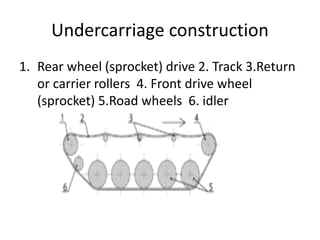

The undercarriage is the system that allows construction equipment to travel from place to place by converting the rotating motion of wheels or tracks into linear motion. It must be wear resistant to handle high impact loads and severe conditions. Tracks better distribute weight than wheels and allow equipment to travel in soft ground. Special rubber-padded tracks can be used on paved surfaces. The main undercarriage components are the track frame, equalizer bar, drive sprocket, idler wheels, track rollers, carrier rollers, and track chain assembly.