This document provides an overview of governors and their functions. It discusses the main components and workings of centrifugal governors, including Porter and Hartnell governors. The key points covered are:

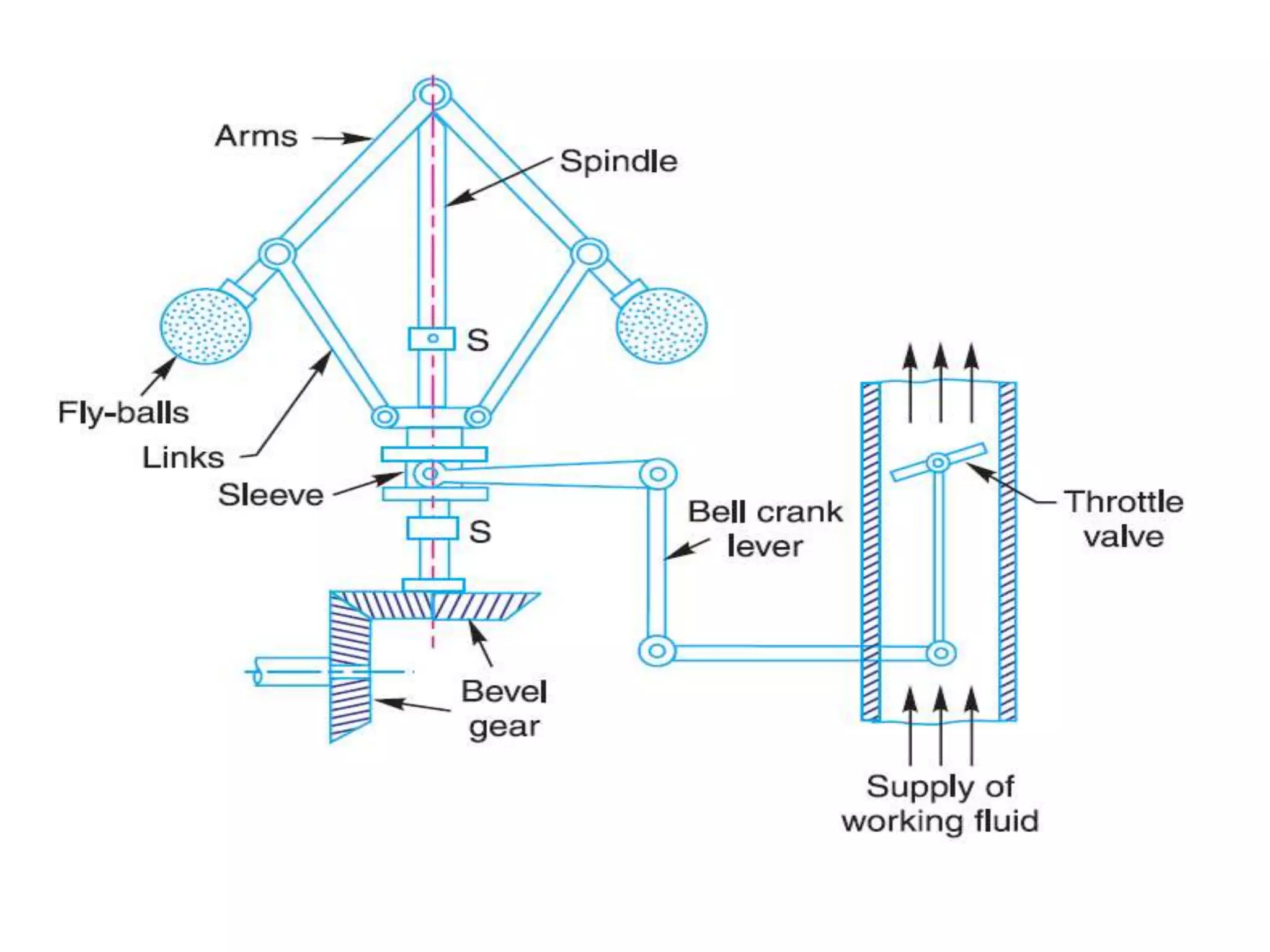

- Governors regulate engine speed by automatically controlling the supply of working fluid as load conditions vary.

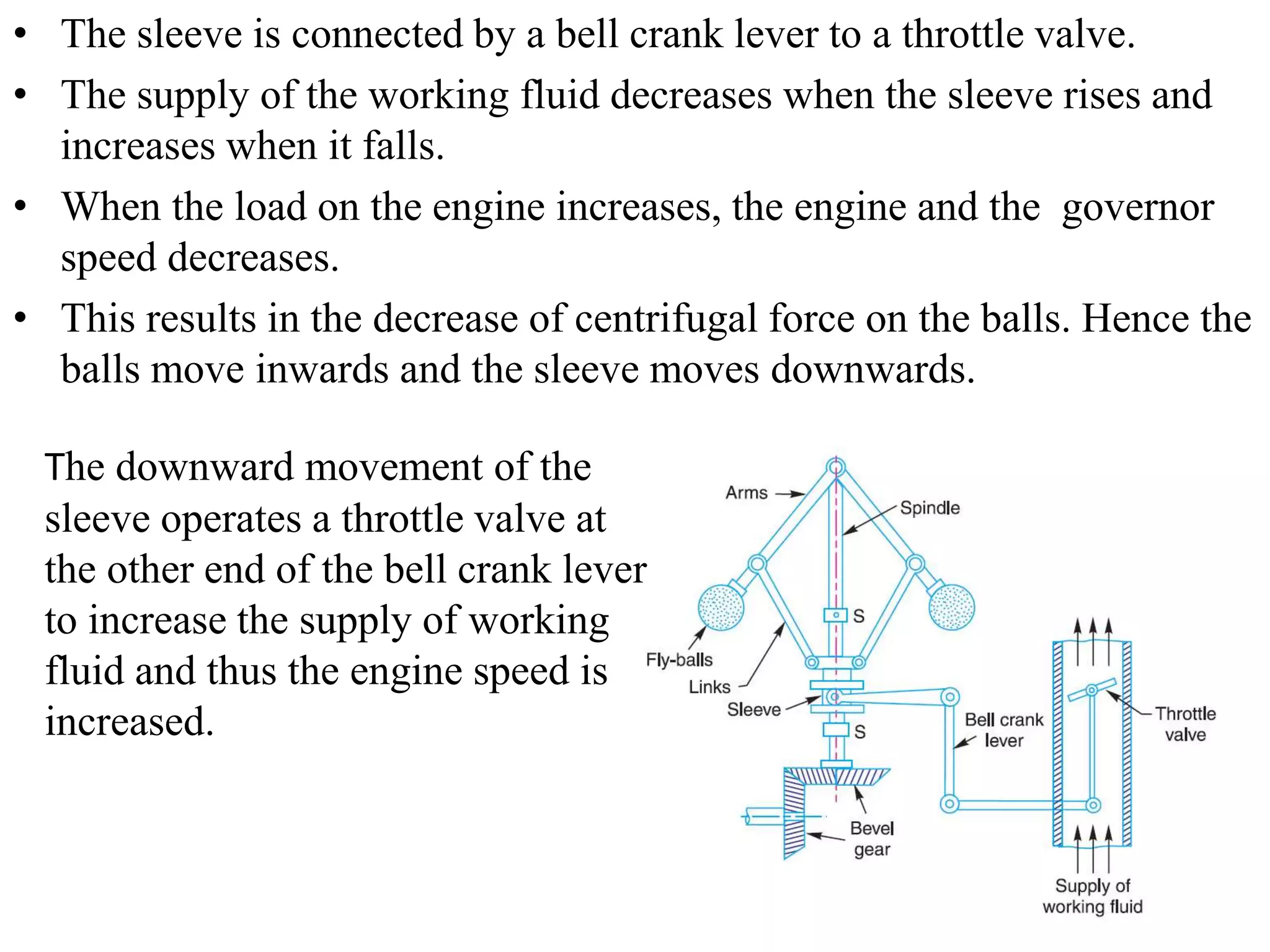

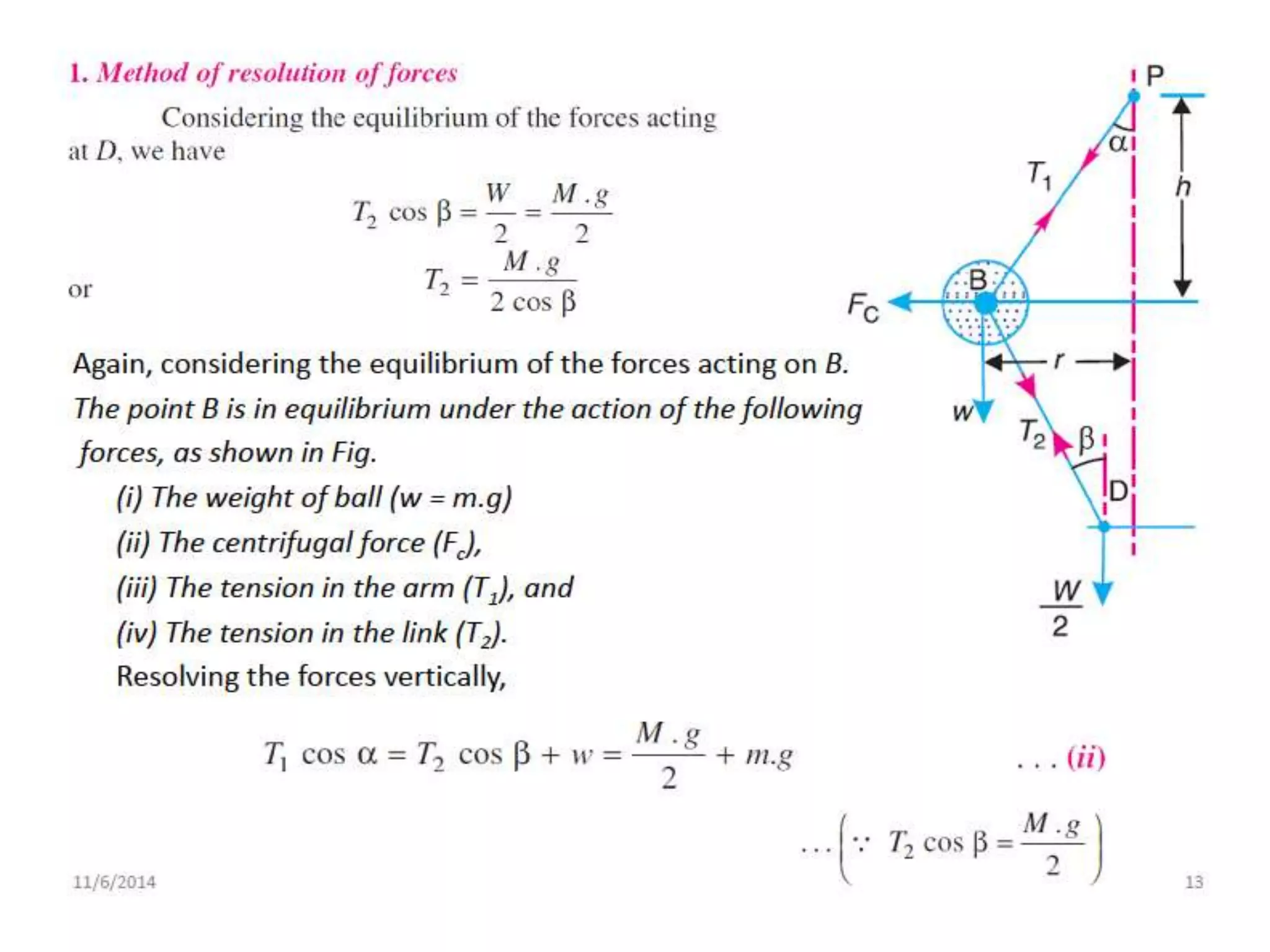

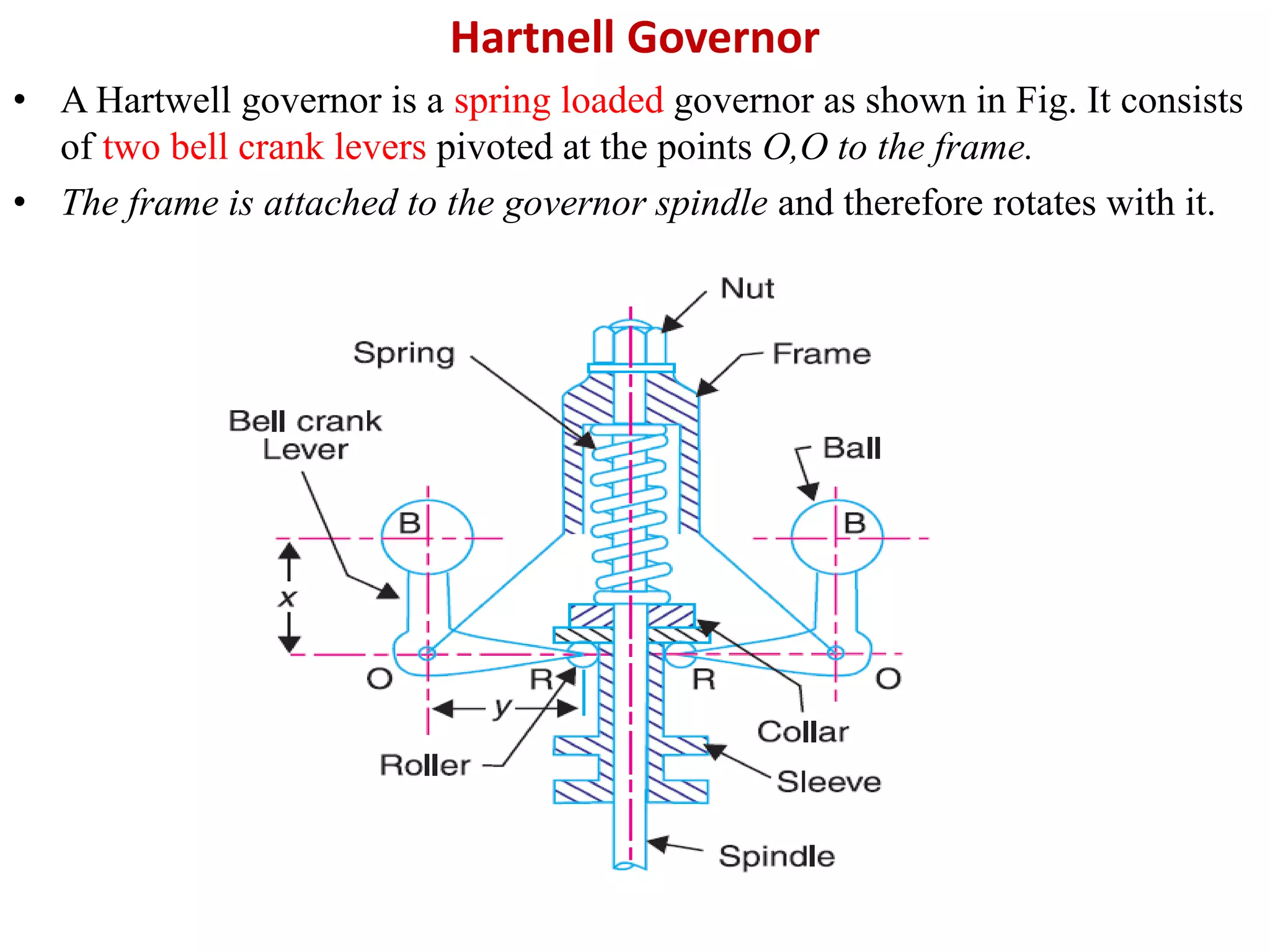

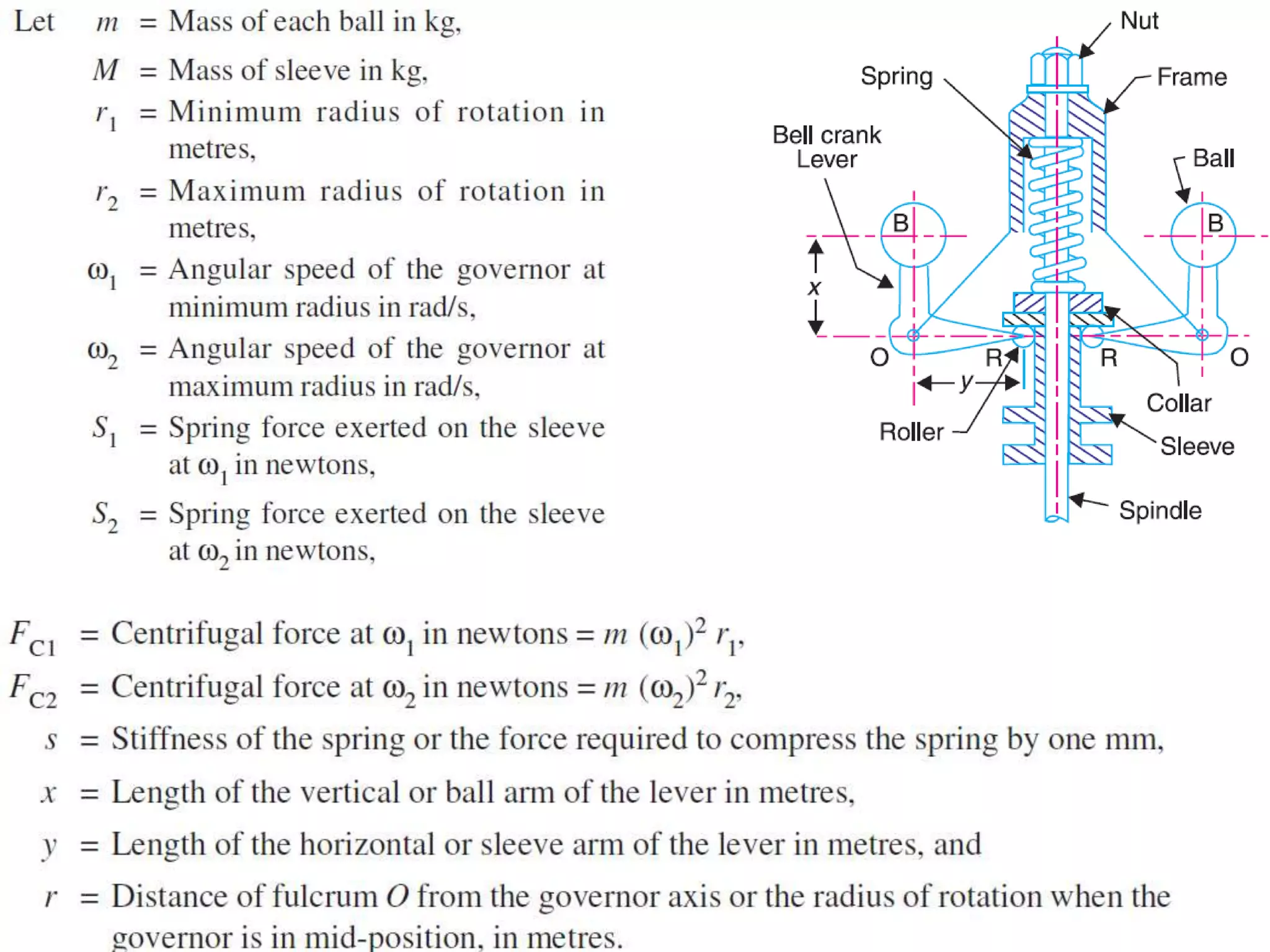

- Centrifugal governors work by balancing the centrifugal force on rotating balls with a controlling force. Porter governors use a central load while Hartnell governors use springs.

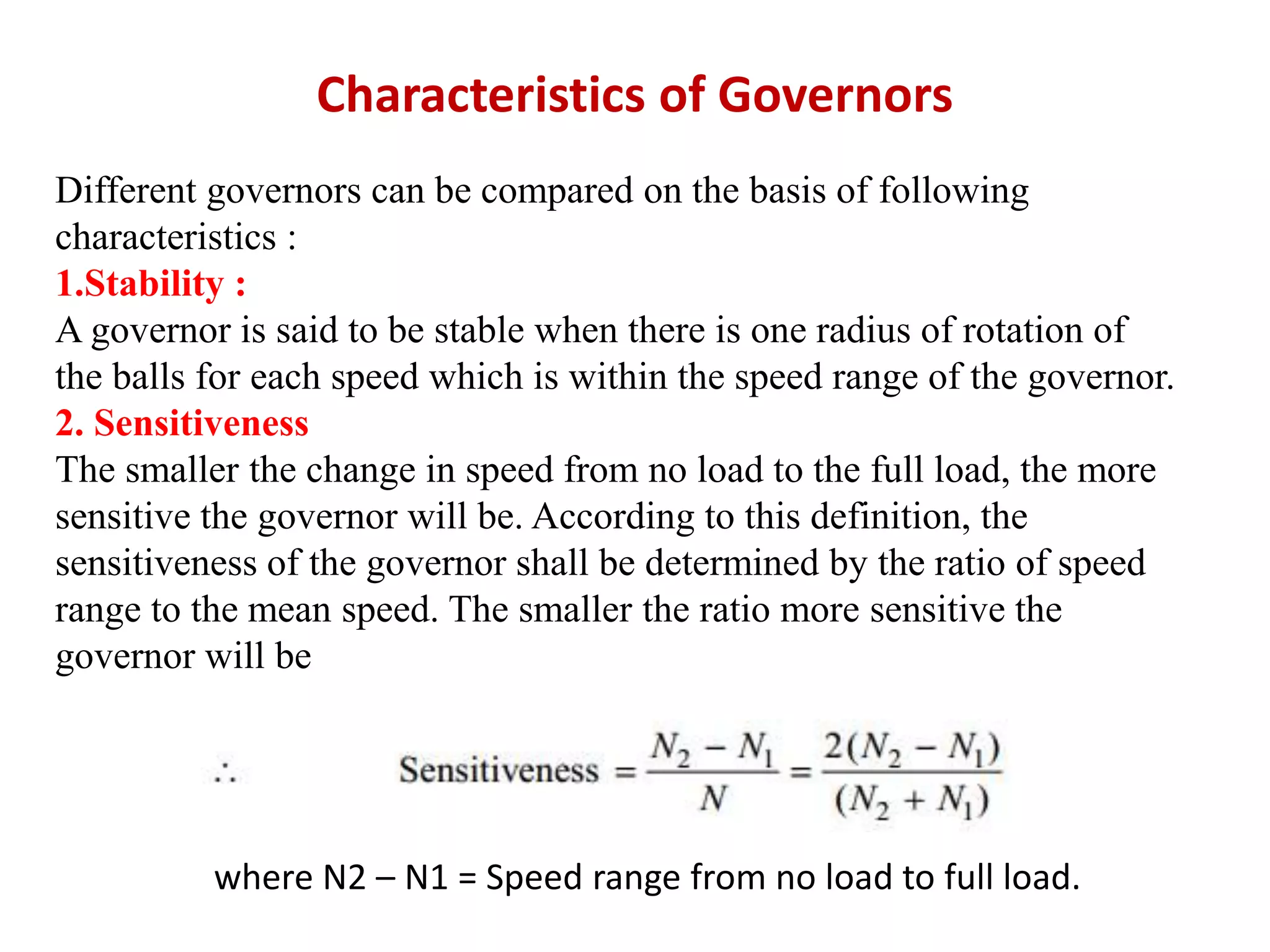

- Other topics discussed include stability, sensitivity, isochronism, effort/power, and hunting in governors. Terms like height, equilibrium speed, and sleeve lift are also defined.