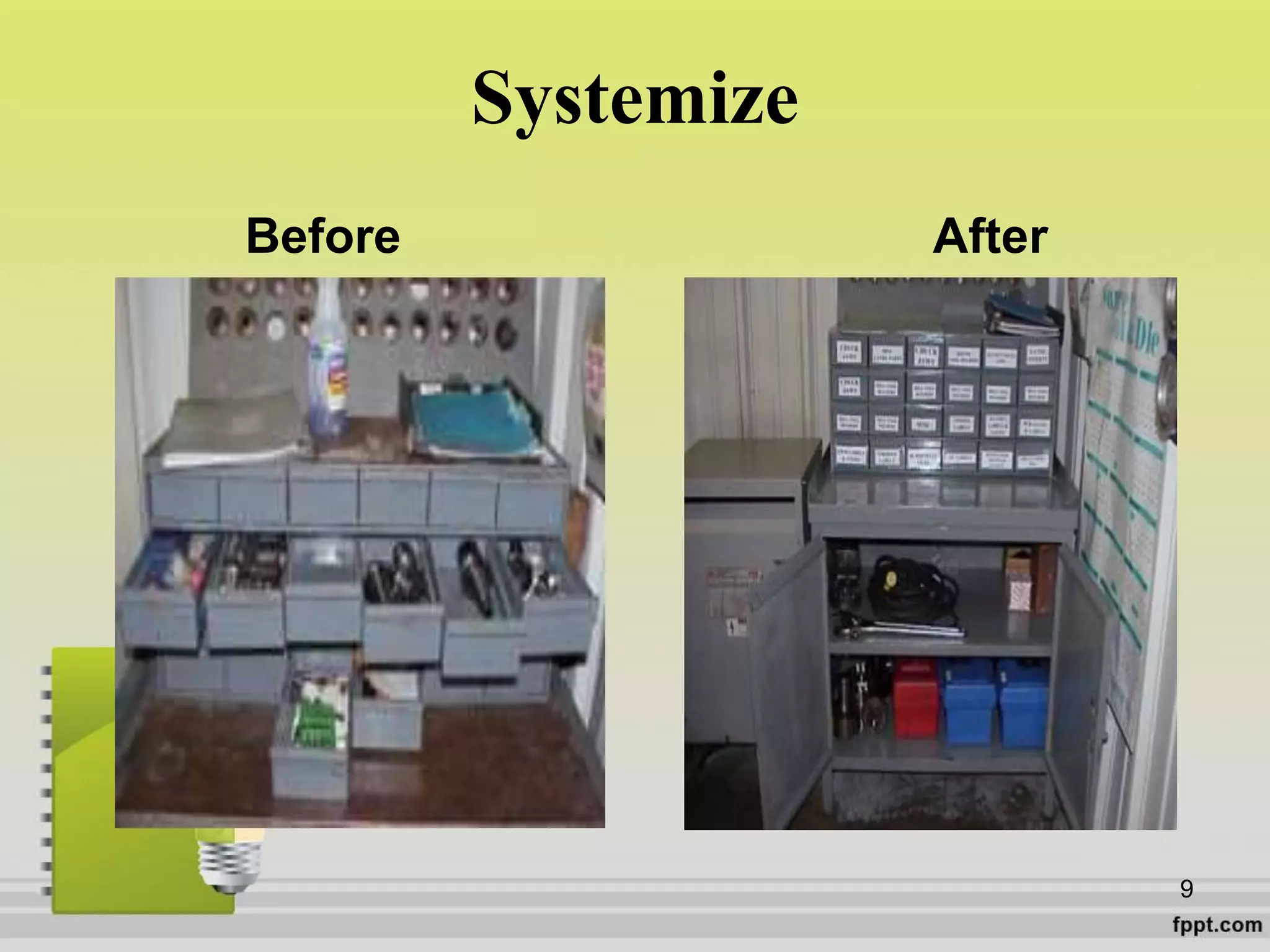

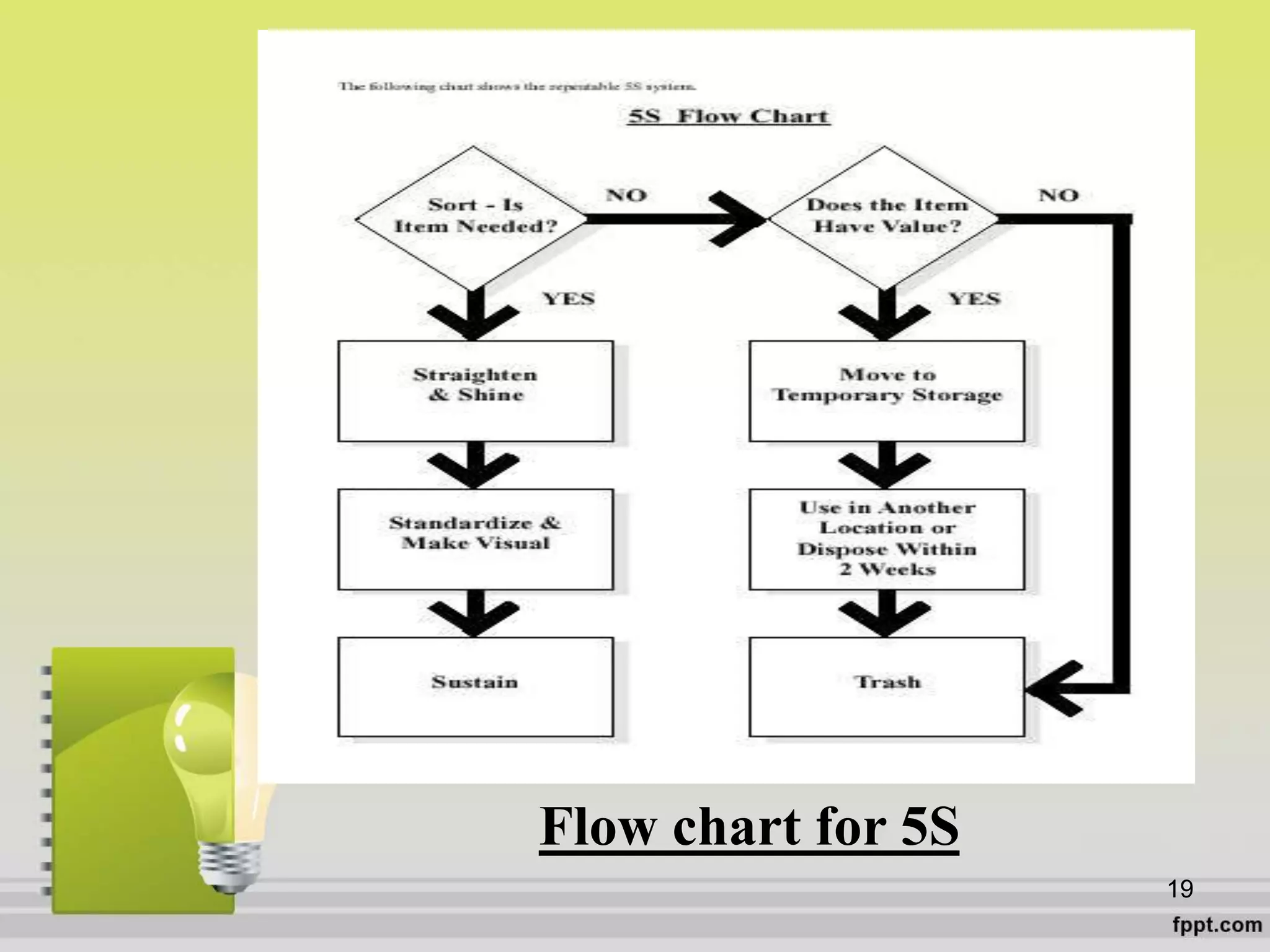

5S is a workplace organization methodology using five Japanese words: sorting, systematizing, sweeping, simplifying, and self-discipline. It aims to achieve high quality, safety, and productivity by providing a conducive work environment. The objectives are increased productivity, safety, reduced waste, and improved worker commitment. It involves sorting through items and keeping only essential tools, establishing places for everything, cleaning the workspace daily, standardizing work stations, and maintaining discipline to prevent backsliding. Benefits include improved efficiency, reduced waste, faster and better work, increased safety, and an attractive work environment.