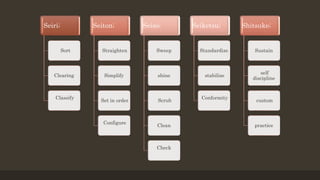

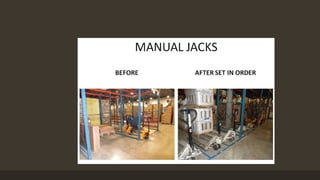

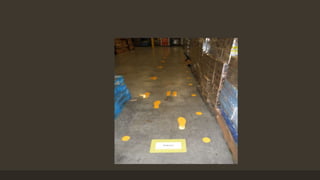

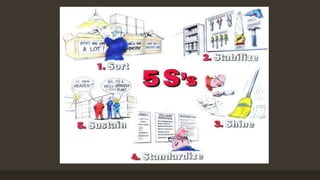

5s is a workplace organization methodology consisting of 5 Japanese words - Sorting, Straightening, Systematic Cleaning, Standardizing, and Sustaining. The steps involve sorting through items to eliminate unnecessary items, straightening and labeling storage areas, cleaning the workspace daily, standardizing processes between workstations, and sustaining the changes through self-discipline. Implementing 5s leads to benefits like improved efficiency, reduced waste, improved safety and quality, and increased worker commitment. The overall goals are increased productivity, safety, reduced waste, and worker commitment.