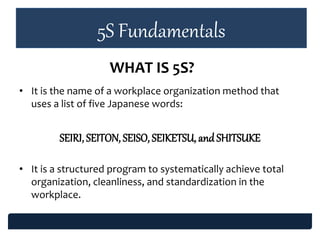

Here are the steps I would take to apply 5S in the computer laboratory:

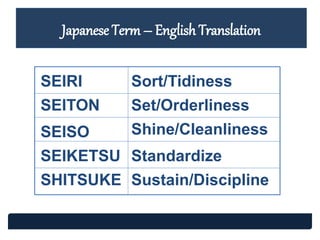

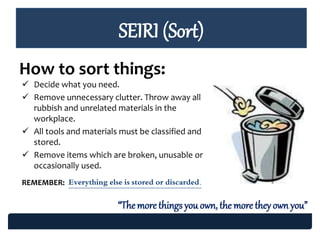

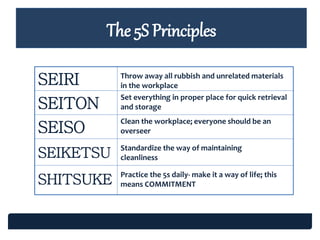

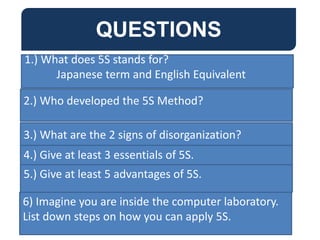

1. Sort (SEIRI): Remove all unnecessary and unrelated items from the lab. Throw away trash.

2. Set in order (SEITON): Arrange all tools, parts, manuals in designated areas for quick retrieval. Most used items in easy to access places.

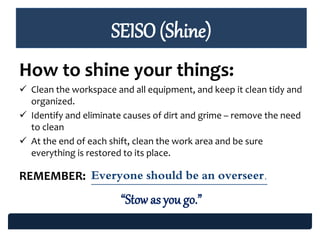

3. Shine (SEISO): Thoroughly clean and sanitize all surfaces, equipment and tools. Ensure everything is clean and tidy.

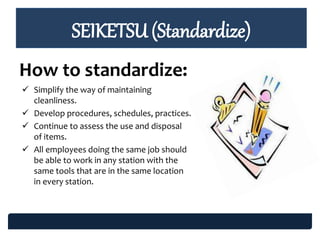

4. Standardize (SEIKETSU): Create procedures for cleaning, organizing and maintaining the lab. Develop schedules and assign responsibilities.

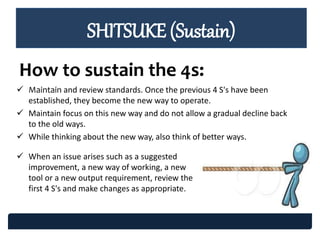

5. Sustain (SHITSUKE): Practice the new 5