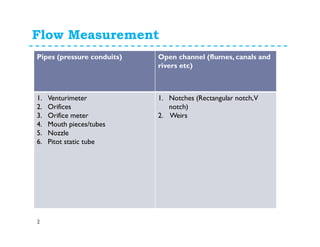

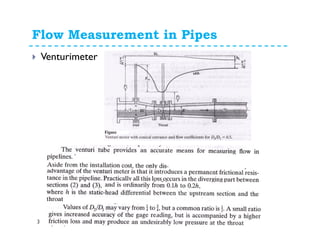

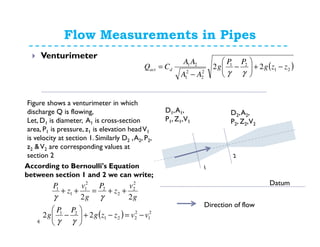

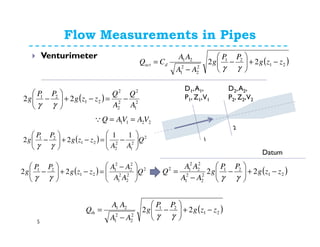

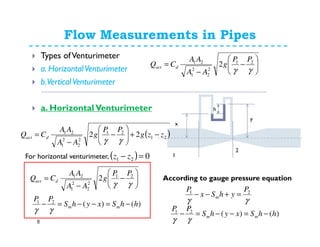

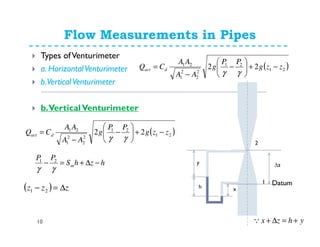

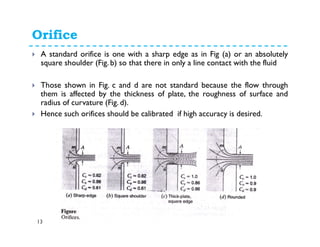

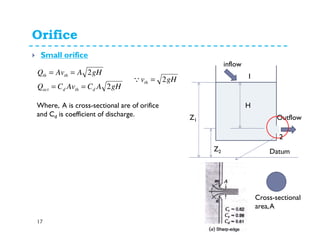

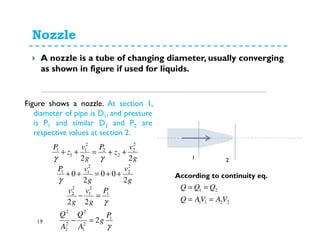

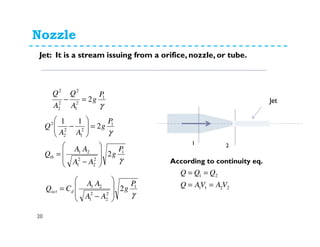

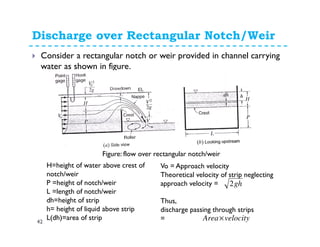

This document discusses various flow measurement techniques including venturimeters, orifices, mouthpieces, pitot tubes, weirs and notches. It provides detailed explanations and equations for venturimeters and orifices. Venturimeters use the Bernoulli's equation to relate the pressure difference between two sections to the flow rate. Orifices use the relationship between head loss and flow rate. The document also defines various coefficients used in flow measurements like coefficient of contraction, velocity, and discharge. It discusses types of venturimeters and orifices based on their orientation and geometry.

![Discharge over Triangular Notch (V-Notch)

37

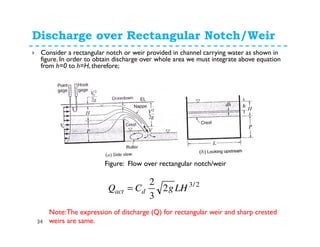

In order to obtain discharge over

whole area we must integrate above

equation from h=0 to h=H, therefore;

( )[ ]2/5

2/tan2

15

8

HgCQ dact θ=](https://image.slidesharecdn.com/flowmeasurement-150316030307-conversion-gate01/85/Flow-measurement-37-320.jpg)

![Discharge over Triangular Notch (V-Notch)

44

In order to obtain discharge over

whole area we must integrate above

equation from h=0 to h=H, therefore;

( ) ( )( )( )

( ) ( ) dhhhHgQ

ghhHdhQ

H

H

∫

∫

−=

−=

0

0

2/tan22

22/tan2

θ

θ

( ) ( )

( )

=

−= ∫

2/5

0

2/32/1

15

4

2/tan22

2/tan22

HgQ

dhhHhgQ

H

θ

θ

( )[ ]2/5

2/tan2

15

8

HgQ θ=

( )[ ]2/5

2/tan2

15

8

HgCQ dact θ=](https://image.slidesharecdn.com/flowmeasurement-150316030307-conversion-gate01/85/Flow-measurement-44-320.jpg)