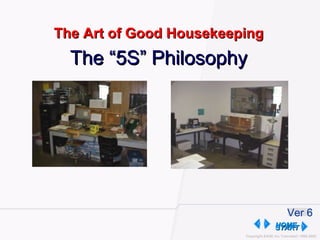

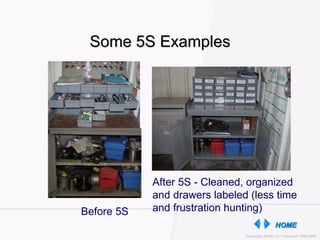

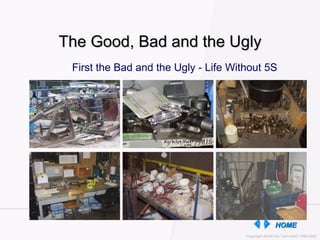

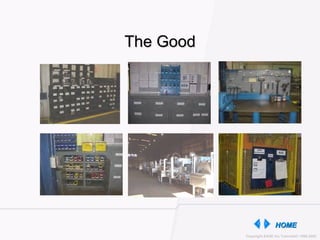

The 5S philosophy focuses on effective workplace organization and standardized work procedures based on Japanese words that begin with S. It simplifies the work environment, reduces waste and non-value activity while improving quality, efficiency and safety. The 5S process involves sorting to eliminate unnecessary items, setting items in order through efficient storage methods, shining through thorough cleaning, standardizing best practices, and sustaining the changes through continuous improvement efforts.