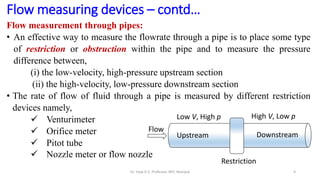

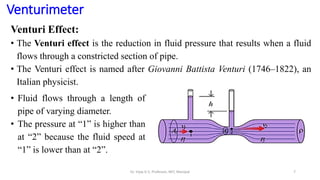

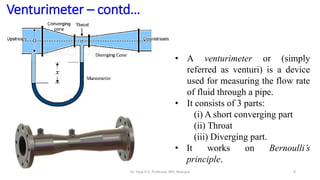

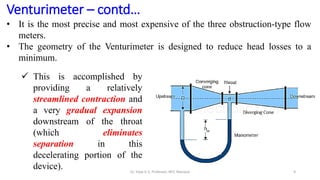

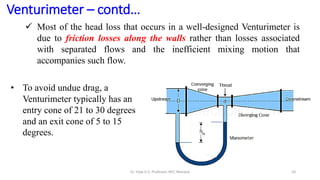

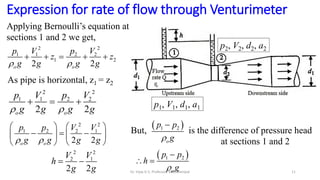

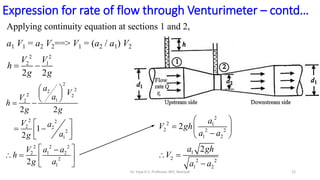

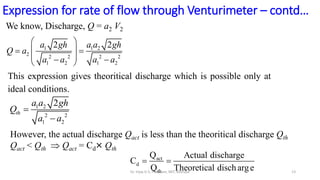

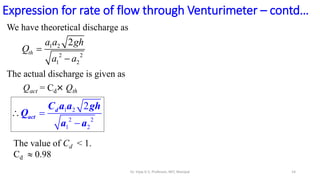

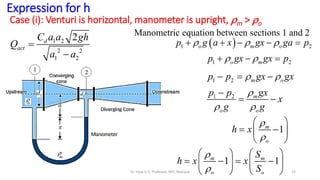

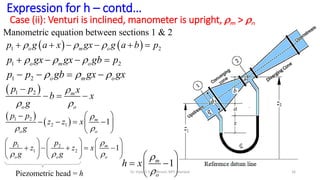

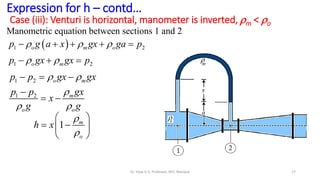

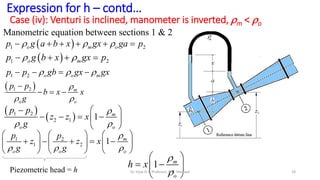

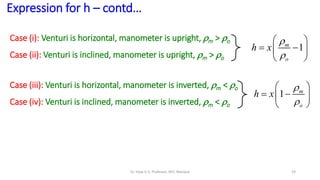

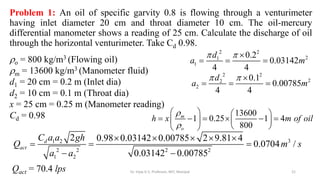

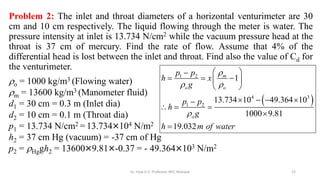

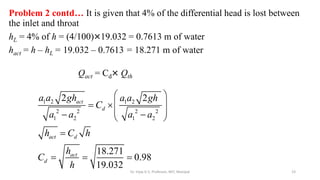

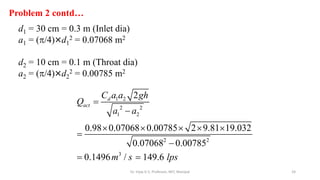

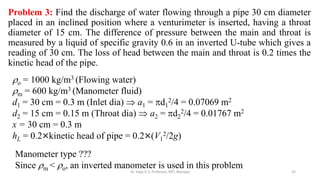

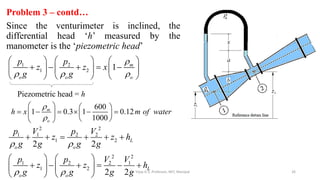

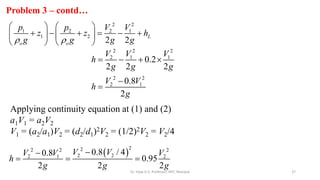

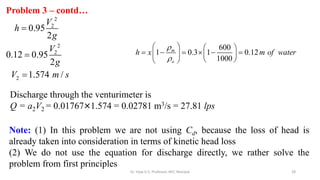

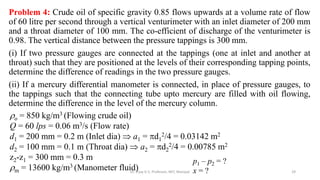

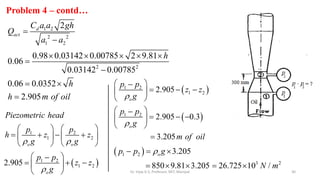

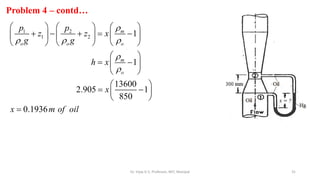

This document discusses flow measurement using Venturimeters. It begins by deriving the theoretical expression for flow rate through a Venturimeter using Bernoulli's equation and the continuity equation. It then accounts for real-world losses by introducing a discharge coefficient. The document also derives the manometric equations relating the pressure differences measured by the Venturimeter to the height of manometers in various configurations depending on the orientation of the Venturimeter and whether the manometer is upright or inverted. In total, it considers four cases for these orientations.