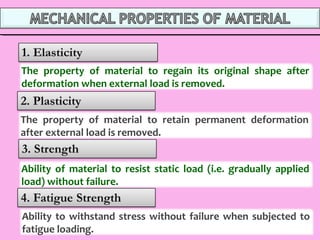

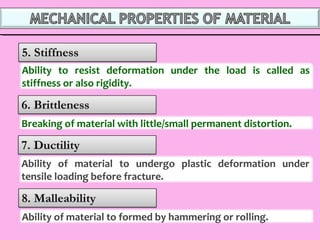

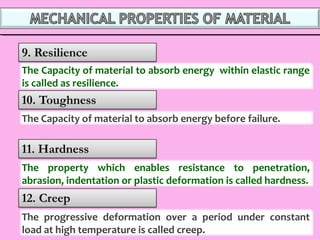

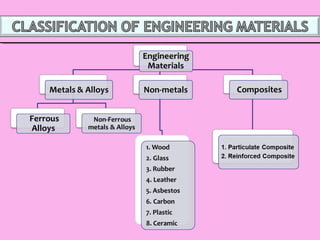

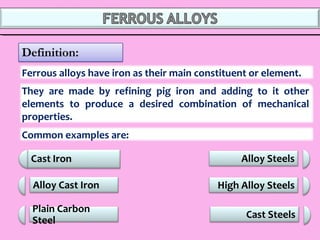

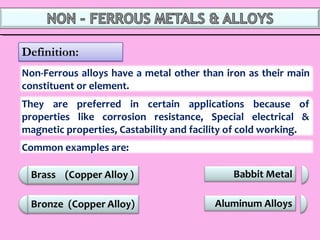

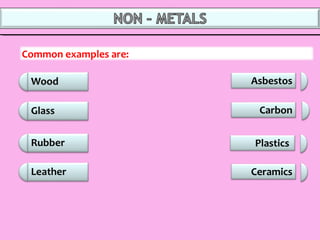

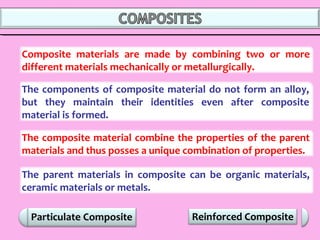

This document discusses various properties and types of engineering materials. It defines properties such as ductility, elasticity, toughness, hardness, creep, and resilience. It describes ferrous alloys which contain iron as the main element and lists examples. It also describes non-ferrous alloys which do not contain iron as the main element and provides examples. The document discusses composite materials which are made by combining two or more materials and retain their identities. It provides guidelines for selecting materials based on cost, availability, properties for the application, and suitability for manufacturing processes.