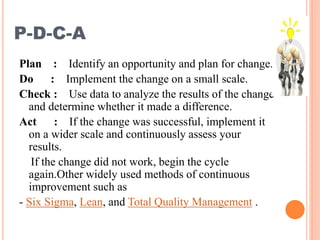

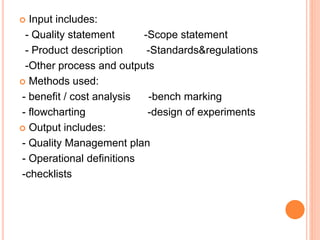

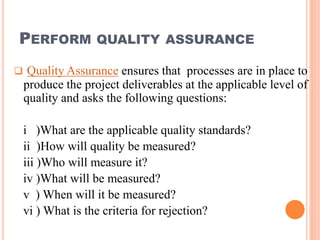

Quality management involves overseeing all activities needed to maintain a desired level of excellence. It defines quality as meeting requirements and focuses on constantly pursuing improvement. Quality management processes include planning, assurance, and control activities. Key aspects of quality management include establishing a quality policy and objectives, defining responsibilities, implementing corrective actions and continuous improvement through methods like Six Sigma, Lean, and PDCA cycles.

![WHAT IS QUALITY?

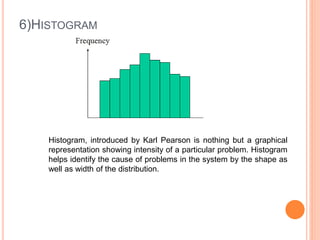

“Quality” - The degree to which a set of inherent

characteristics fulfils requirements.

[PMBOK Guide V.5]

Managing quality means constantly pursuing

excellence

making sure that what your organisation does

is fit for purpose and improvement.](https://image.slidesharecdn.com/qualitymanagement-181104163013/85/Quality-management-4-320.jpg)

![QUALITY POLICY

Top management must ensure that the quality

policy:

Is appropriate to the organisation

Includes a commitment to requirements and

continual improvement

Provides a basis for establishing and quality

objectives

Is communicated and understood within the

organisation

Is periodically reviewed for suitability

[ISO 9001-2008 recommendation]](https://image.slidesharecdn.com/qualitymanagement-181104163013/85/Quality-management-14-320.jpg)