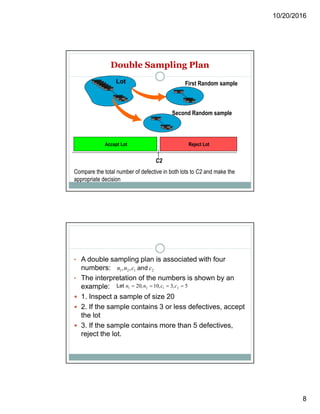

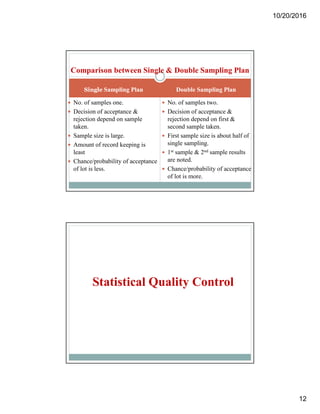

Acceptance sampling is a statistical method used to accept or reject product lots based on random sampling, primarily aimed at evaluating the quality level rather than improving it. Various sampling plans—single, double, and multiple—are employed depending on the situation, each with its advantages and disadvantages, including costs and risks of rejecting good lots or accepting bad ones. The document also discusses statistical quality control concepts, variations, and the use of control charts to monitor and improve processes.