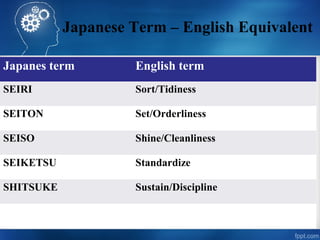

This document summarizes the 5S methodology, which is a workplace organization method using five Japanese words - Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. It provides definitions for each term and describes how to implement the steps of sorting, setting in order, shining, standardizing, and sustaining. Some key benefits of 5S include increased space, improved machine maintenance, higher productivity, reduced accidents, and a cleaner and more organized workplace. The presentation was delivered to Engineering student Arbab Shahid by Umar Farooq from the Mechanical Engineering department at M.N.S UET Multan.