1.6. TQM Frame work.pdf

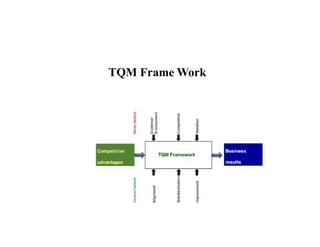

- 4. • It begins with the knowledge provided by quality gurus– • Shewhart, Deming, Juran, Figenbaum, Ishikawa, Crosby and Taguchi • They contributed to the development of principles and practices and/or the tools and techniques. • Some of these tools and techniques are used in the product and/or service realization activity. • Feedback from internal/external customers or interested parties provides information to continually improve an organization’s system, product and/or service

- 5. quality guru A guru, by definition, is a good person, a wise person and a teacher. A quality guru should be all of these, plus have a concept and approach to quality within business that has made a major and lasting impact. The field of quality management has evolved significantly over the past several decades, thanks to the contributions of many quality gurus who have shaped and influenced the field. These individuals have developed and introduced new ideas, theories, and methods that have helped organizations improve their performance and achieve their goals. These gurus have done, and continue to do, that, in some cases, even after their death.

- 6. W. Edward Deming One of the pioneers of quality management, Deming is known for his work in Japan after World War II, where he helped Japanese companies improve their quality and productivity. He is best known for his "14 Principles in Quality," which outline the key principles of quality management, and his emphasis on the importance of statistical process control and continuous improvement, PDCA.

- 7. Joseph Juran Juran is a founder of the Juran Institute in Wilton, Connecticut. He promoted the concept known as Business Process Quality, which is a technique of Cross-Functional Quality Improvement • He is considered one of the pioneers of the modern quality management movement and is known for his development of the "Juran Trilogy," • which consists of three critical components of quality management: quality planning, quality control, and quality improvement. • Cost of the quality, • SPC Quality He predicted the quality of Japanese goods would overtake the quality of goods produced in US by Mid-1970s because of Japan’s revolutionary rate of quality improvement

- 8. Armand V Feigenbaum was the originator of “total quality control”, often referred to as total quality. He defined it as: “An effective system for integrating quality development, quality maintenance and quality improvement efforts of the various groups within an organization, so as to enable production and service at the most economical levels that allow full customer satisfaction”. He saw it as a business method and proposed three steps to quality: • Quality leadership • Modern quality technology • Organizational commitment

- 9. Philip B. Crosby: Crosby is known for emphasizing the importance of prevention over inspection in quality management. He introduced the concept of "zero defects," which aims to eliminate defects and errors in a process or product. Crosby is also known for his Four Absolutes of Quality: 1- The definition of quality is conformance to requirements. 2- The system of quality is prevention. 3- The performance standard is zero defects. 4- The measurement of quality is the price of non-conformance. Crosby also introduced the idea of "quality is free," which is the notion that the cost of preventing defects is always lower than the cost of dealing with defects after they occur. Top Management in Quality, 14 steps for quality improvement

- 10. Kaoru Ishikawa: Ishikawa is a Japanese quality management expert known for developing the cause and effect diagram, also known as the "Ishikawa diagram" or "fishbone diagram." This tool is used to identify the root causes of a problem and is a critical tool in root cause analysis. Ishikawa is also known for emphasizing the importance of involving all employees in the quality management process. Ishikawa also introduced the concept of "total quality control," involving all employees in the quality control process and using data and statistical analysis to drive continuous improvement.

- 11. Walter Shewhart - Walter Shewhart is credited with developing the concept of "statistical process control," which involves using statistical methods to monitor and control manufacturing processes to produce goods of consistent quality. Shewhart also introduced the idea of "control charts," which are graphical tools used to monitor process performance over time and identify when a process is out of control. His ideas have been widely adopted by industries worldwide and have played a significant role in developing modern quality control techniques.

- 12. Dr Genichi Taguchi Genichi Taguchi is a name which will forever be associated with quality control. His pioneering thoughts and subsequent work changed the field forever. His focus was into greater customer satisfaction by looking into the loss of quality. He challenged the prevalent ideas of production where it was okay if a defect was within a tolerance limit. His methods famously known as the Taguchi Methods have left a lasting imprint in the field of quality control. • Taguchi Methods • Taguchi Loss Function • Design of Experiments • Robust Design

- 13. Tools and techniques: Benchmarking: Benchmarking is a powerful tool for improving your performance in Total Quality Management (TQM). It involves comparing your processes, products, and outcomes with those of the best performers in your industry or sector. By learning from the best practices of others, you can identify gaps, set goals, and implement changes to enhance your quality and efficiency.

- 14. • Six Sigma is a quality management methodology used to help businesses improve current processes, products, or services by discovering and eliminating defects. • Six Sigma was trademarked by Motorola in 1993. • The name references the Greek letter sigma, which is a statistical symbol that represents a standard deviation. Motorola used the term because a Six Sigma process is expected to be defect-free 99.99966% of the time — allowing for 3.4 defective features for every million opportunities. • Motorola initially set this goal for its own manufacturing operations, but it quickly became a buzzword and widely adopted standard.

- 15. Seven traditional tools: These tools can provide much information about problems in the organization assisting to derive solutions for the same. •Pareto Principle. •Scatter Plots. •Control Charts. •Flow Charts. •Cause and Effect , Fishbone,Ishikawa Diagram. •Histogram or Bar Graph. •Check Lists. •Check Sheets

- 16. New seven management tools: Affinity Diagram [KJ method] •Interrelationship diagram. •Tree diagram. •Prioritization matrix. •Matrix diagram or quality table. •Process decision program chart. •Activity network diagram.

- 17. • Failure Mode and Effects Analysis (FMEA) is an analytical method in quality management to find possible product defects before they occur. It is also known as "Impact Analysis". • Appropriate measures can be taken within the framework of the FMEA to prevent identified potential defects in advance. In this process, the product or process to be evaluated is assessed in terms of its impact on the customer, the probability of occurrence and the probability of detection using key figures. In this way, the process can be dealt with appropriately using suitable methods.

- 18. • FMEA also known as Risk Analysis, is preventive measure to systematically display the causes, effects and possible actions regarding observed failures • Objective is to prioritize the expected failures and attempt to eliminate their causes • FMEA is a group of activities to understand and evaluate potential failure of product or process and its effects, and identify actions that eliminate or reduce the potential failures. • FMEA is an engineering technique used to define, identify and eliminate potential failures/ problems/ errors that occur in system, design, process and service ‘before they reach the customer’ • FMEA is a ‘before-the-event’ action and is done when existing systems/processes/products are changed or redesigned

- 19. • A Quality Circle or Quality Control Circle is a group of people from the same area, coming together voluntarily to identify, analyze the work area problems, and find effective solutions. • The quality circle members present the solutions to management and implement them after approval. Review and follow-up of implementation are also the responsibility of the QC members. • Quality Circle is a voluntary group of 4 to 6 members. • Members are usually from one section or department. • One senior member acts as a facilitator • Identify a problem in the work area, meet and discuss the problem regularly, ideally once a week. • Identify and implement solutions in a standardized methodology.

- 20. • Quality Function Deployment (QFD) is a TQM (Total Quality Management) tool that systematically develops the customers need and expectations and finally convert them into detailed engineering specifications and plans to produce the products that fulfill those requirements.

- 22. The goal is the total elimination of all losses, including breakdowns, equipment setup and adjustment losses, idling and minor stoppages, reduced speed, defects and rework, spills and process upset conditions, and startup and yield losses. The ultimate goals of TPM are zero equipment breakdowns and zero product defects, which lead to improved utilization of production assets and plant capacity.