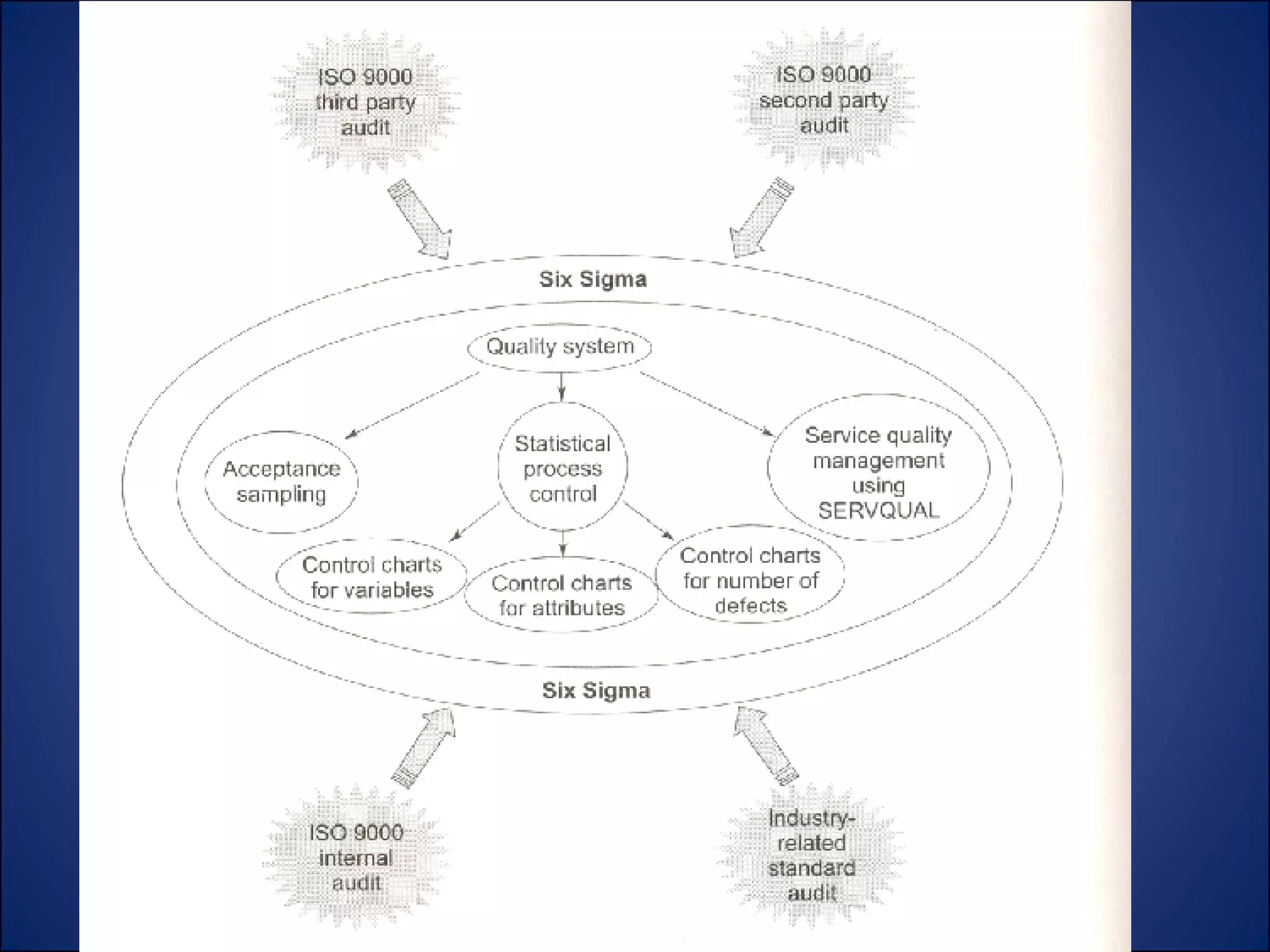

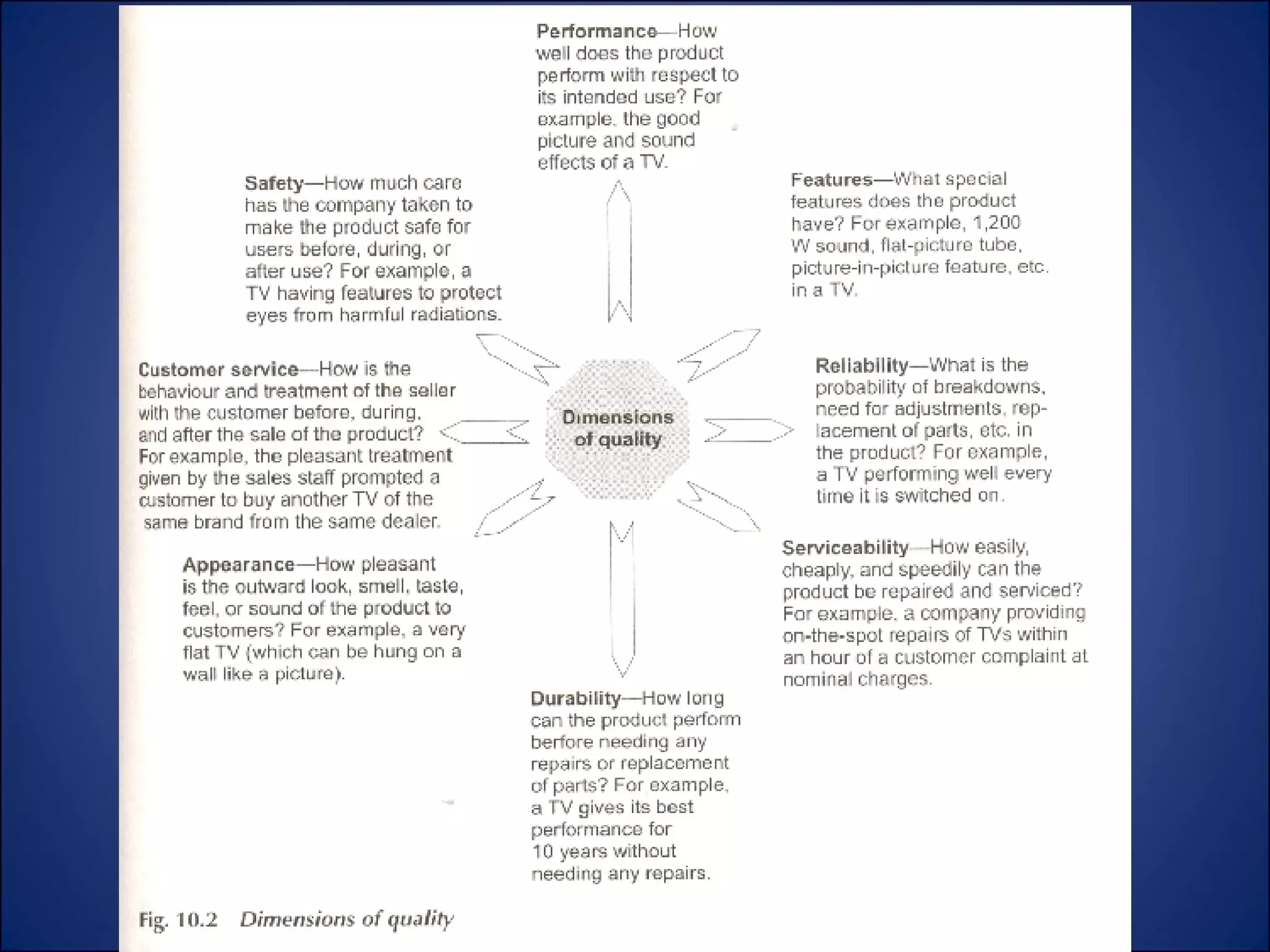

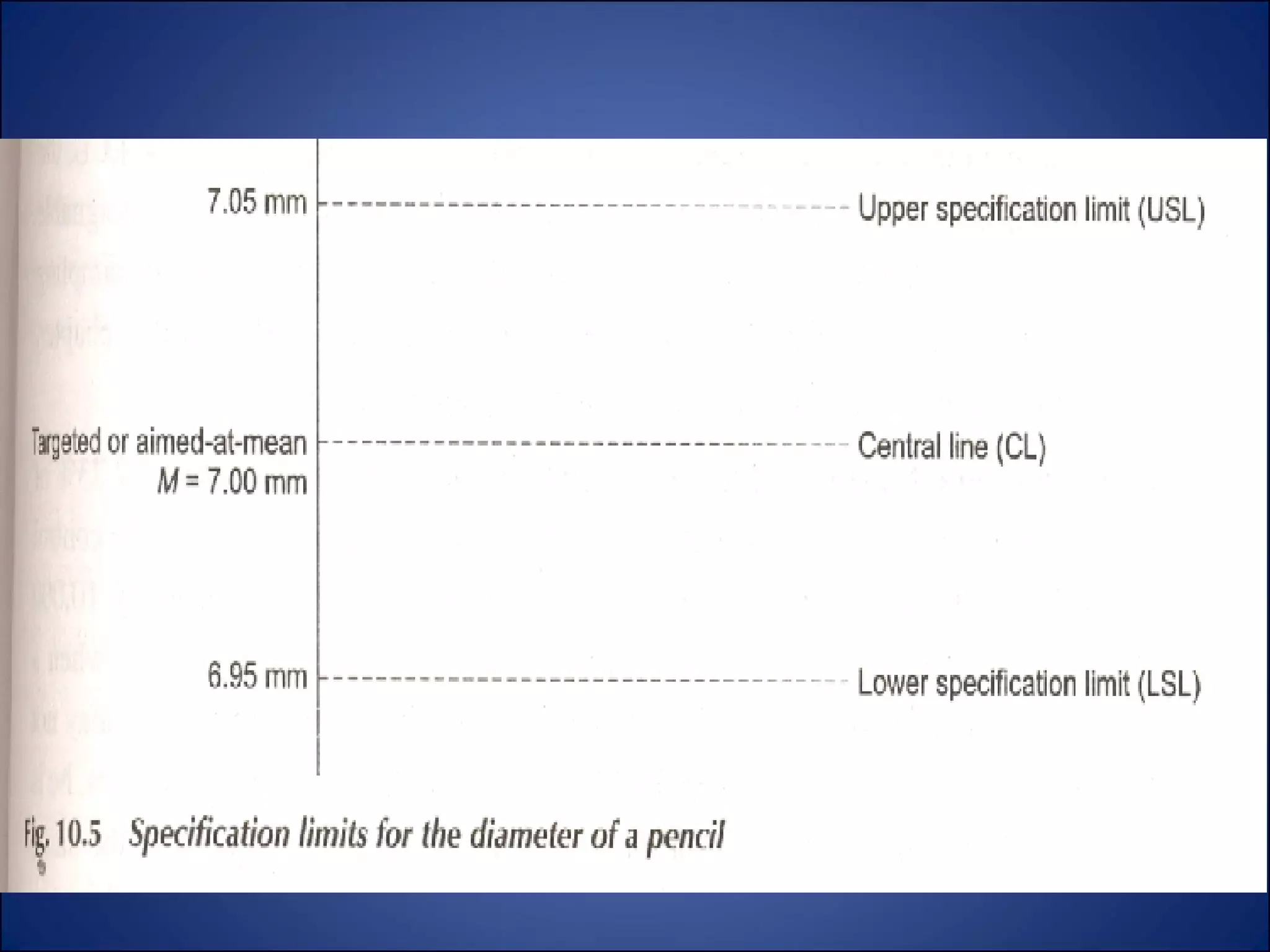

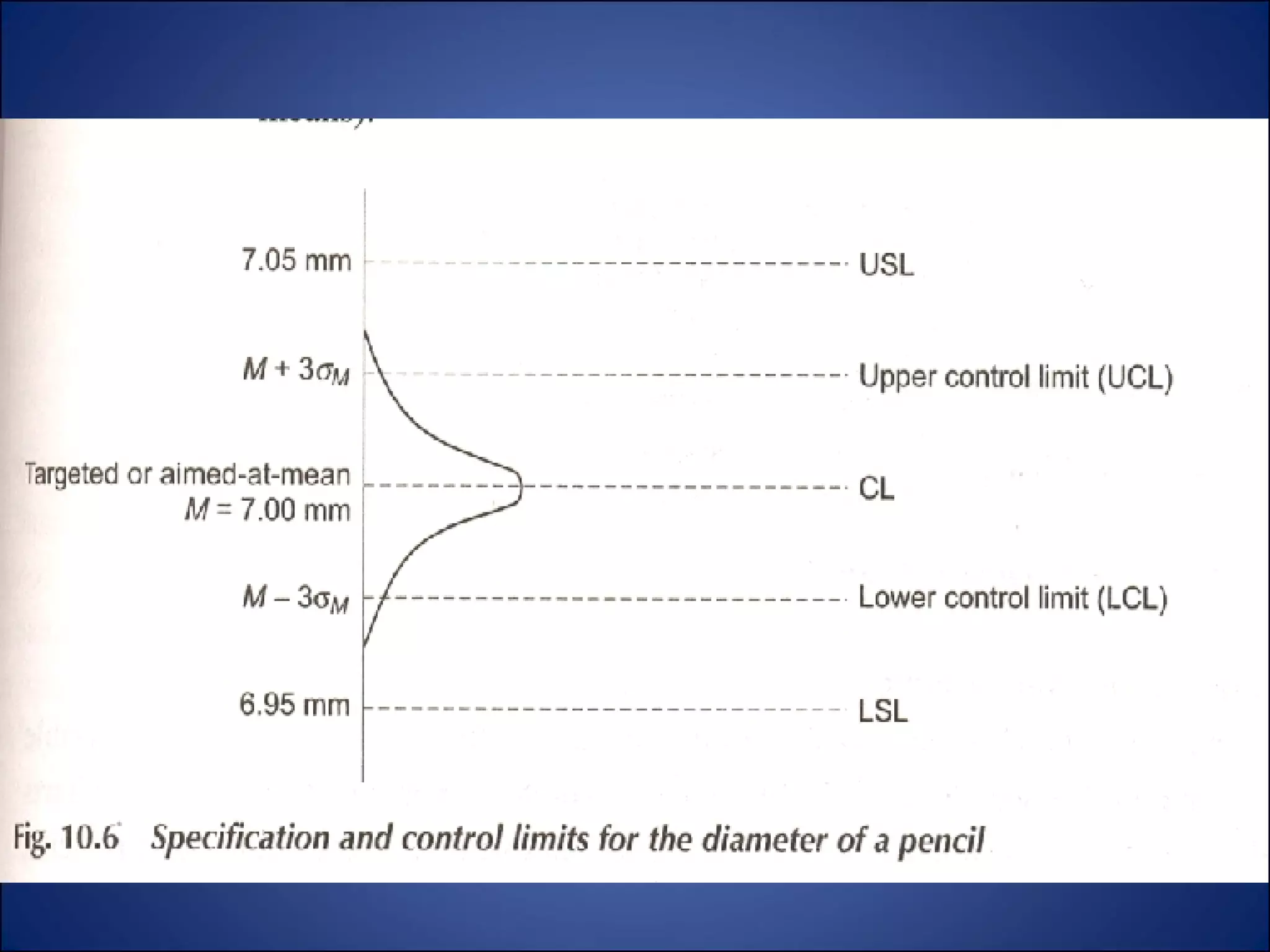

Quality refers to the characteristics of a product that satisfy customer needs. Quality control aims to ensure economical production of uniform, dependable products that meet customer expectations. It involves establishing quality standards and monitoring production to identify and address defects. Common quality control techniques include just-in-time production, quality at the source, inspection, statistical process control, quality circles, and total quality management. The overall goal is to prevent defects and continuously improve processes and customer satisfaction.