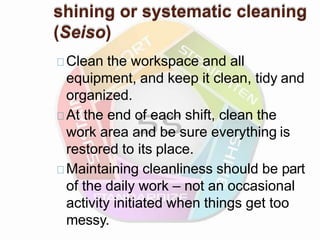

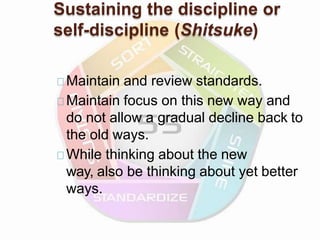

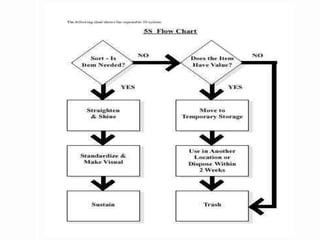

5S is a workplace organization methodology derived from five Japanese words focusing on sorting, straightening, systematic cleaning, standardizing, and sustaining. It aims to improve organizational efficiency, reduce waste, enhance safety, and create a visually appealing environment. The practice, widely adopted in Japan, is recognized for its contributions to quality and productivity in the workplace.