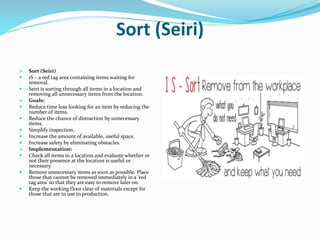

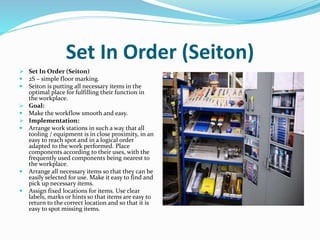

Lean is a set of practices that aim to improve efficiency by eliminating waste. The 5S methodology is a workplace organization technique that originated in Japan for manufacturing. It consists of five Japanese words that translate to Sort, Set In Order, Shine, Standardize, and Sustain. The steps involve sorting through all items and removing unnecessary ones, arranging necessary items optimally, cleaning and inspecting regularly, standardizing processes, and sustaining practices through self-discipline. 5S has expanded beyond manufacturing to industries like healthcare and knowledge work by applying the principles to information and media instead of physical products.