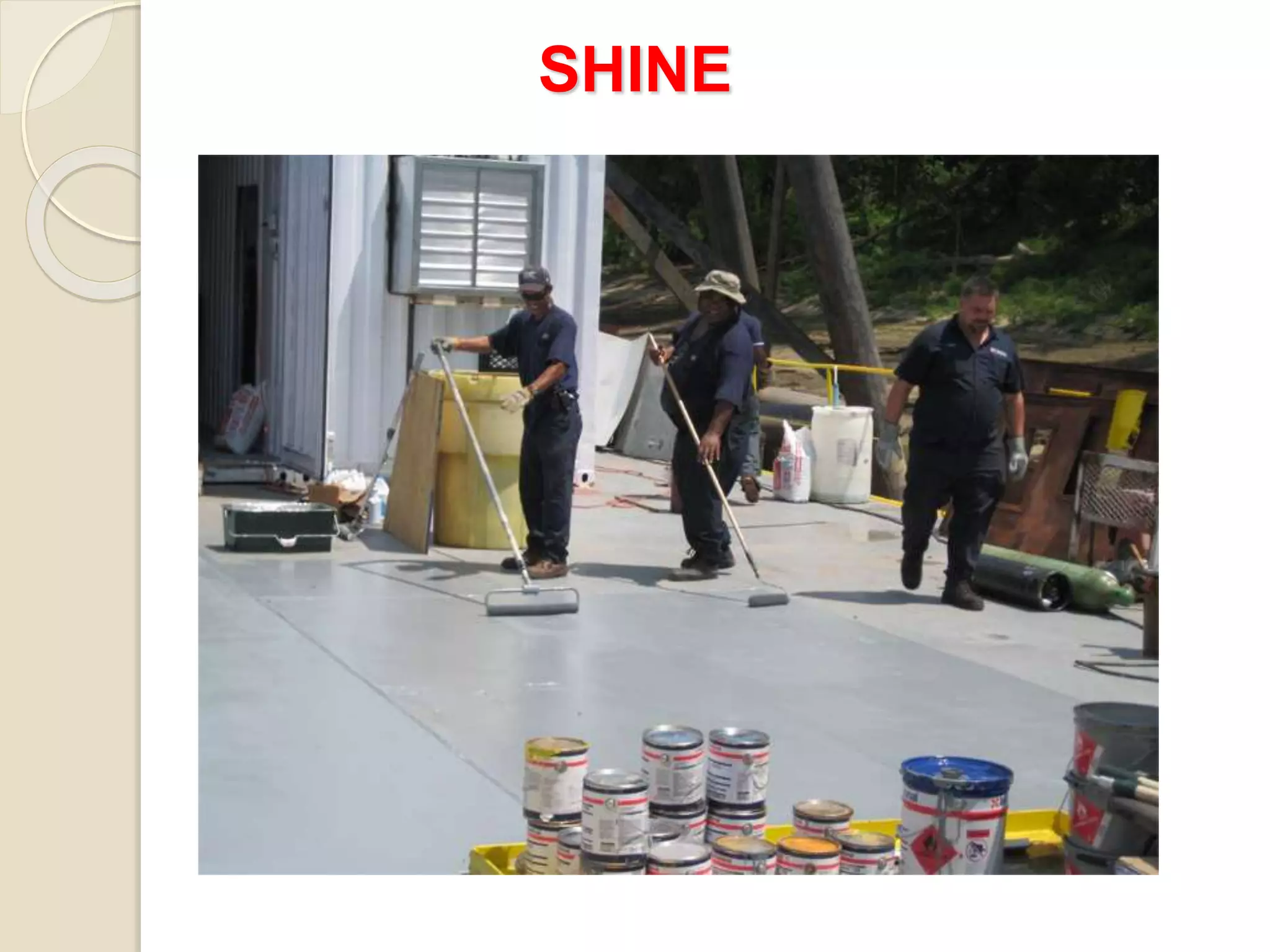

5S is a methodology for organizing and standardizing the workplace. It consists of five Japanese words that begin with "S": seiri (sort), seiton (set in order), seiso (shine), seiketsu (standardize), and shitsuke (sustain). The document defines each of the 5S steps and provides examples of how they are implemented to create an efficient, clean, and safe work environment through continual improvement. Proper implementation of 5S requires full participation from all employees and leads to benefits like improved productivity, quality, delivery, customer focus, and safety.