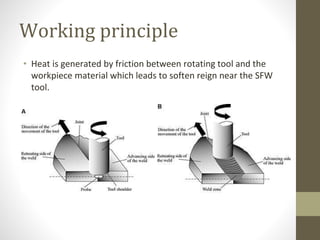

Friction stir welding (FSW) is a solid-state joining process invented in 1991 that uses a non-consumable tool to join materials without melting them, resulting in high-strength welds at lower costs. The process generates heat through friction, allowing the workpieces to be softened below their melting point, and offers advantages such as reduced distortion and improved mechanical properties, while having some disadvantages like slower traverse rates. FSW is widely used in industries such as shipbuilding, aerospace, and automotive for various applications.