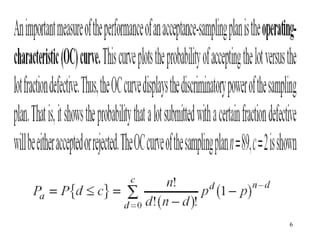

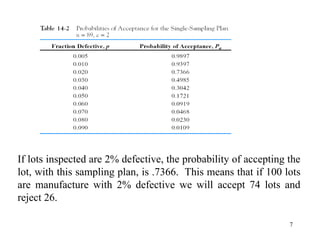

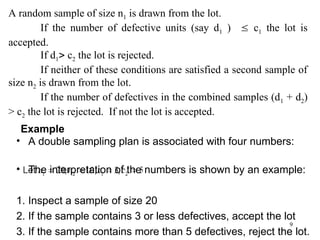

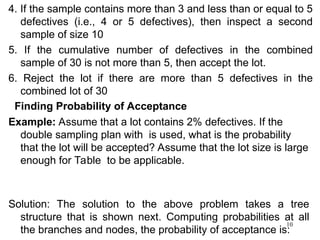

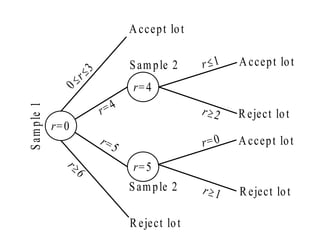

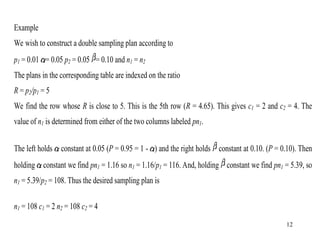

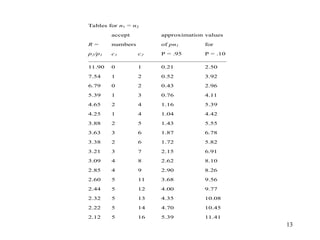

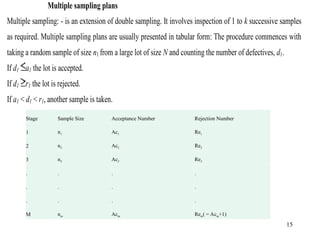

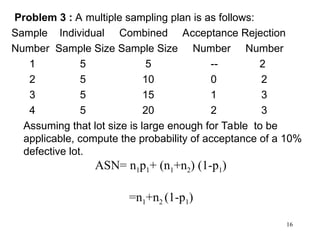

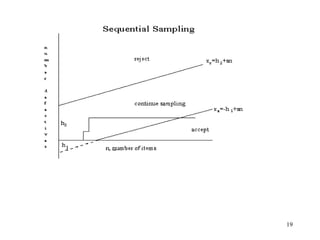

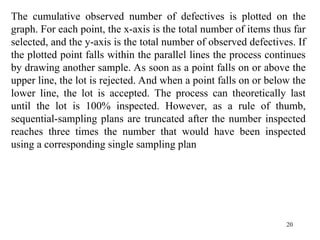

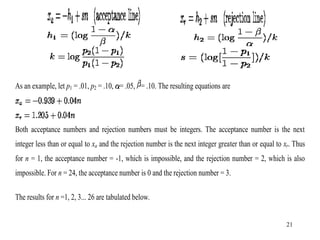

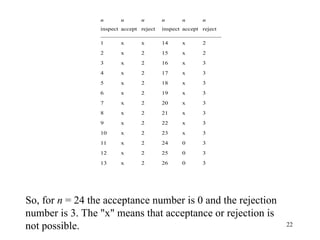

The document provides an overview of acceptance sampling methods, which are used to accept or reject products based on random samples rather than estimating lot quality. It details various sampling plans including single, double, and multiple plans, explaining their construction, advantages, and associated probabilities of acceptance. Acceptance sampling serves as an auditing tool to help ensure quality but may sometimes lead to the acceptance of defective lots or rejection of good ones.