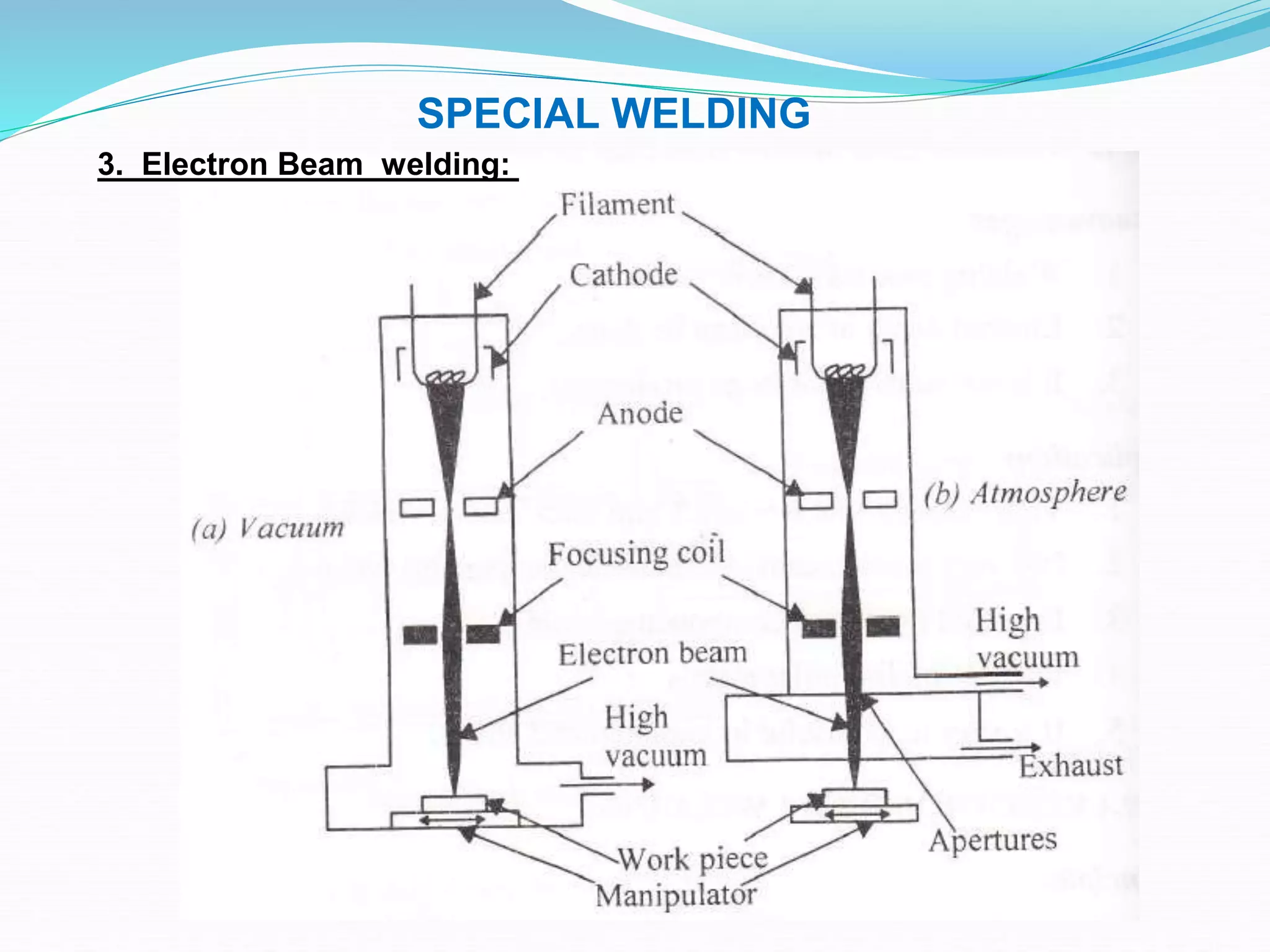

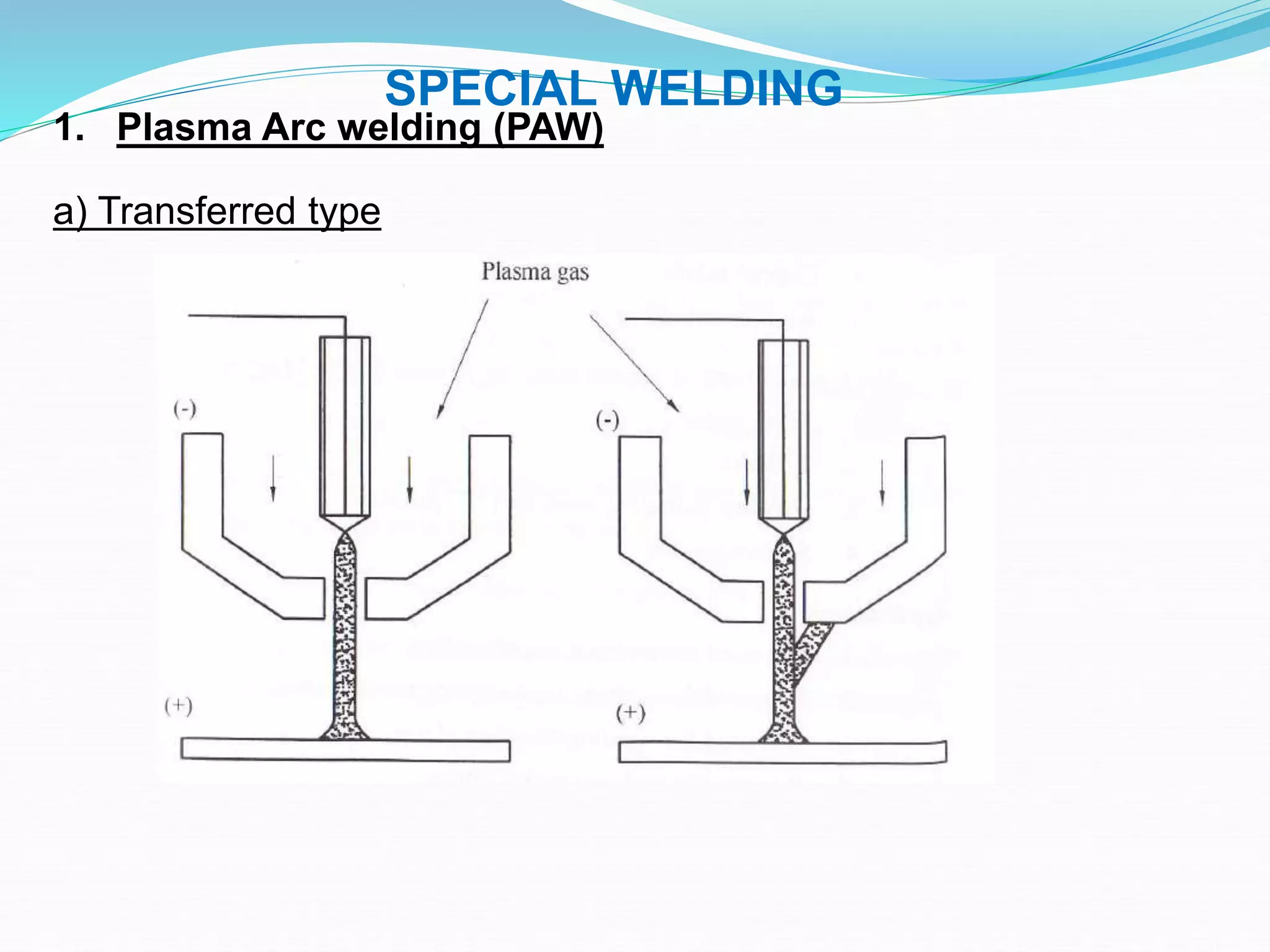

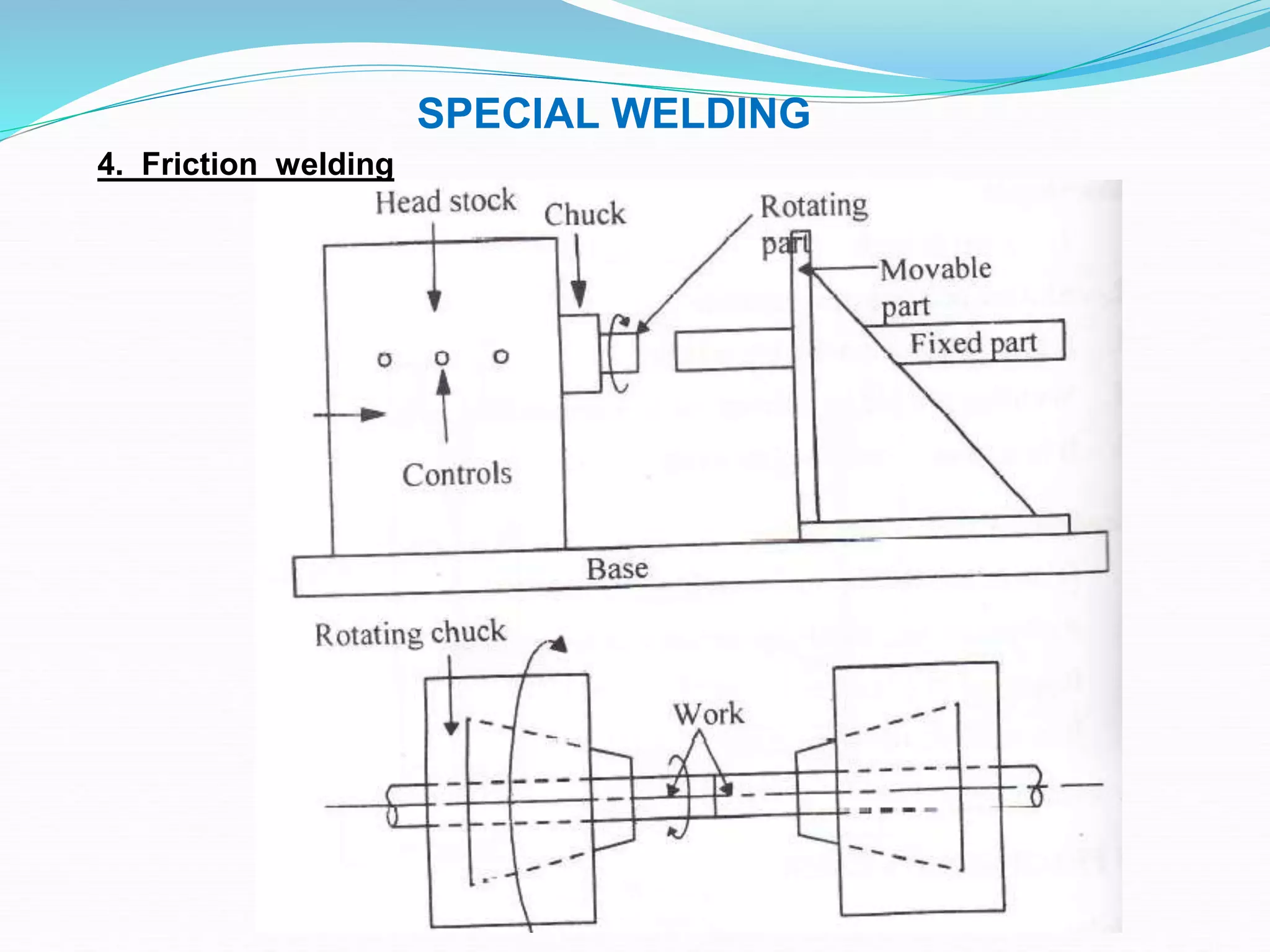

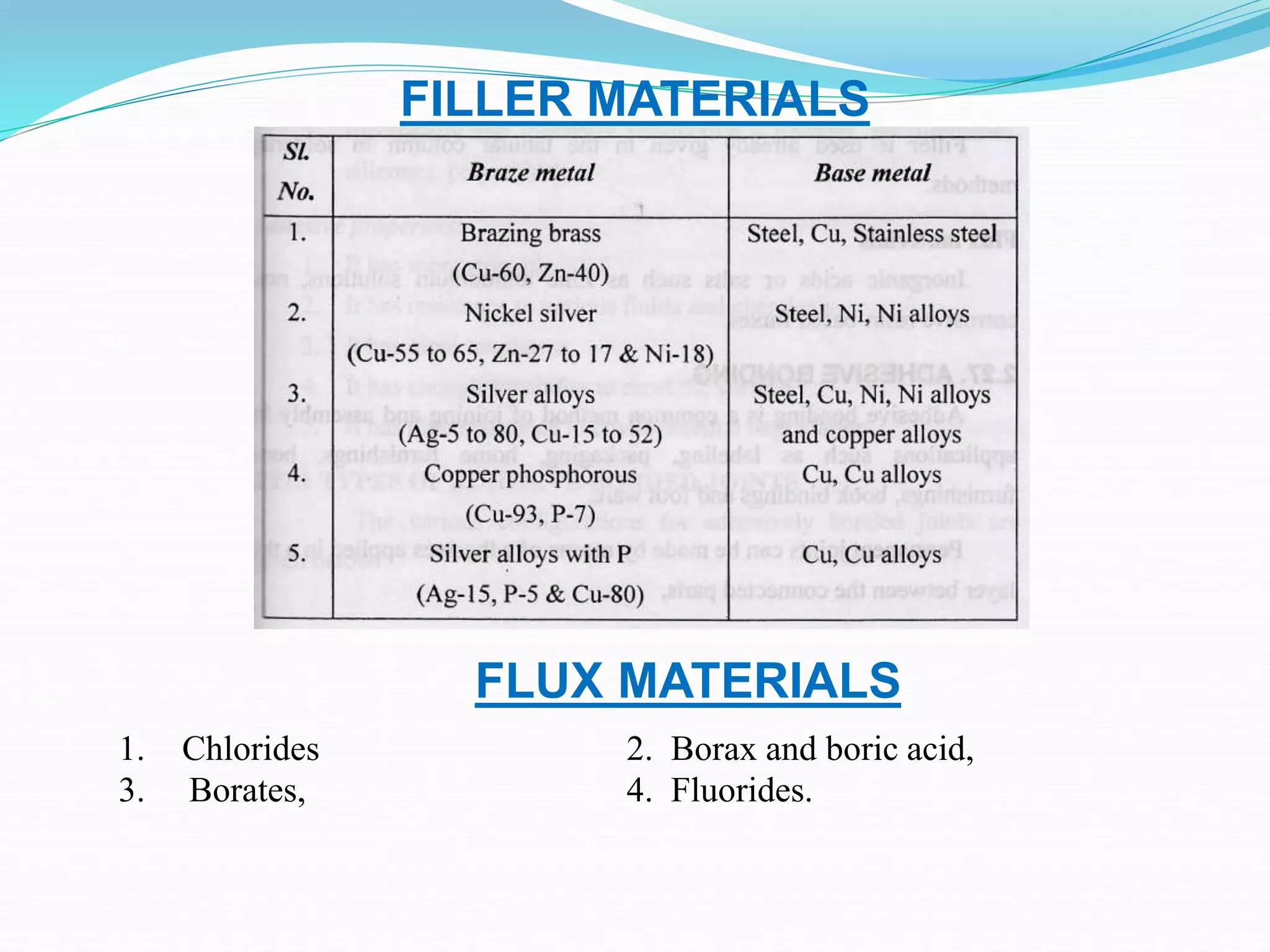

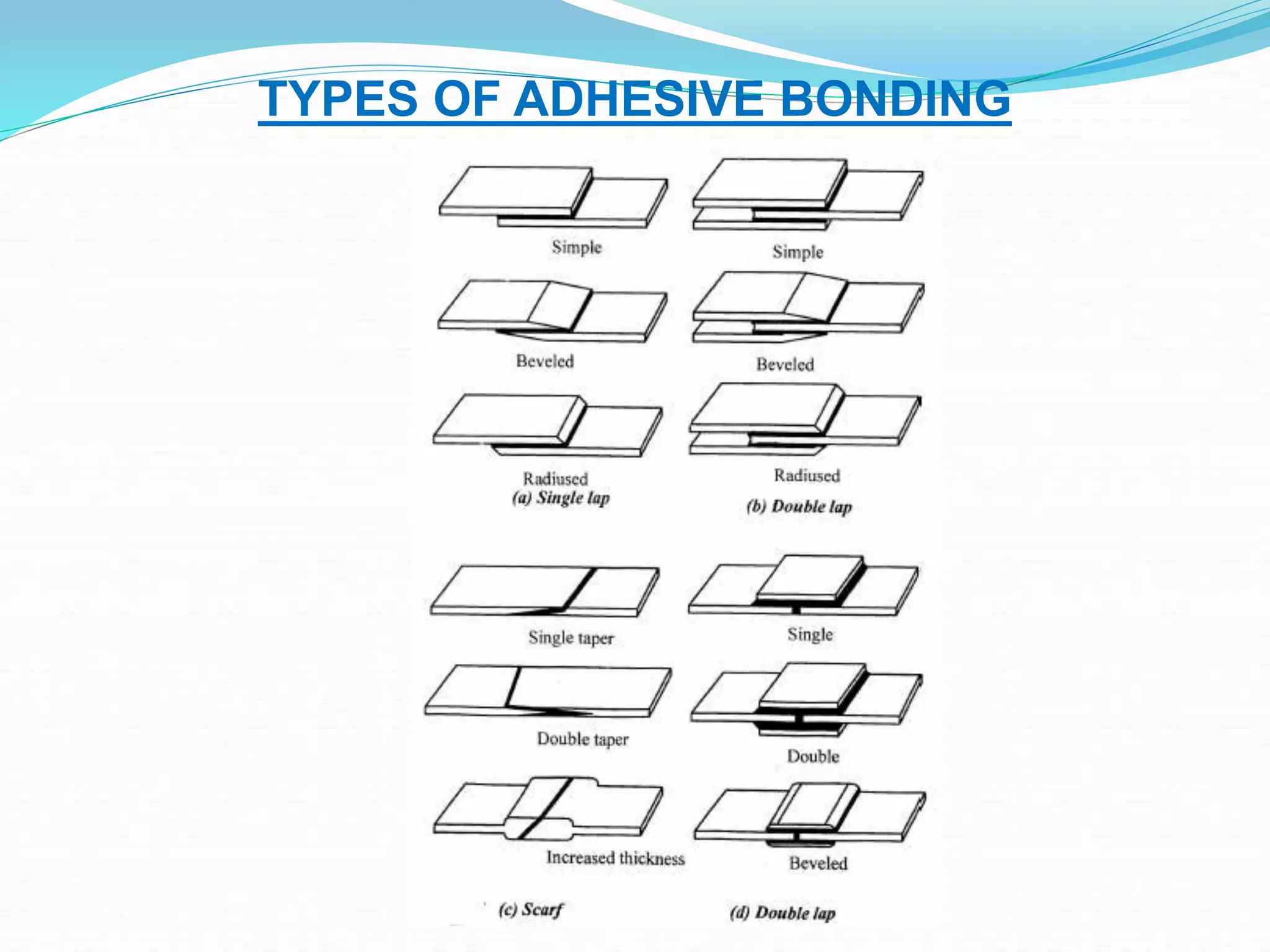

The document discusses various joining processes including welding, brazing and soldering. It describes different welding techniques such as gas welding, arc welding and various specialized welding processes. It also discusses resistance welding processes, filler materials, fluxes used and types of adhesive bonding.