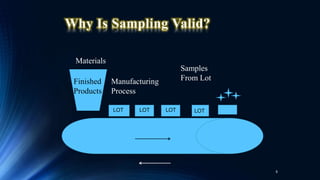

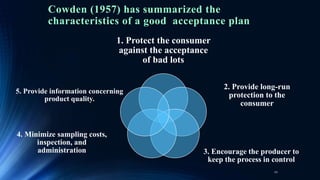

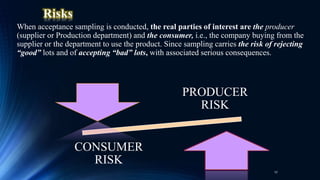

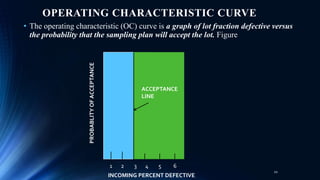

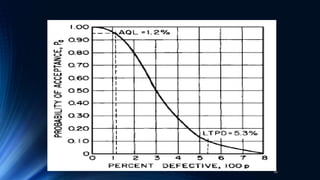

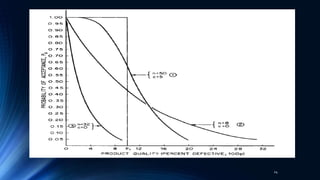

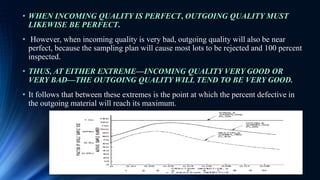

The document outlines an inspection and test sampling plan focused on acceptance sampling, detailing its advantages for quality control, such as cost efficiency and reduced inspector workload. It discusses the types of sampling, data types, and the associated risks for both producers and consumers, alongside the definitions of relevant terminology. Additionally, it elaborates on the operating characteristic curve, average sample number, and average outgoing quality limit, emphasizing the balance between inspection methods and quality assurance.