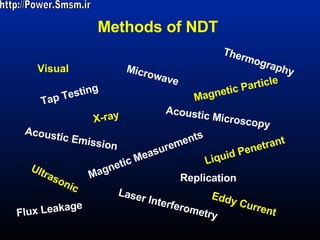

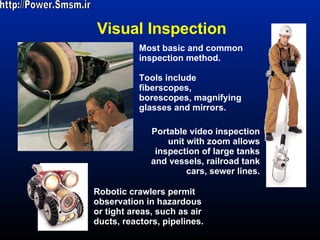

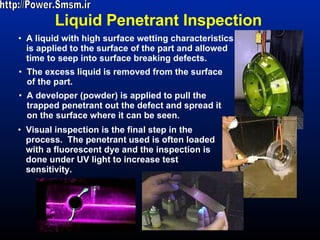

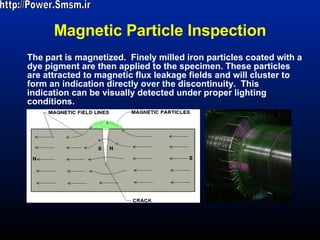

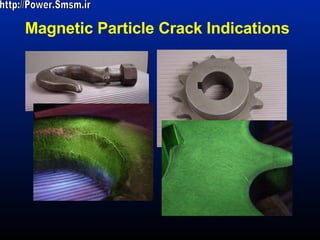

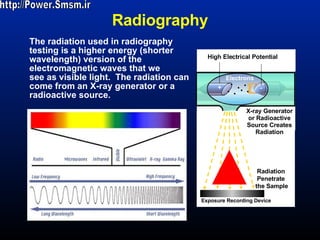

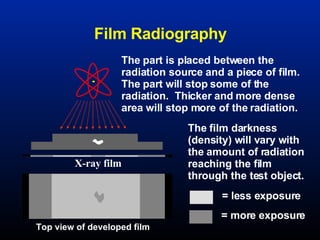

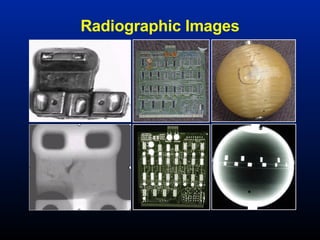

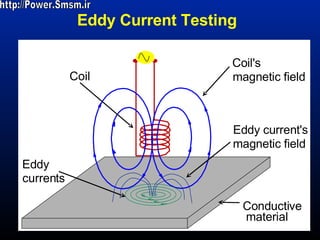

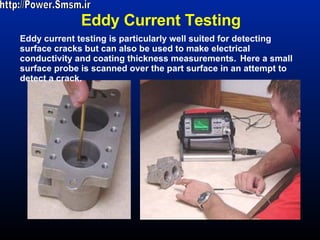

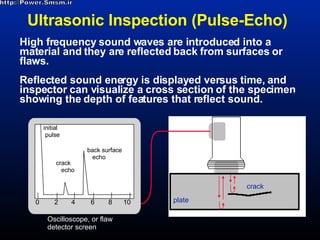

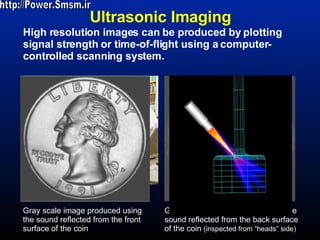

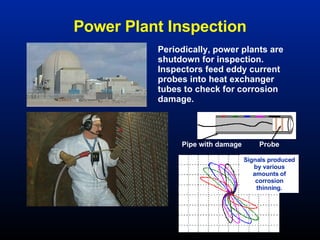

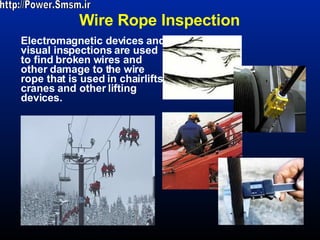

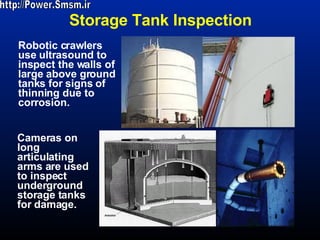

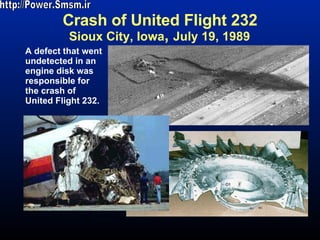

This document provides an introduction to nondestructive testing (NDT) methods. It defines NDT as using noninvasive techniques to determine the integrity of a material or structure without causing damage. The six most common NDT methods are described as visual inspection, liquid penetrant testing, magnetic particle testing, eddy current testing, ultrasonic testing, and radiography. NDT is used across many industries to inspect materials and components during production and in-service to detect flaws and ensure safety and reliability.