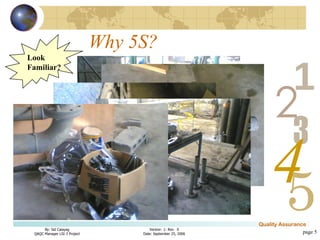

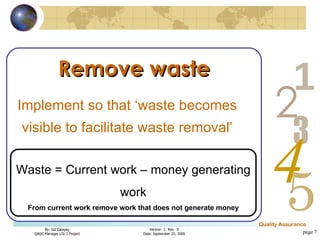

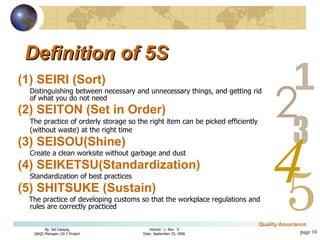

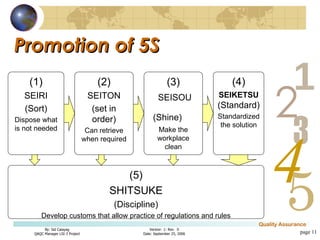

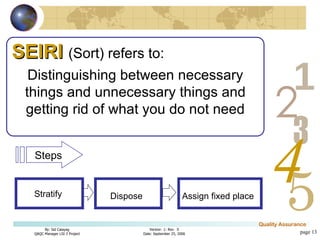

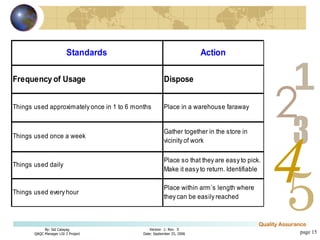

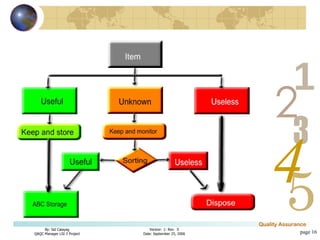

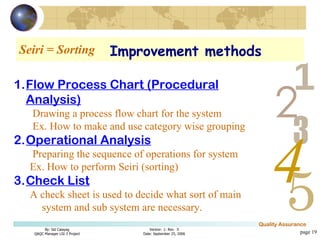

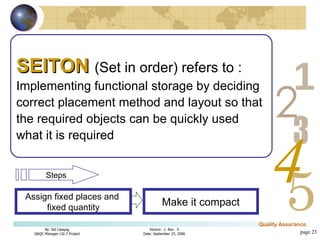

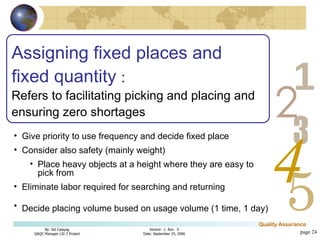

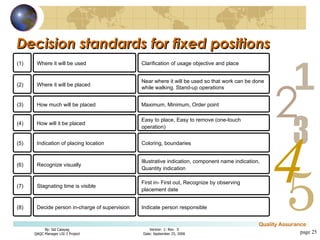

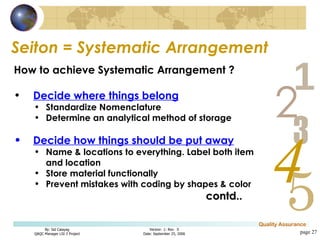

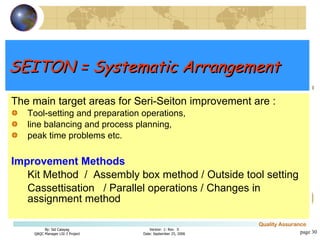

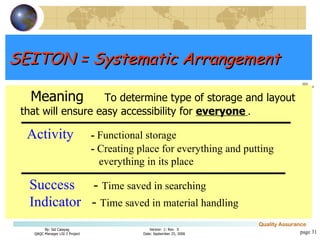

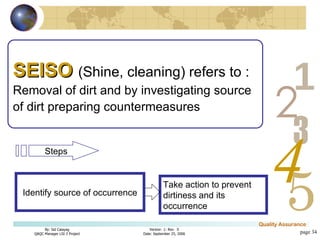

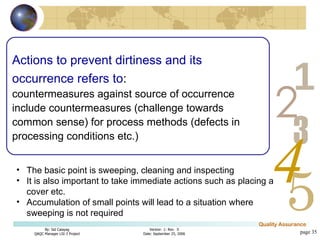

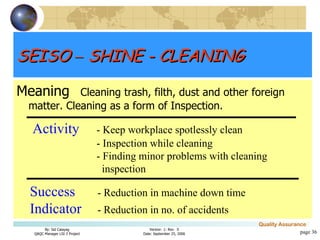

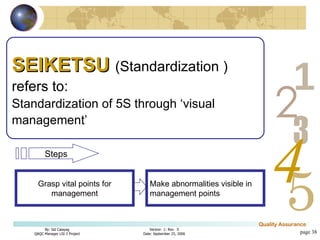

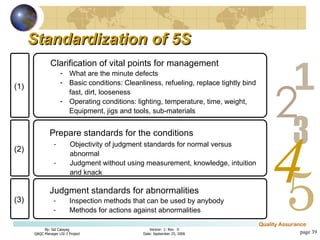

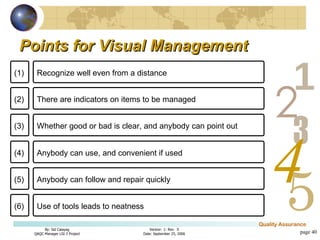

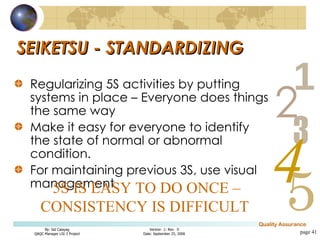

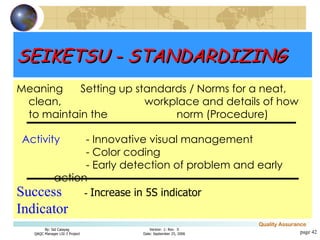

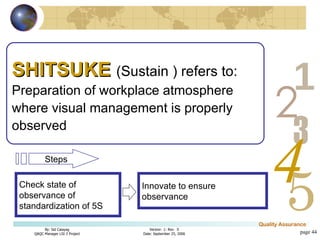

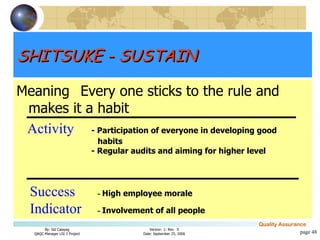

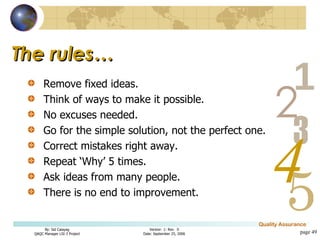

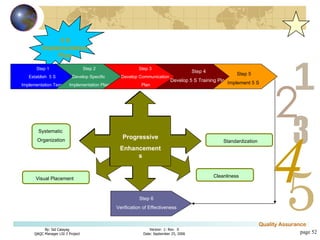

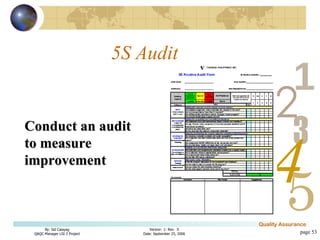

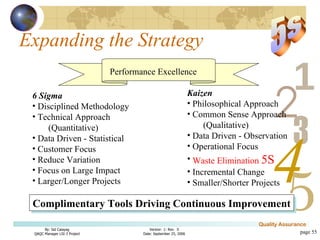

The document outlines the 5S methodology, which is a program used to improve project performance through workplace organization and standardization. It describes the five steps of 5S - Sort, Set In Order, Shine, Standardize, and Sustain. For each step, it provides definitions, examples of activities that can be done, and how success can be measured. The overall goal of 5S is to enhance work efficiency, reduce costs, eliminate waste, and improve productivity and work ethics through an organized, standardized workplace.