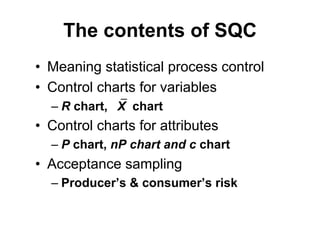

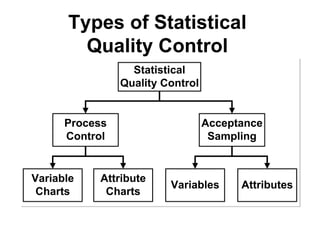

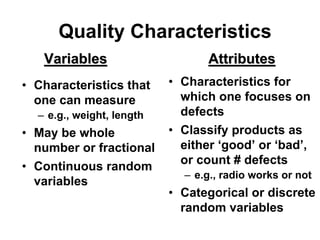

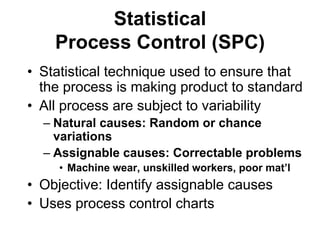

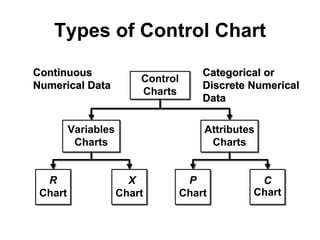

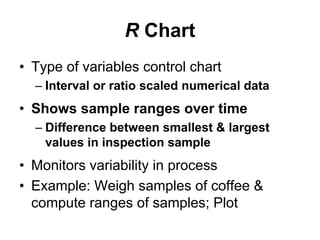

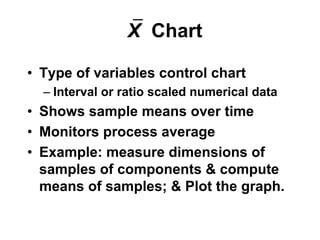

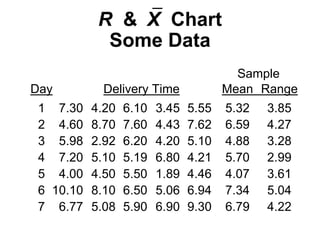

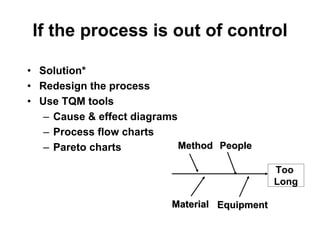

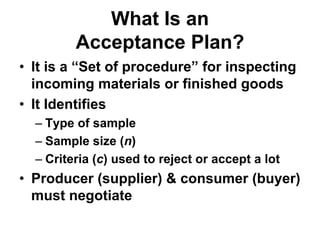

This document provides an overview of statistical quality control (SQC). It discusses key aspects of SQC including statistical process control using control charts for variables (X-bar and R charts) and attributes (P, NP, and C charts). It also covers acceptance sampling, which uses sampling plans to determine whether to accept or reject lots based on inspection results. The goal of SQC is to regulate product quality by monitoring processes and inspecting finished goods using statistical techniques.