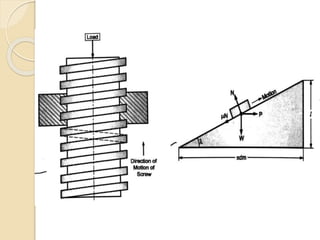

(1) The document discusses power screws, which are screw and nut systems that convert rotational motion to linear motion.

(2) Power screws have advantages like high efficiency in transmitting power but limitations like lower strength than V-threads.

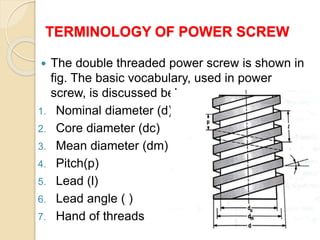

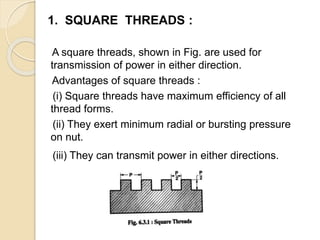

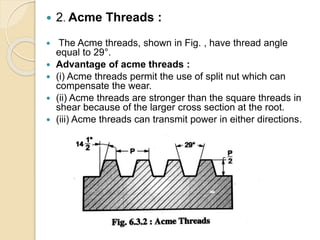

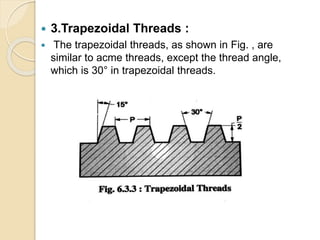

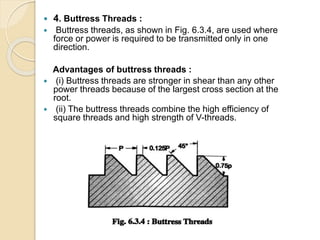

(3) Common forms of threads for power screws include square, ACME, trapezoidal, and buttress threads, which vary in properties like strength, efficiency, and direction of power transmission.