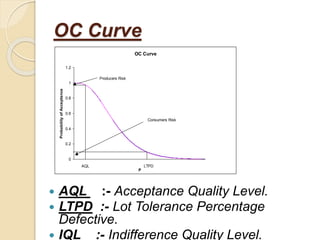

Acceptance sampling is a quality control method used to accept or reject product batches based on random samples rather than testing every individual product. It allows companies to assess quality levels with statistical certainty without inspecting full batches. Single sampling uses one sample while double sampling uses two to determine acceptance or rejection. Acceptance sampling aims to balance producers' risk of good products being rejected with consumers' risk of defective products passing inspection. Quality levels are defined by acceptance quality level, lot tolerance percentage defective, and indifference quality level curves.