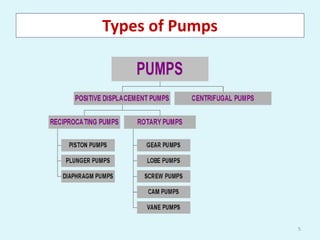

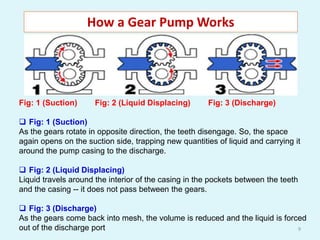

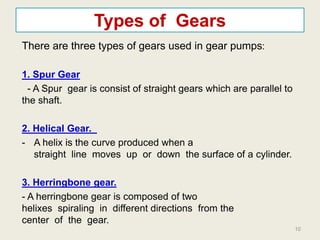

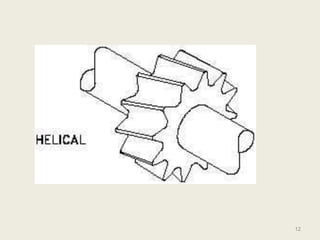

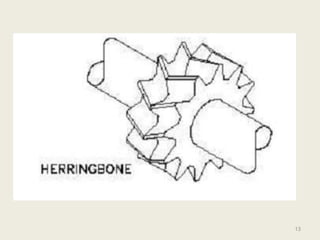

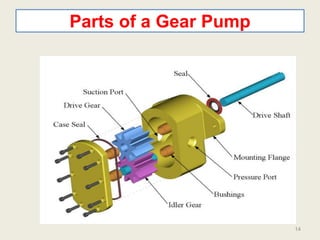

This document discusses gear pumps, including their operation, types, maintenance, and uses. It begins by defining pumps as devices that add energy to fluids to move them from one point to another. It then explains that gear pumps are a type of rotary, positive displacement pump that uses meshing gears to pump liquids. The document describes how gear pumps work by trapping liquid between gear teeth and casing as the gears rotate. It also discusses gear pump components, maintenance like checking clearances and changing seals, the use of relief valves for safety, and applications like pumping fuels and lubricants.