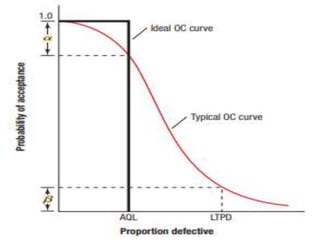

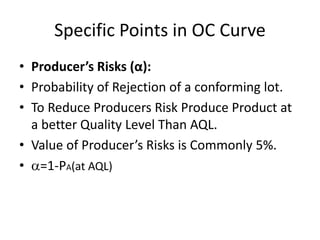

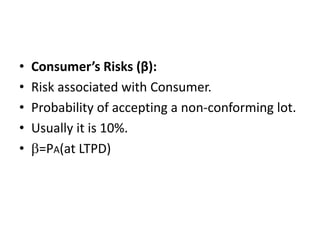

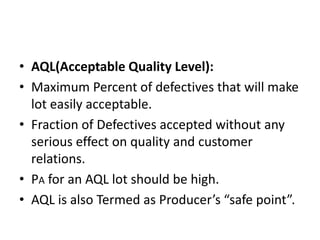

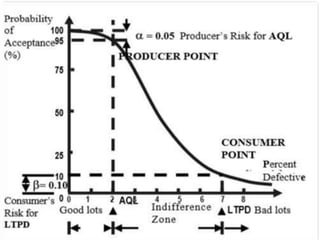

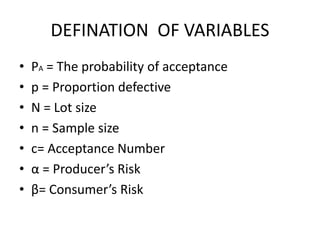

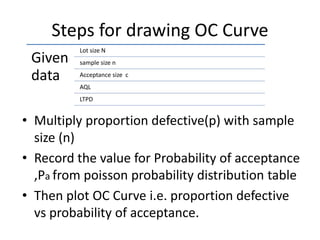

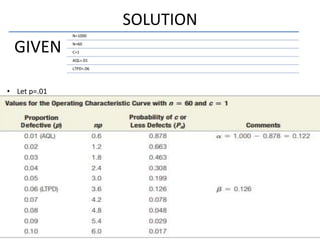

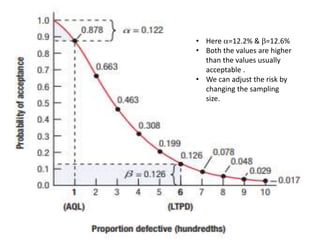

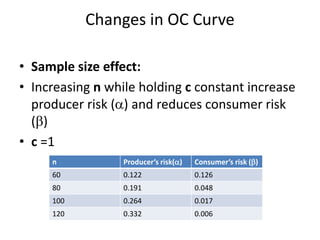

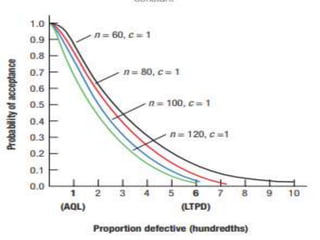

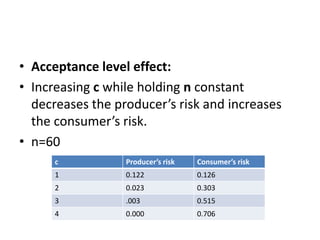

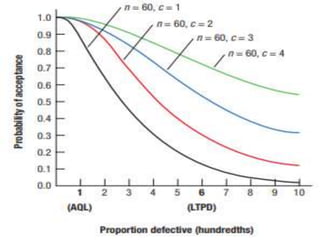

The document discusses operating characteristic (OC) curves, which are used in quality control to determine the probability of accepting production lots based on sampling inspections. An ideal OC curve would show 100% probability of acceptance for lots with defects below the acceptable quality level (AQL) and 0% above the AQL. Typical OC curves have an S-shape, plotting the probability of acceptance versus the fraction of defects. The curve shows the producer's risk of rejecting conforming lots and consumer's risk of accepting non-conforming lots. OC curves can be adjusted by changing the sample size or acceptance number to balance these risks.