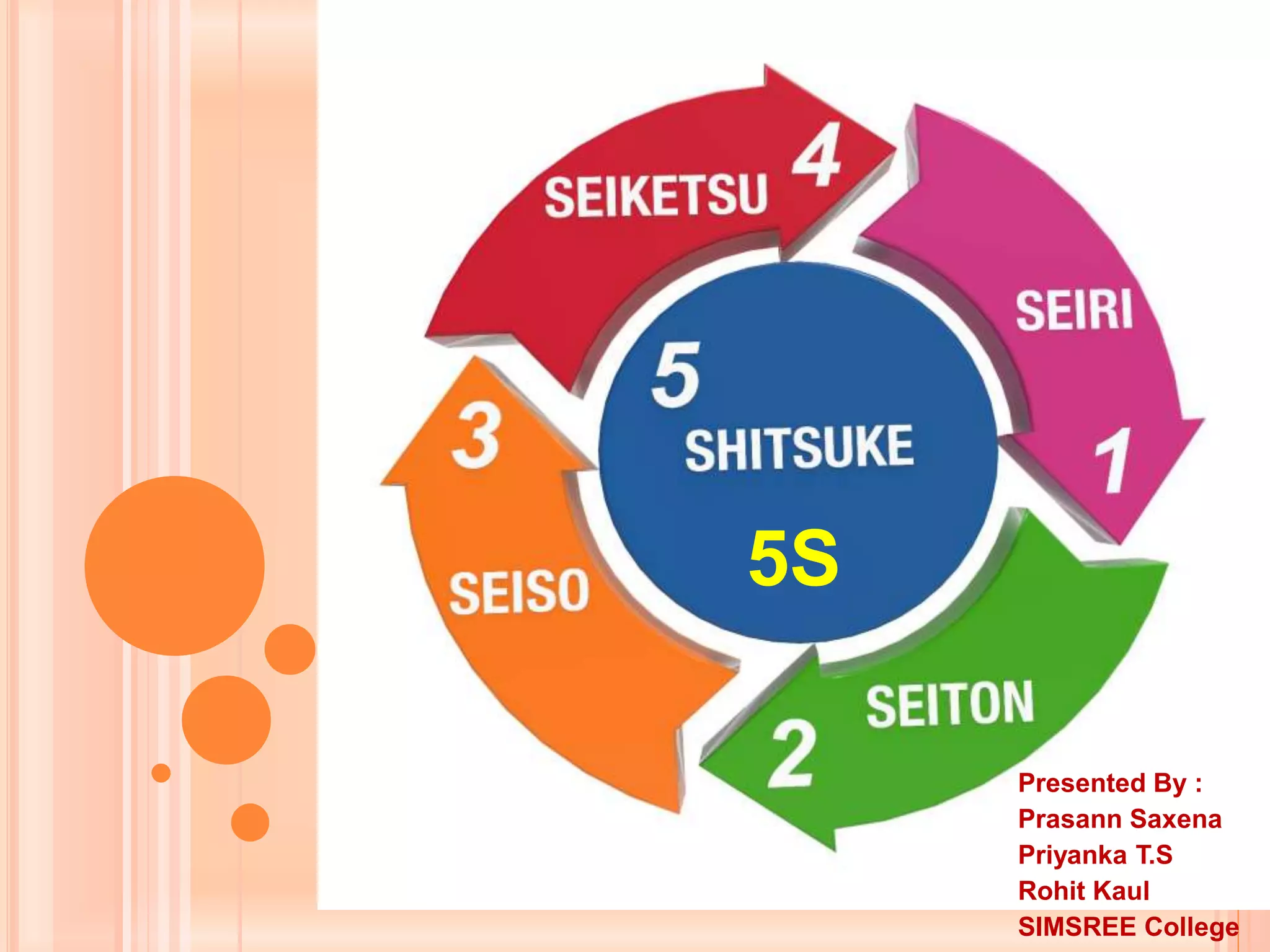

The document discusses the 5S methodology for organizing and maintaining a clean and efficient workplace. 5S stands for Sort, Straighten, Shine, Standardize, and Sustain. The document analyzes the application of 5S principles in a college canteen, noting both good and bad practices. Specifically, it finds that while the canteen effectively implements the first three S's, it struggles with Sustain due to lack of staff. Recommendations are provided to improve practices through additional staff, separate serving counters, checklists, and customer feedback. The overall 5S methodology is presented as an effective tool for lean manufacturing and a clean, orderly workplace.