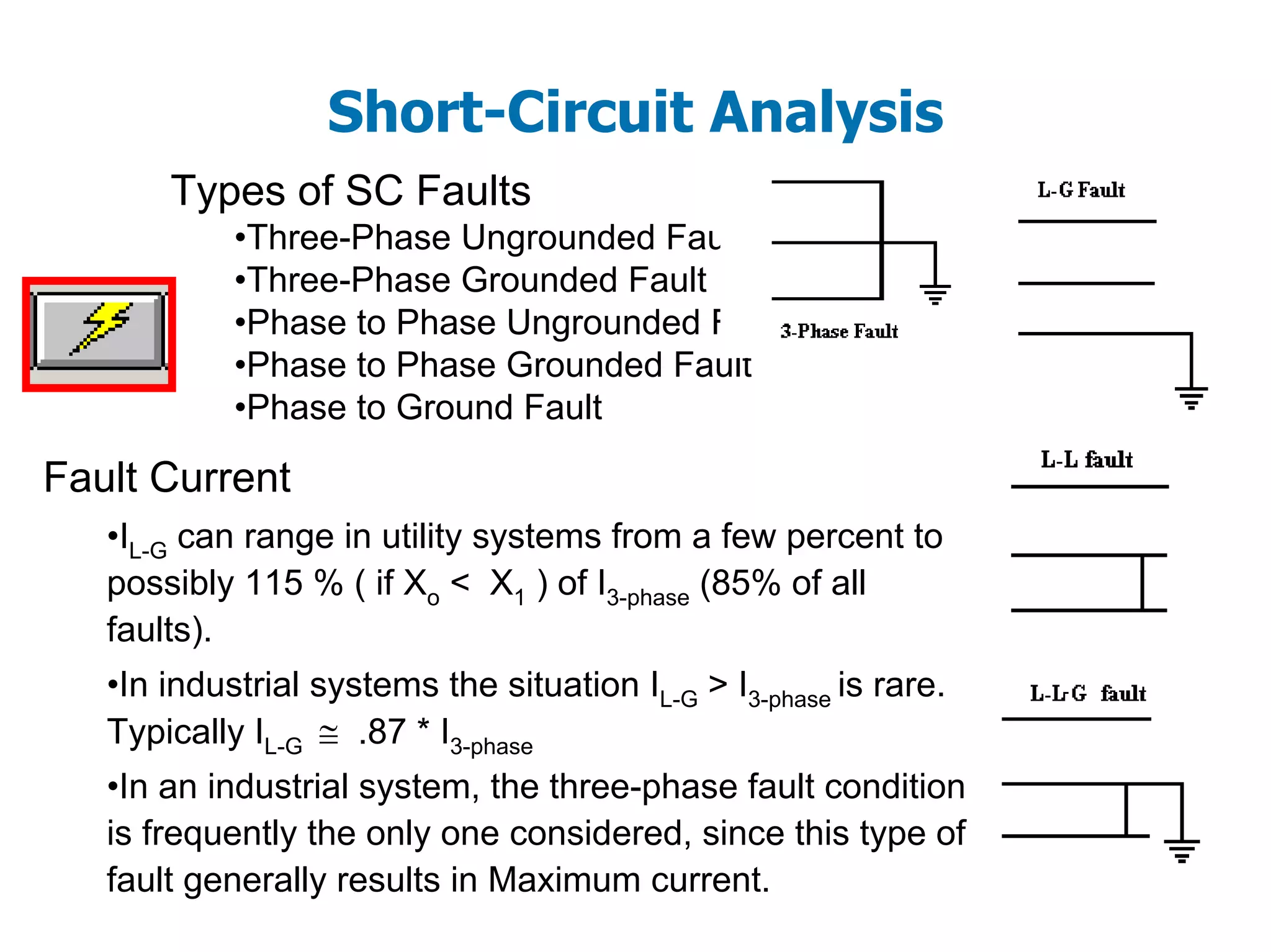

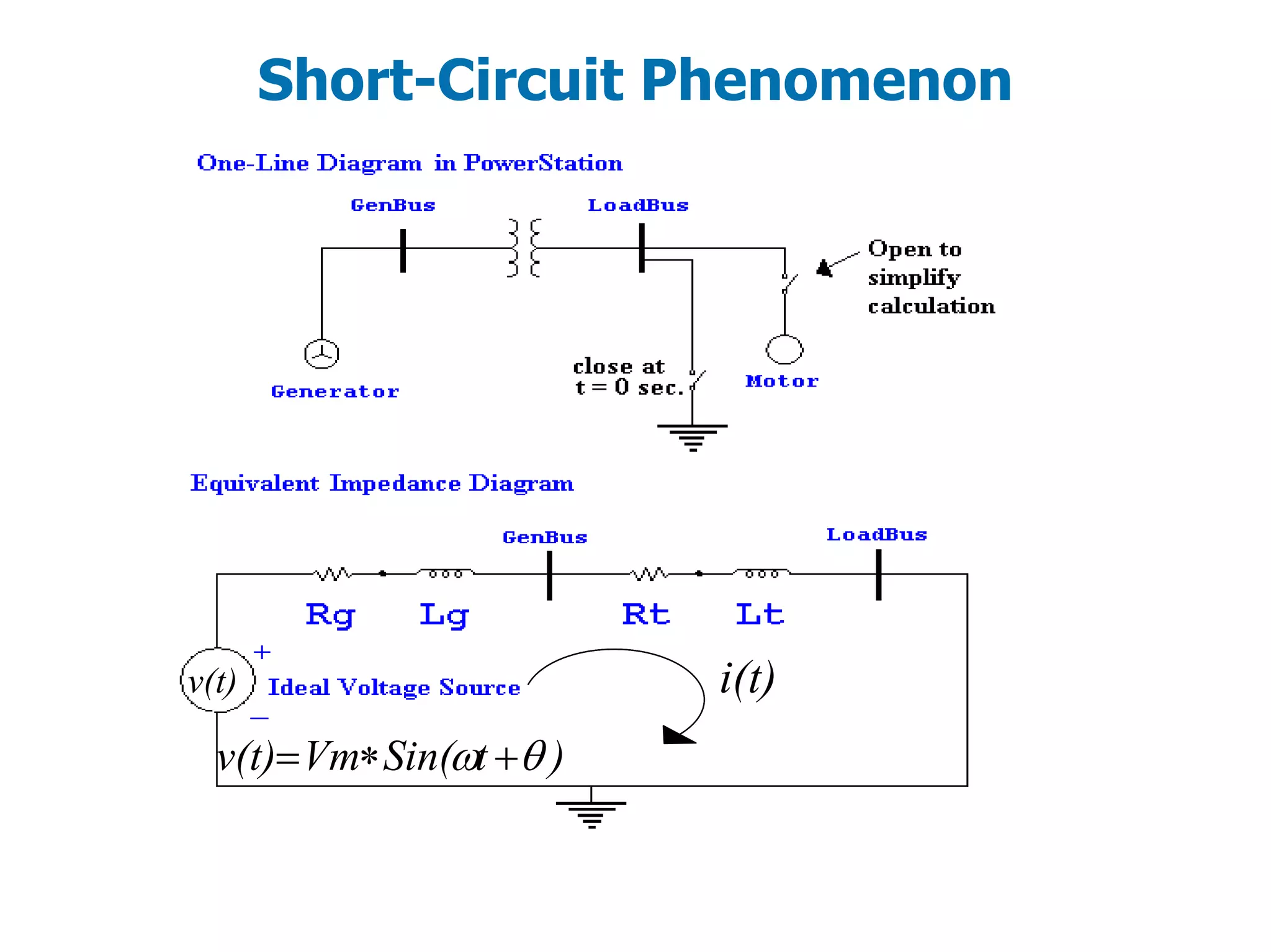

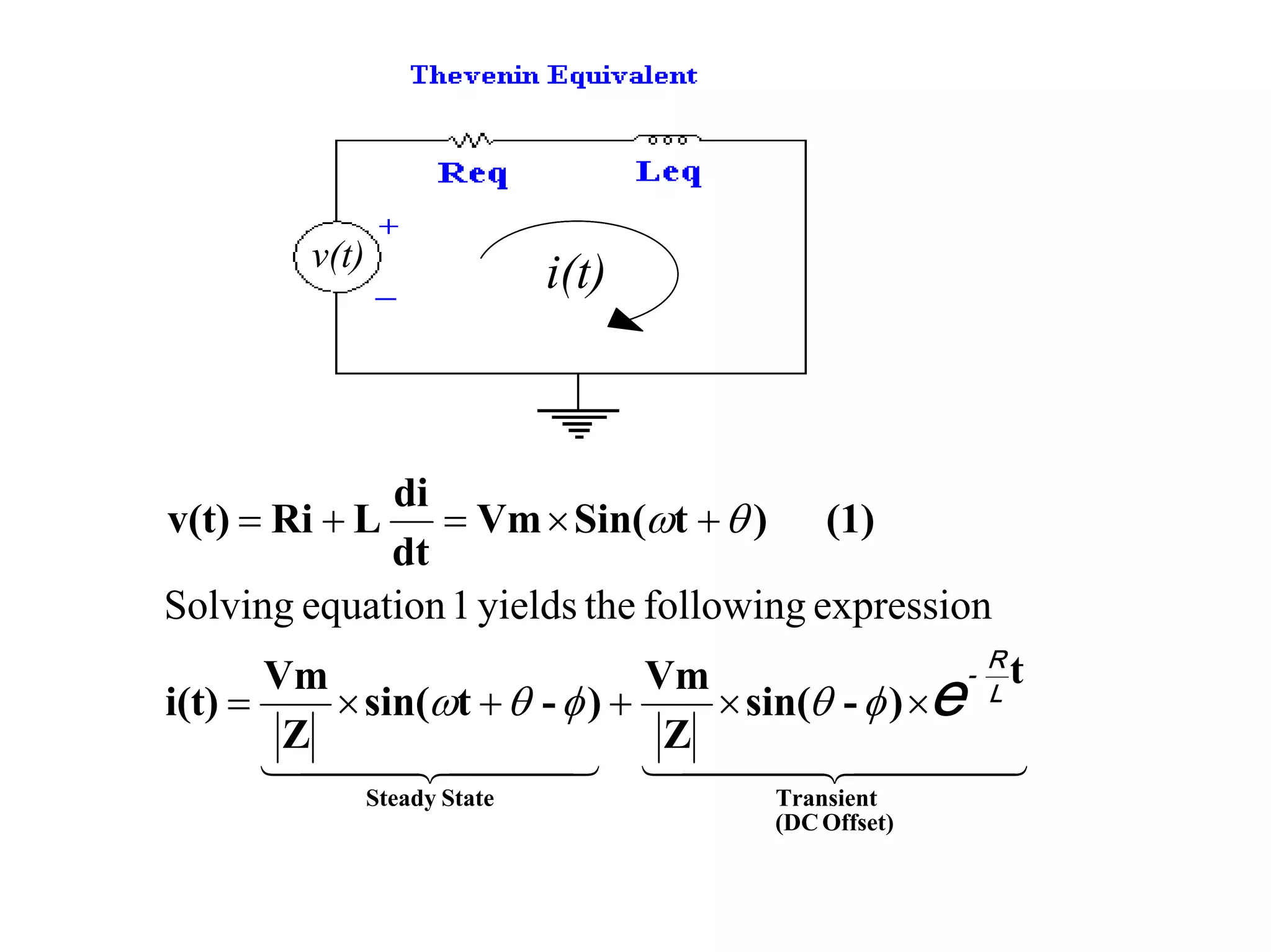

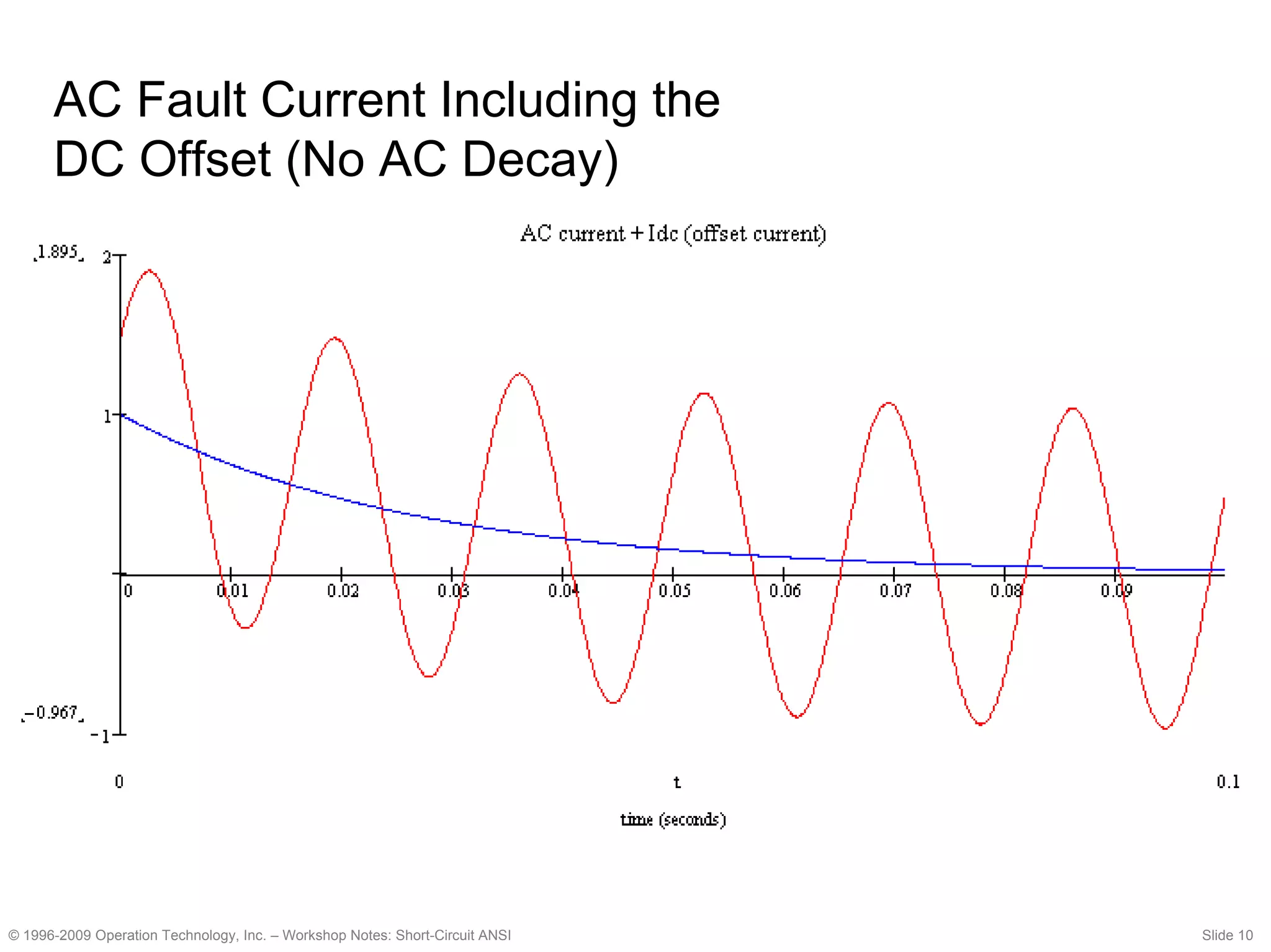

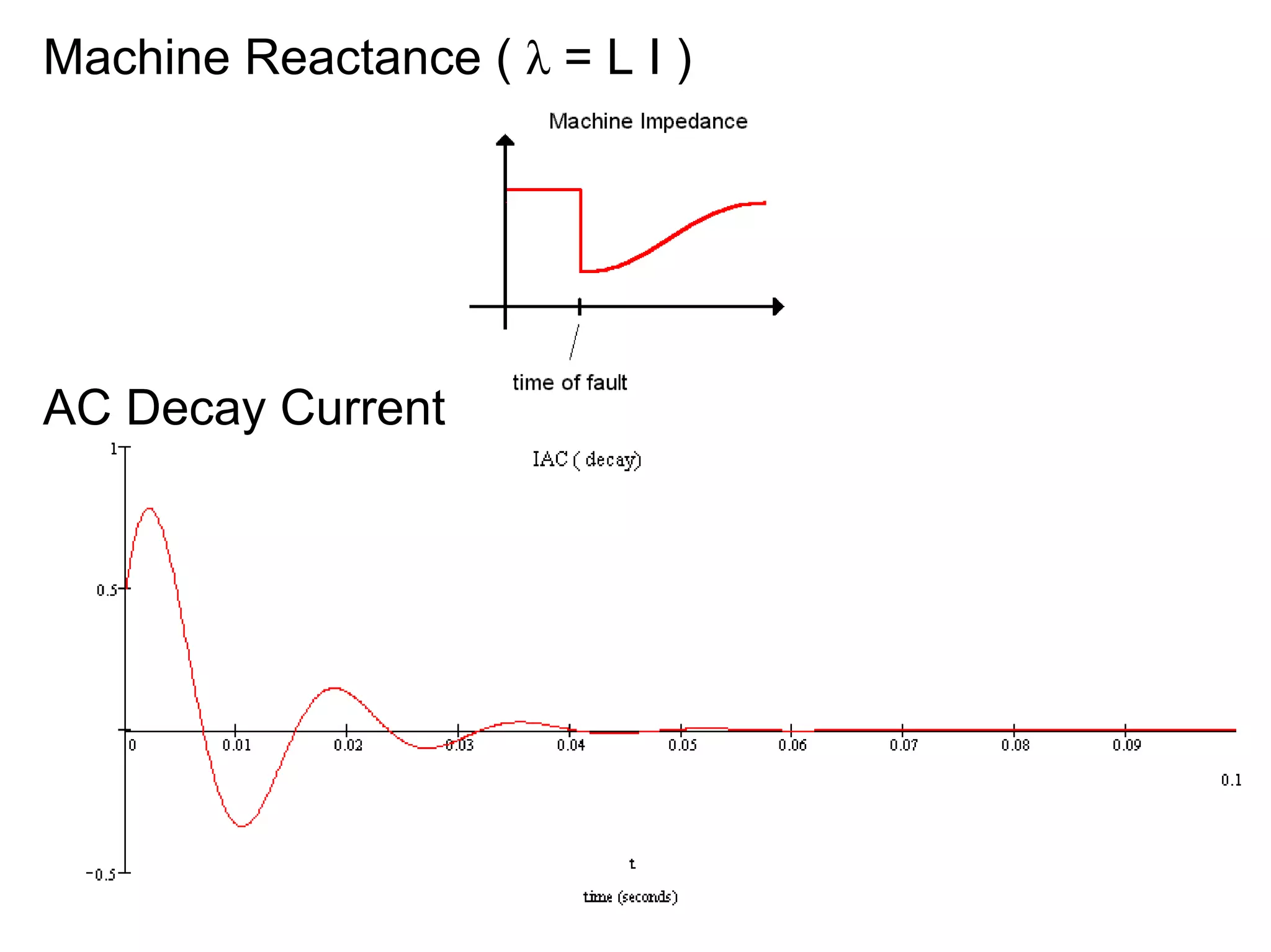

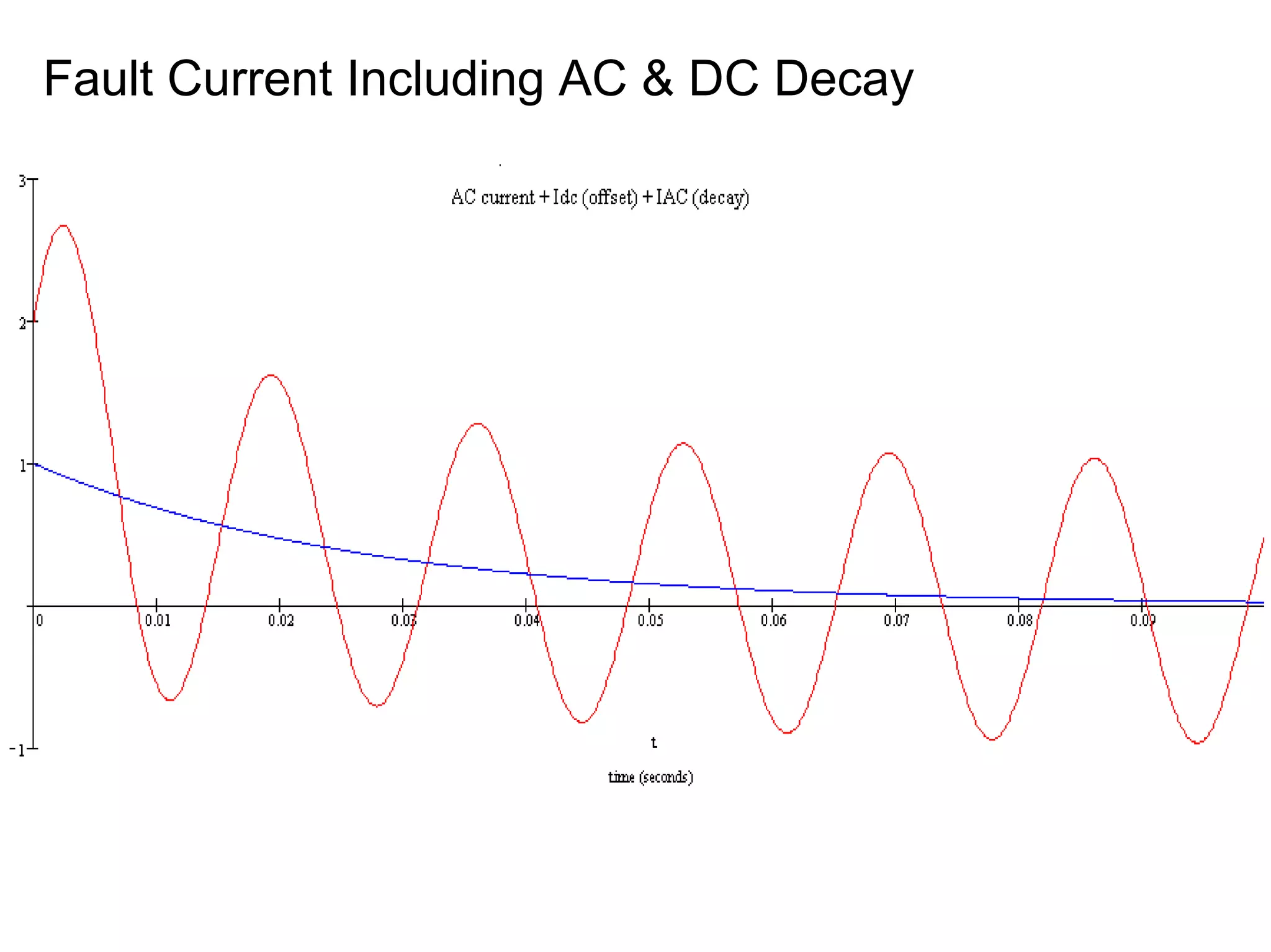

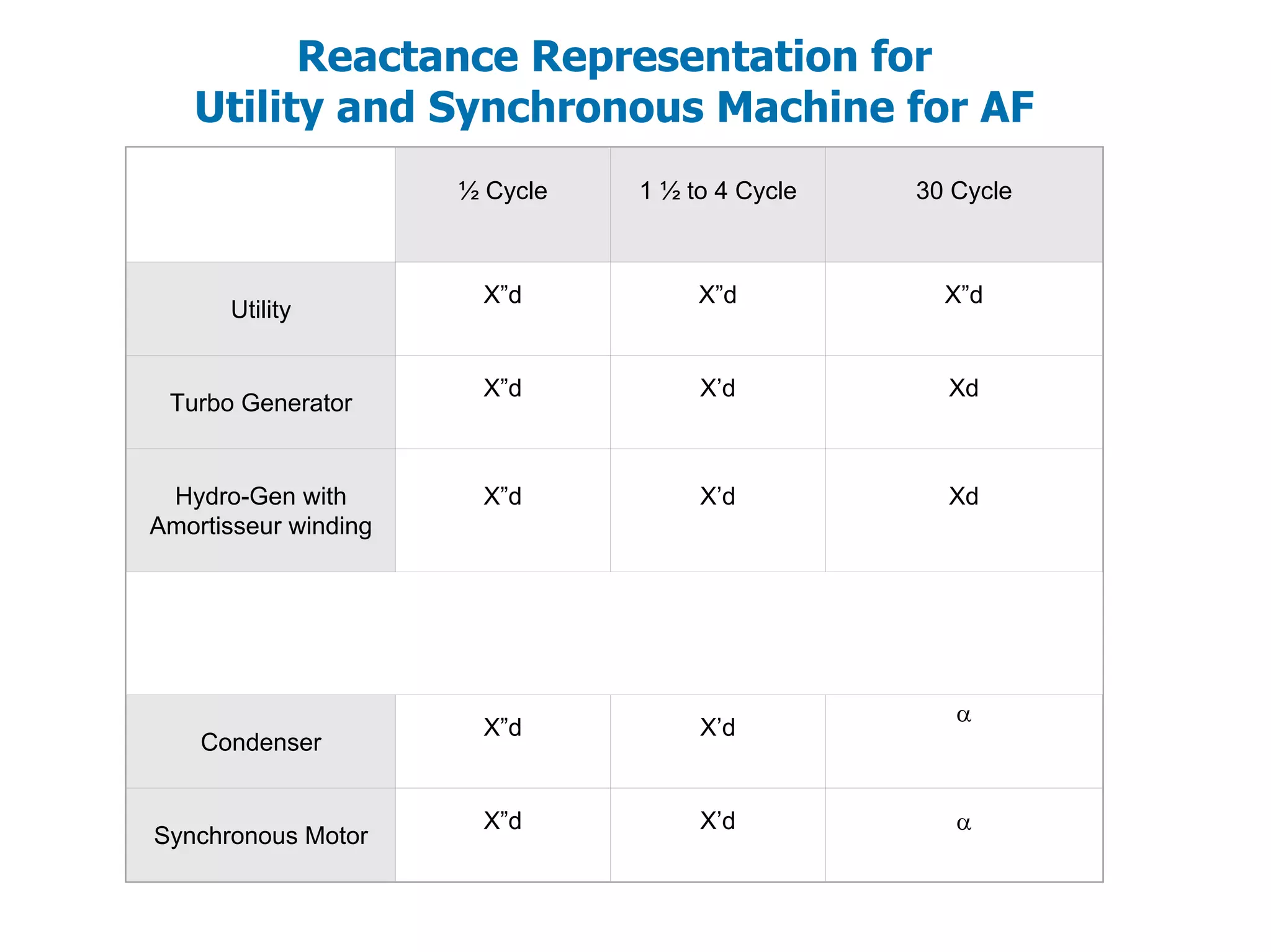

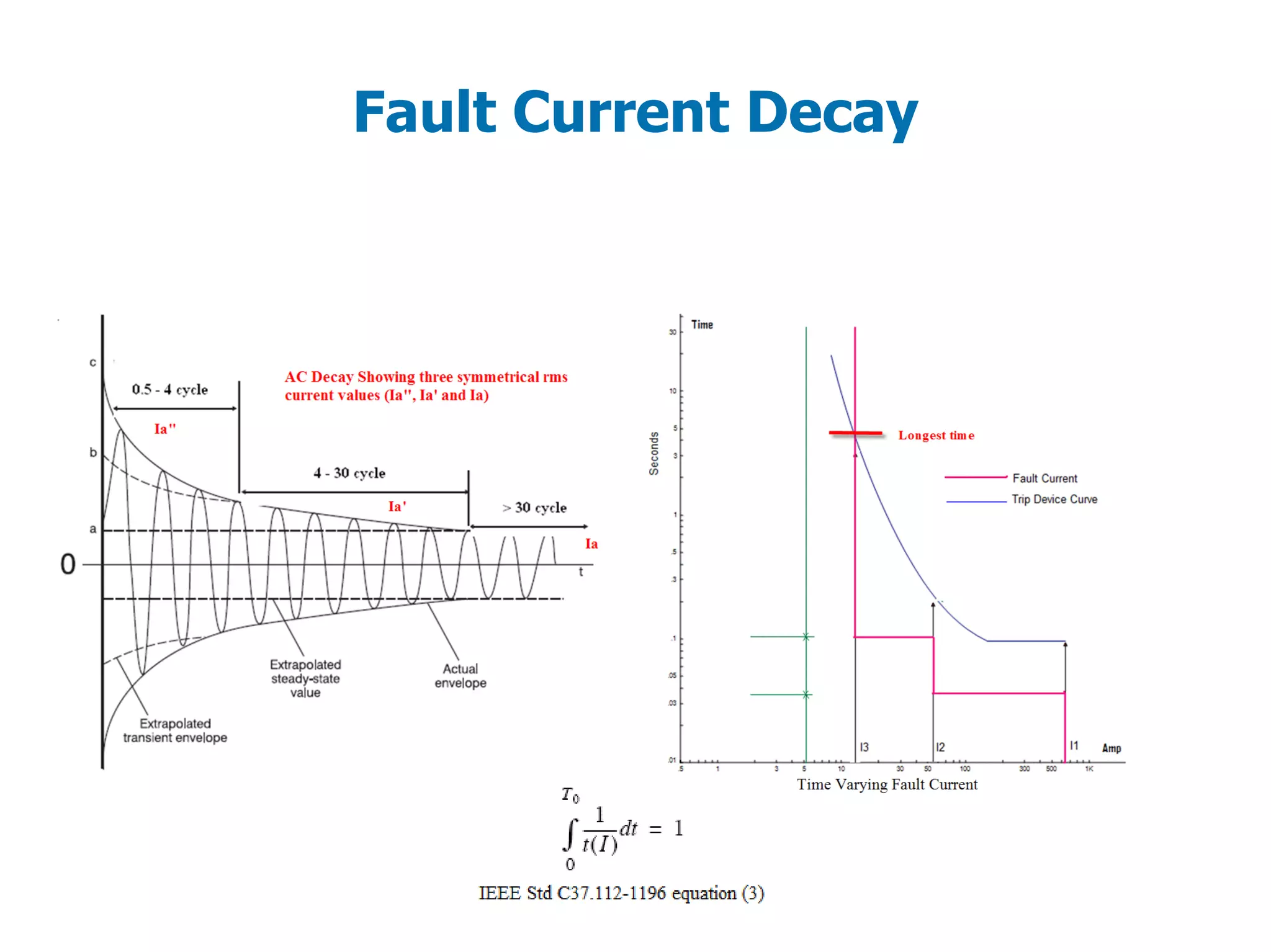

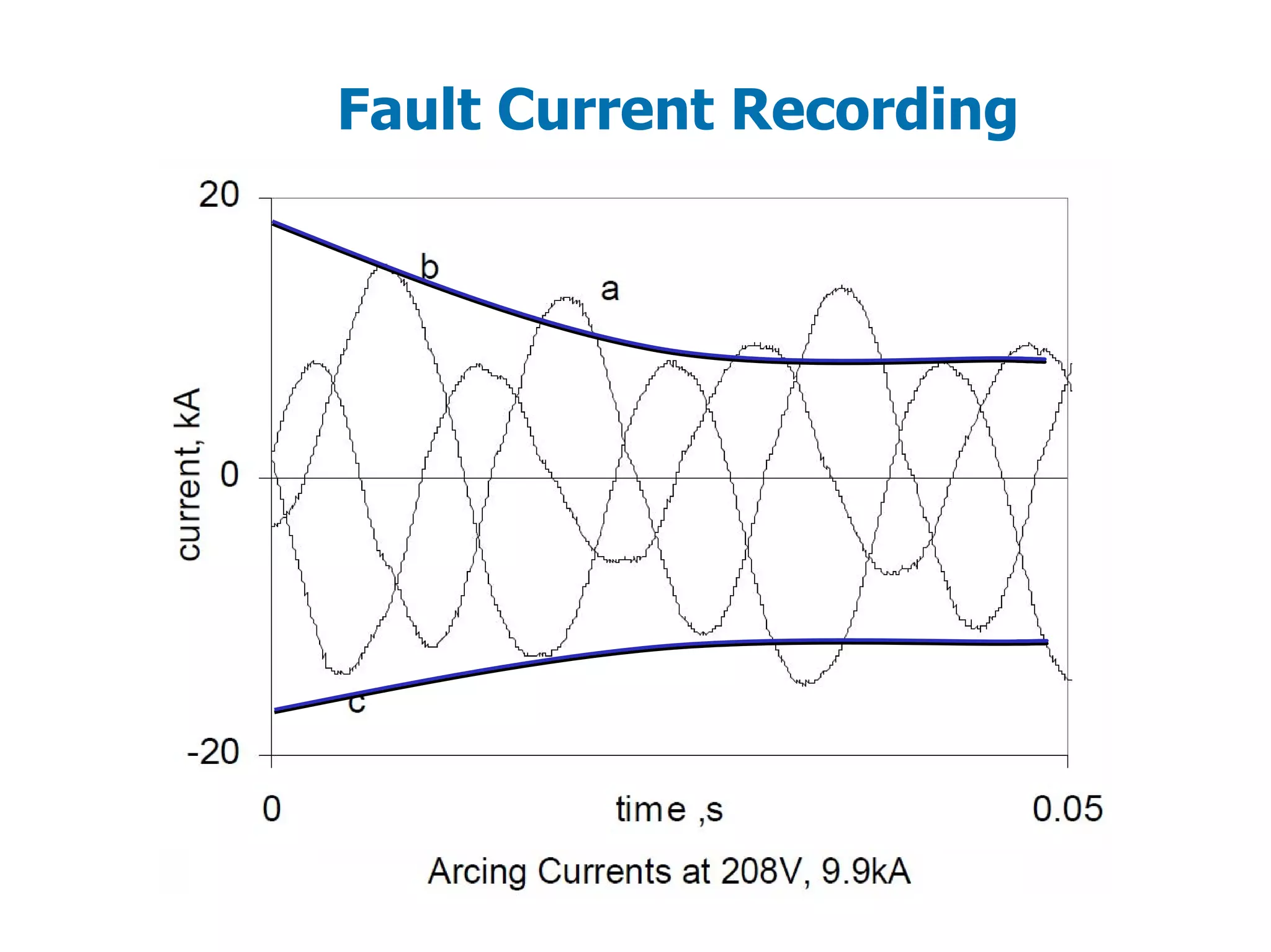

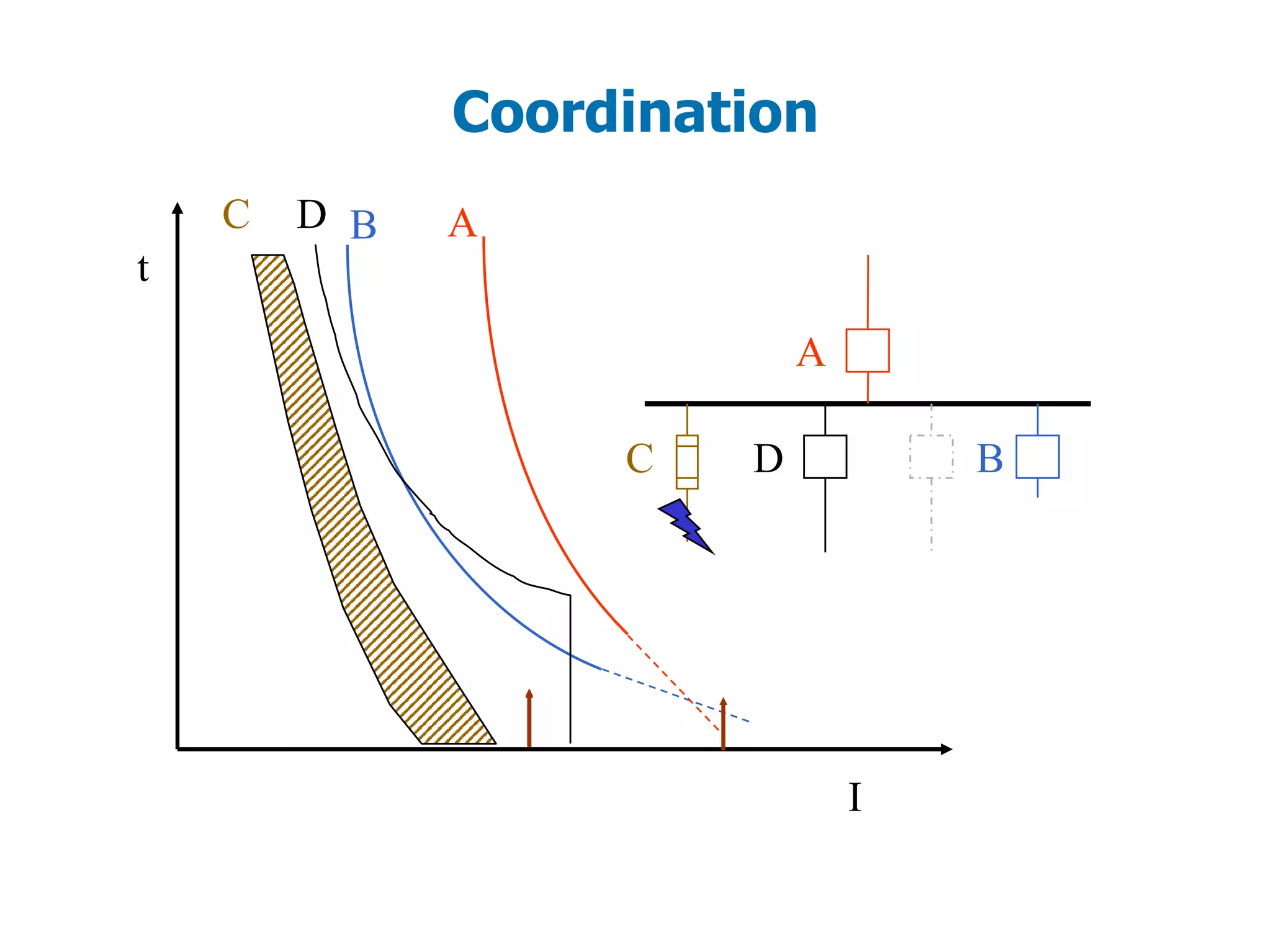

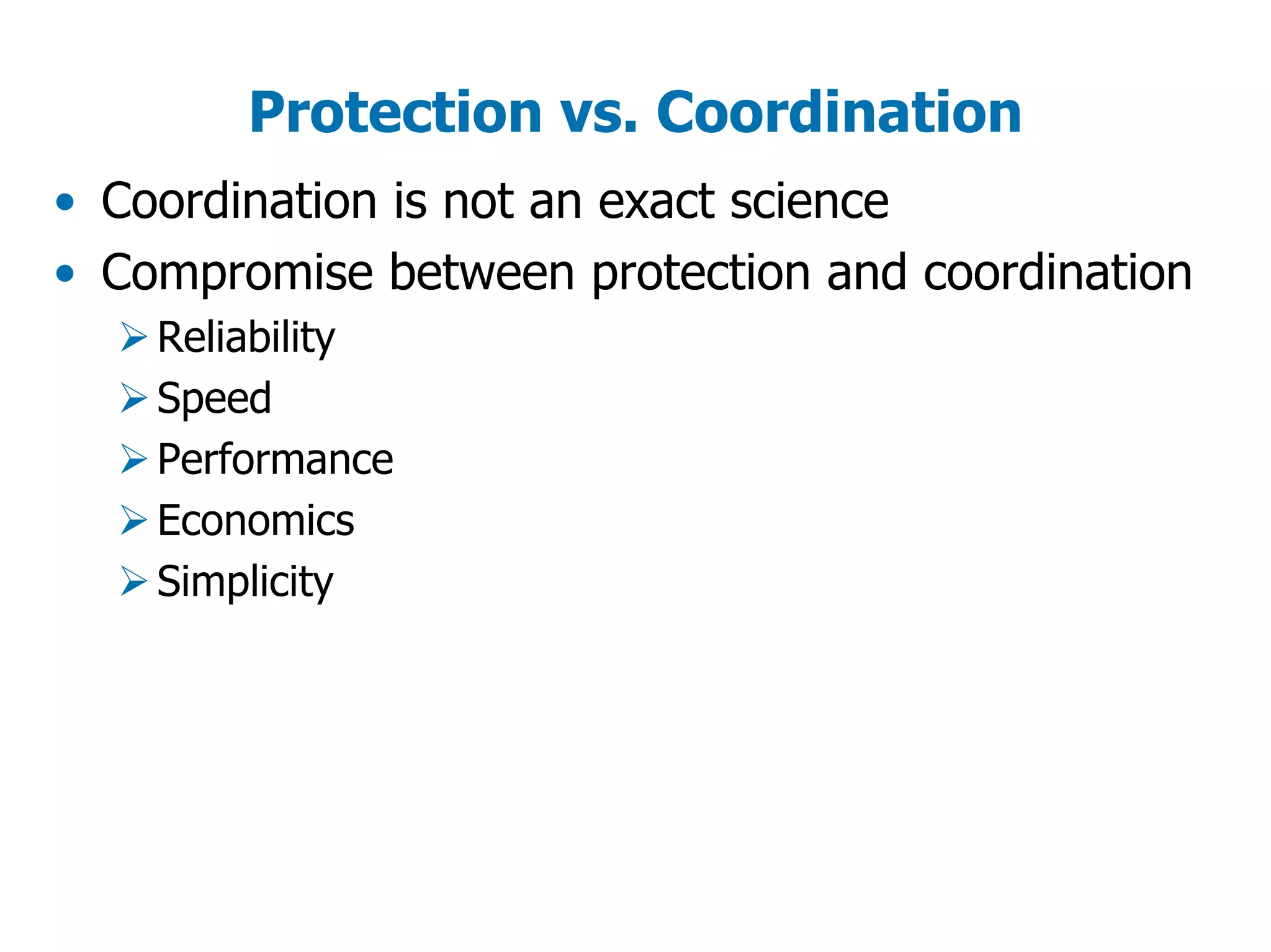

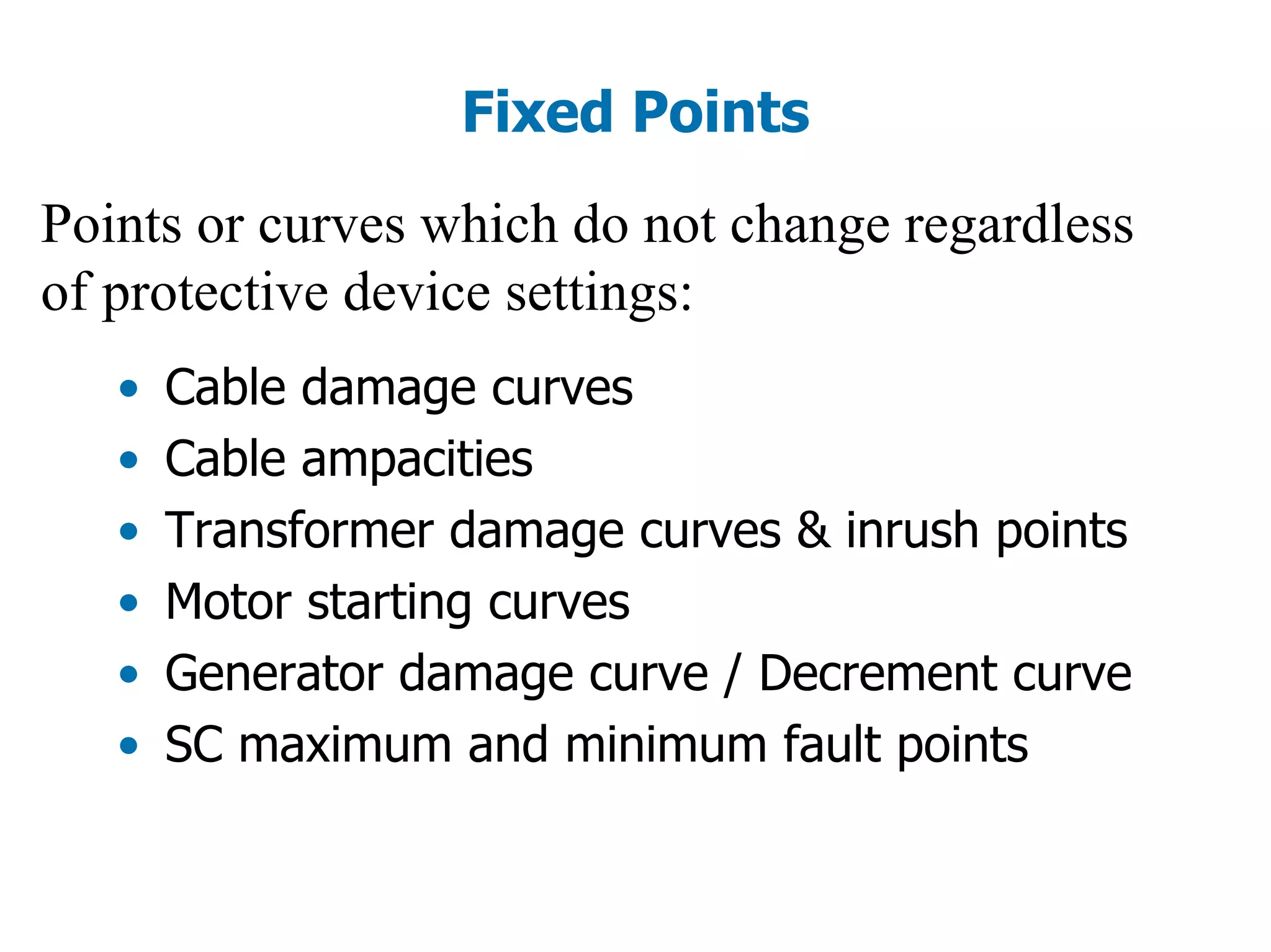

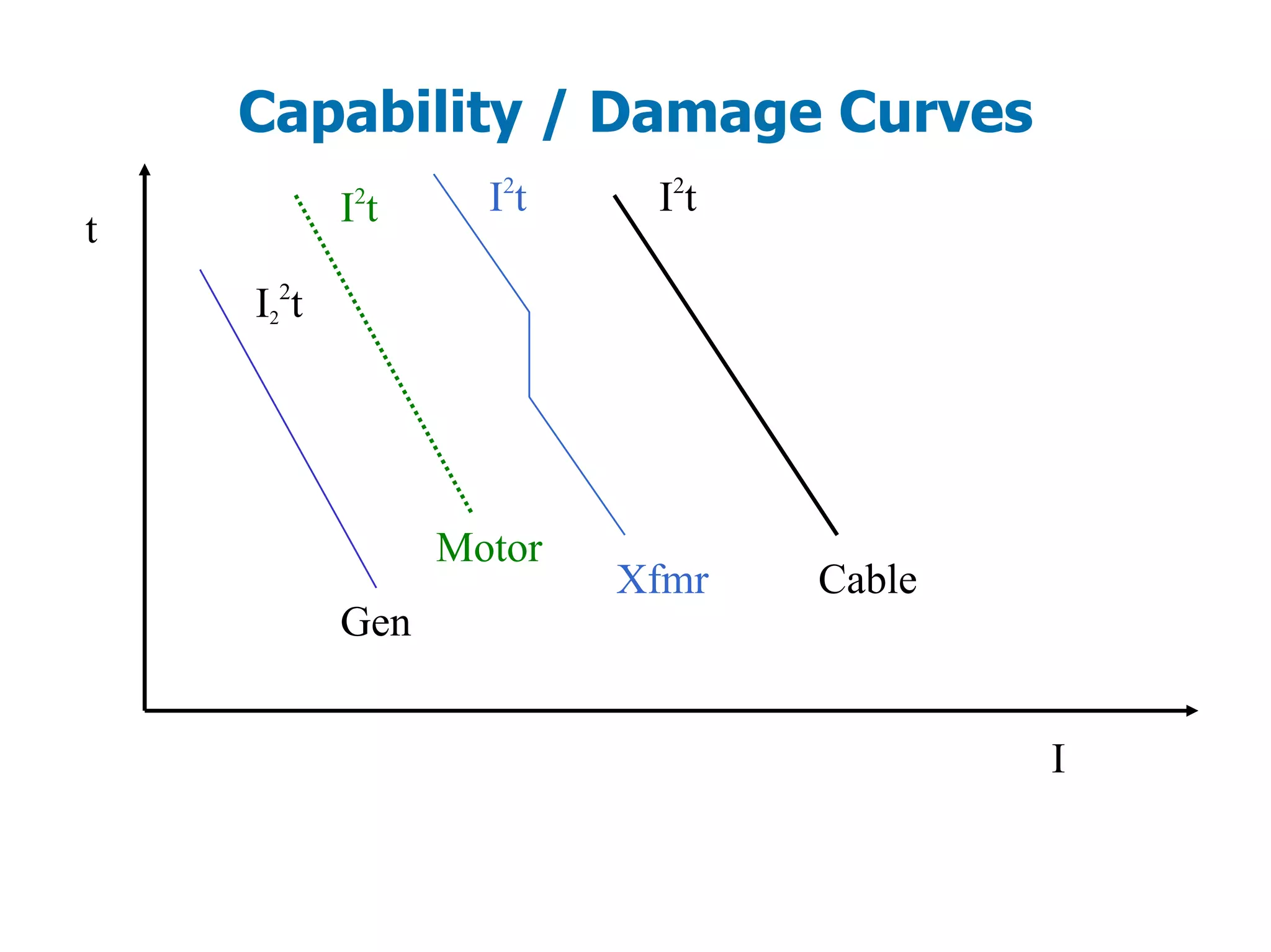

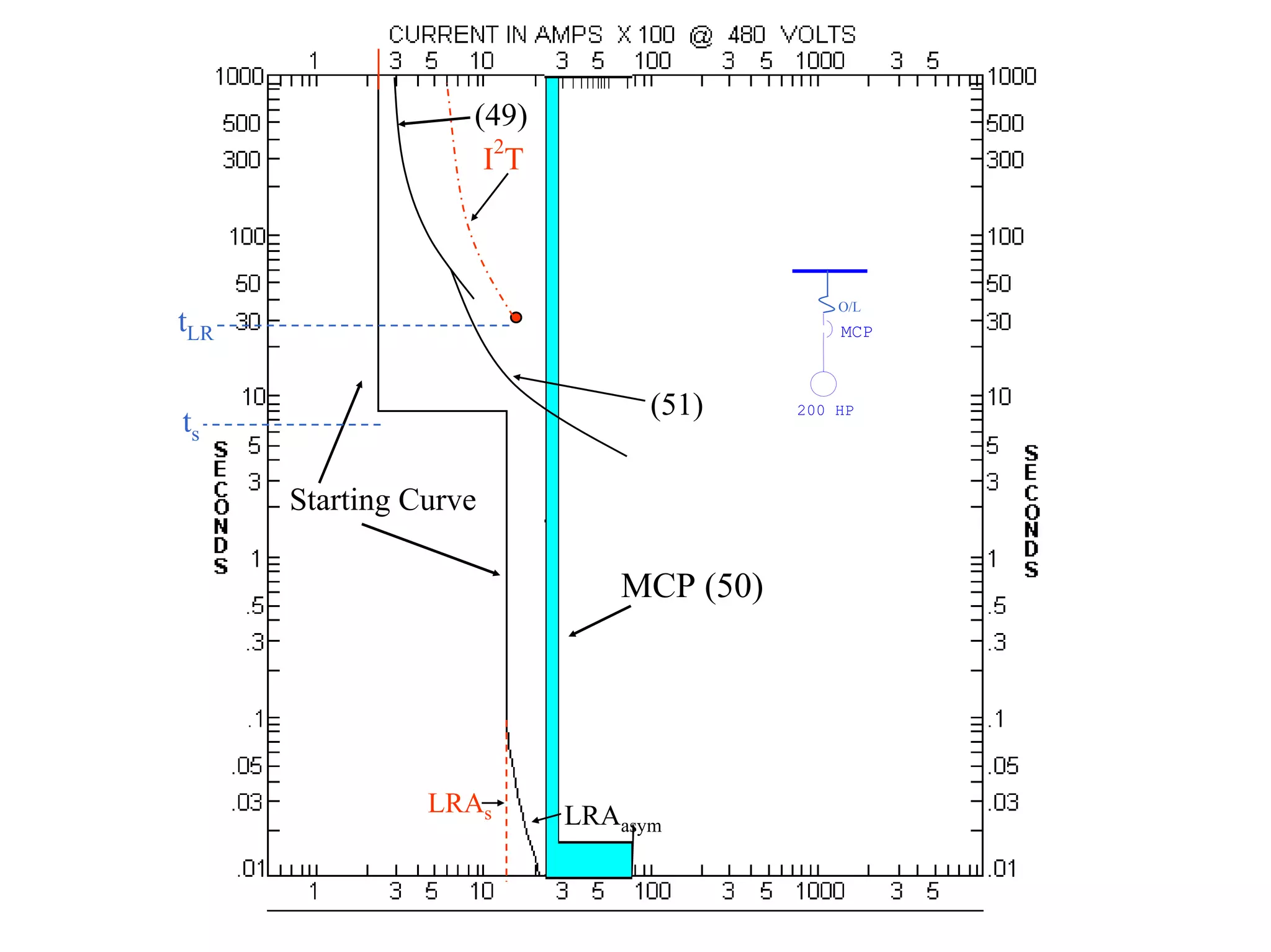

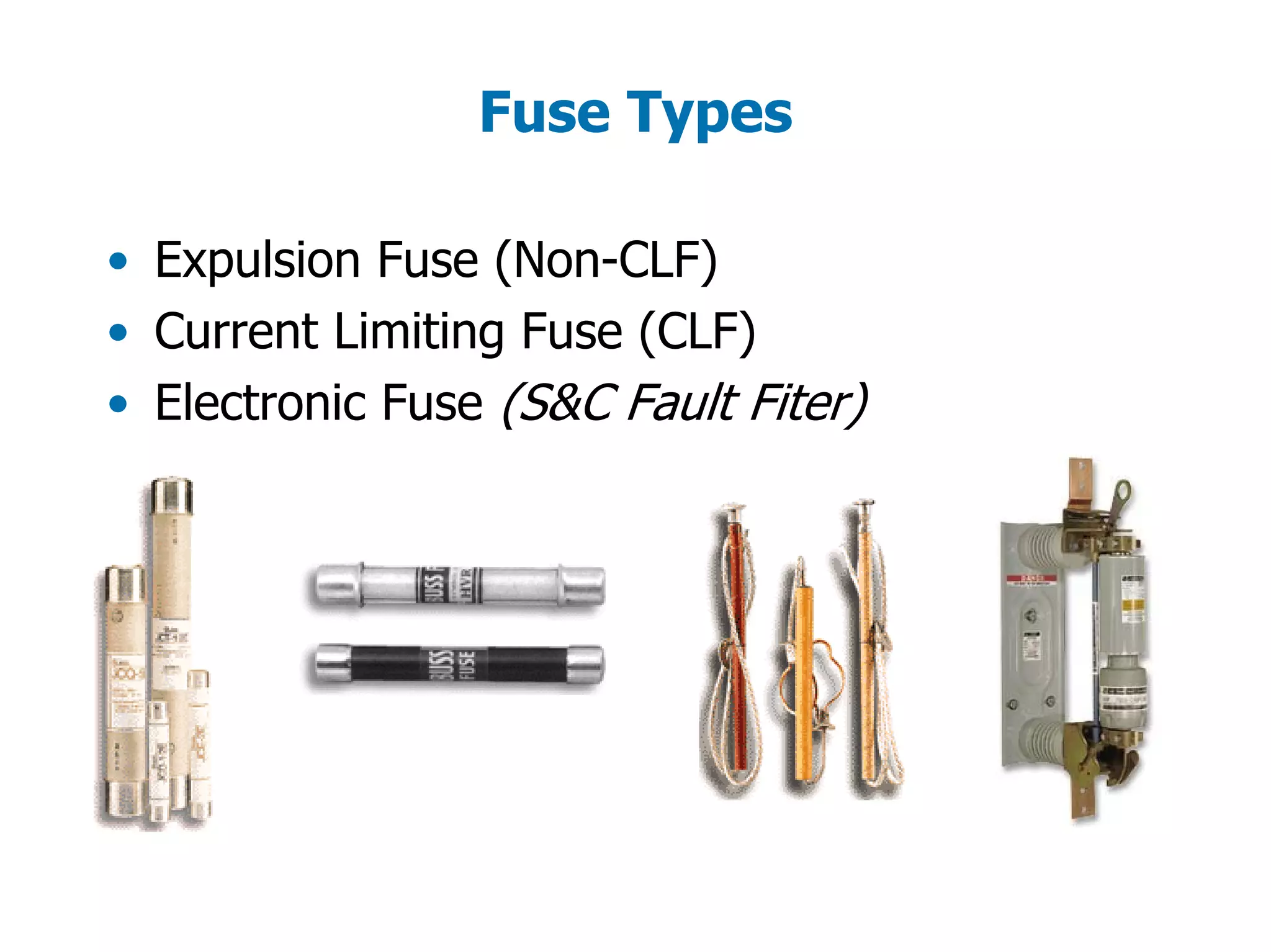

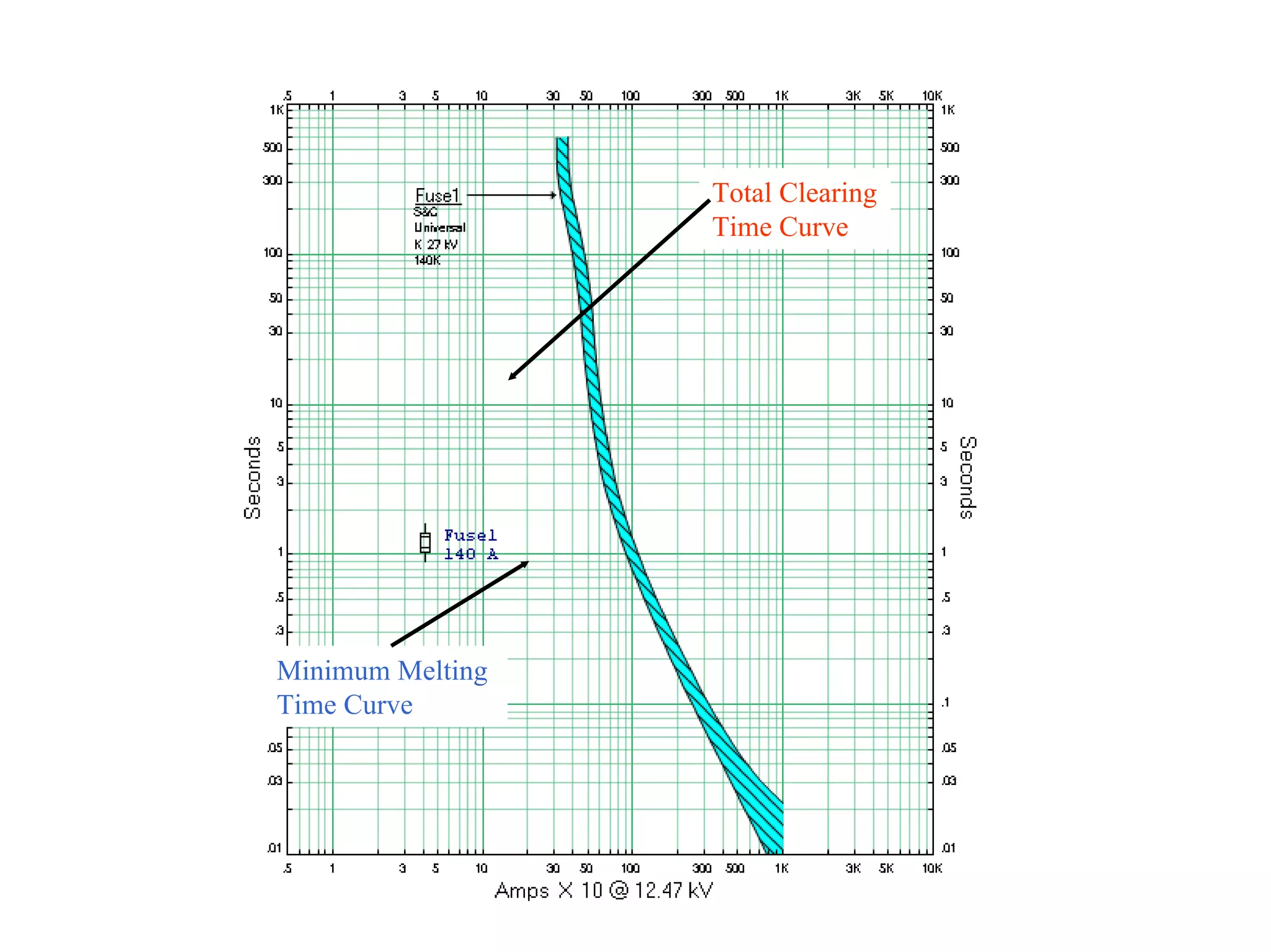

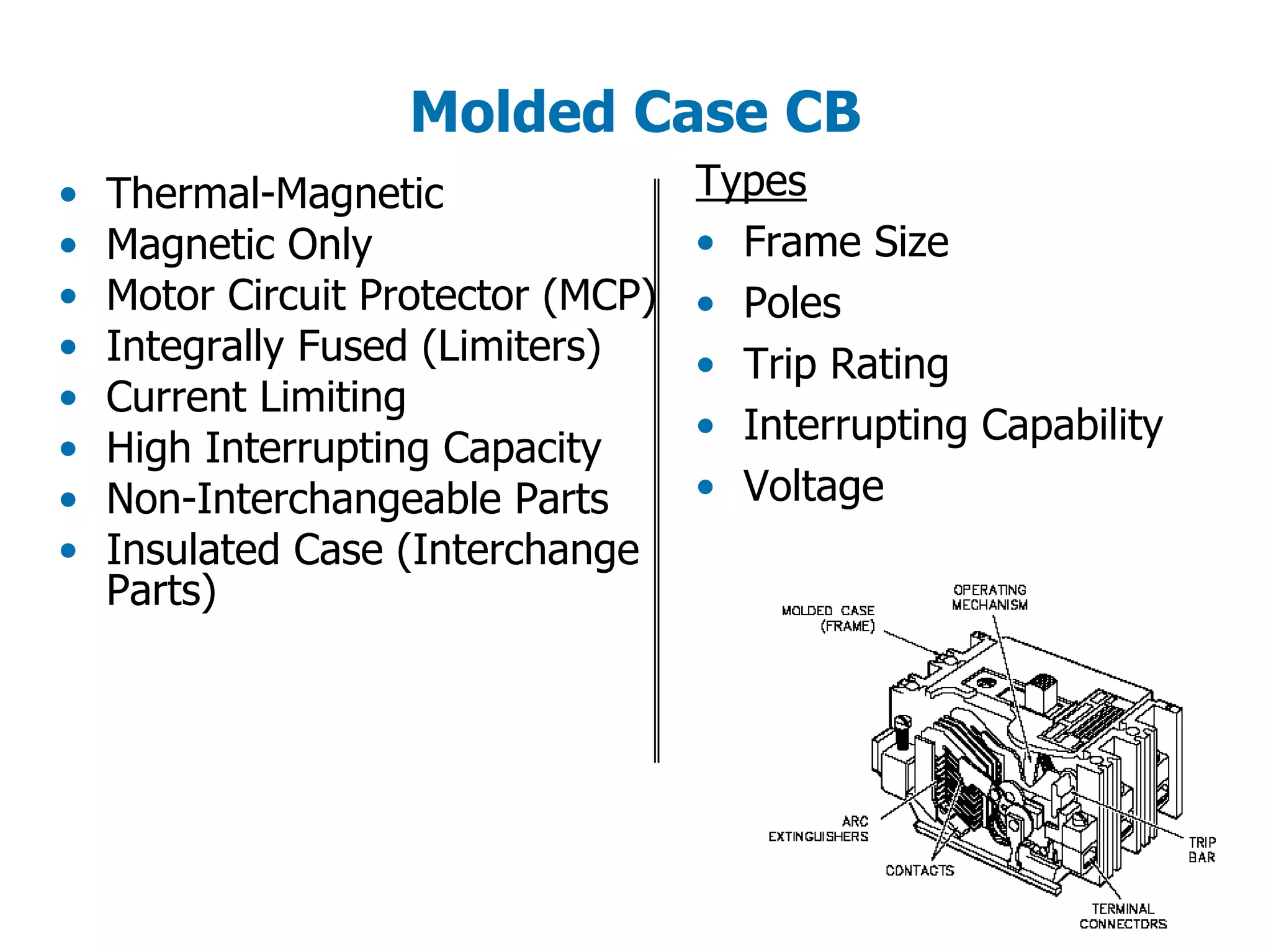

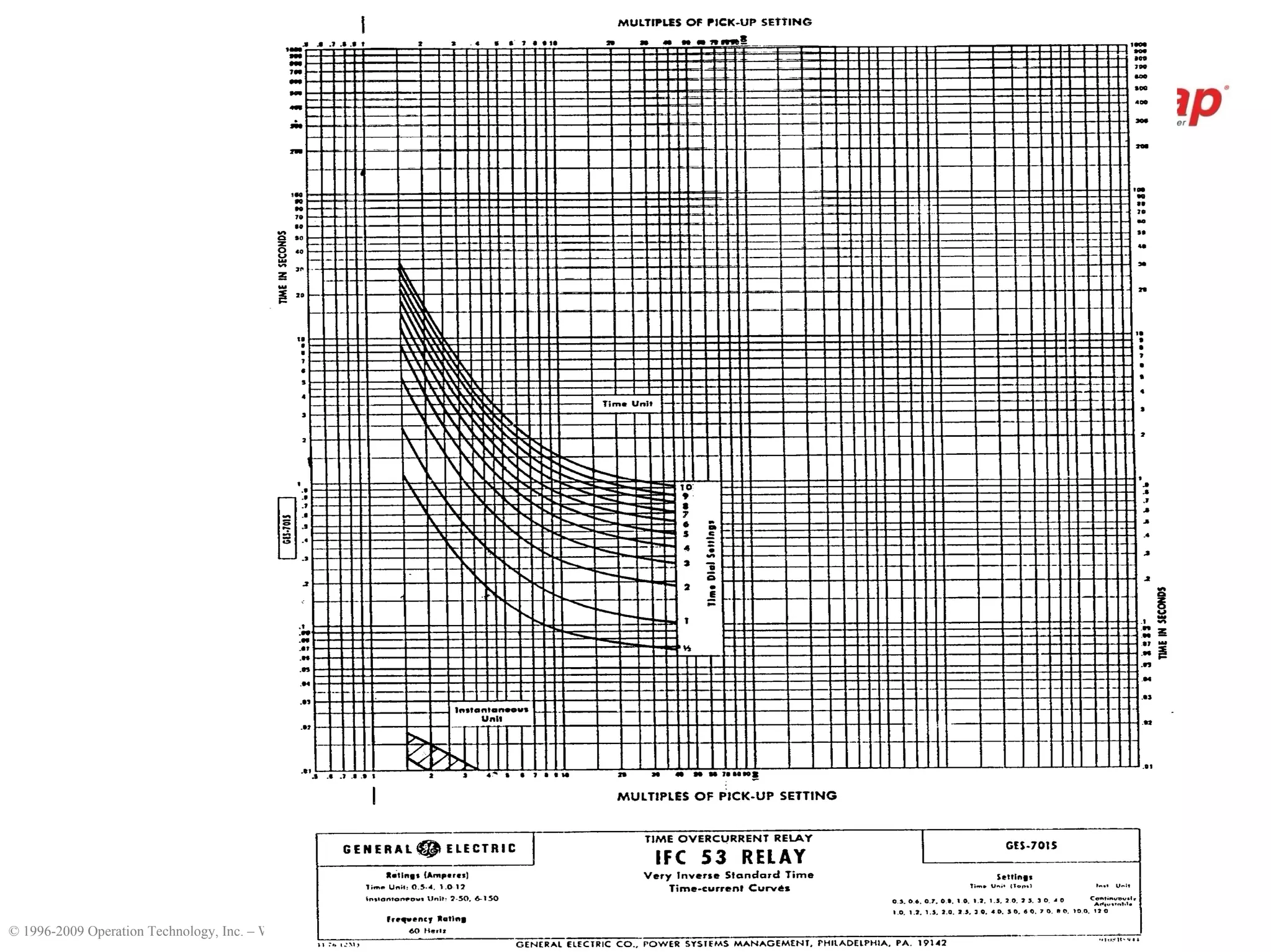

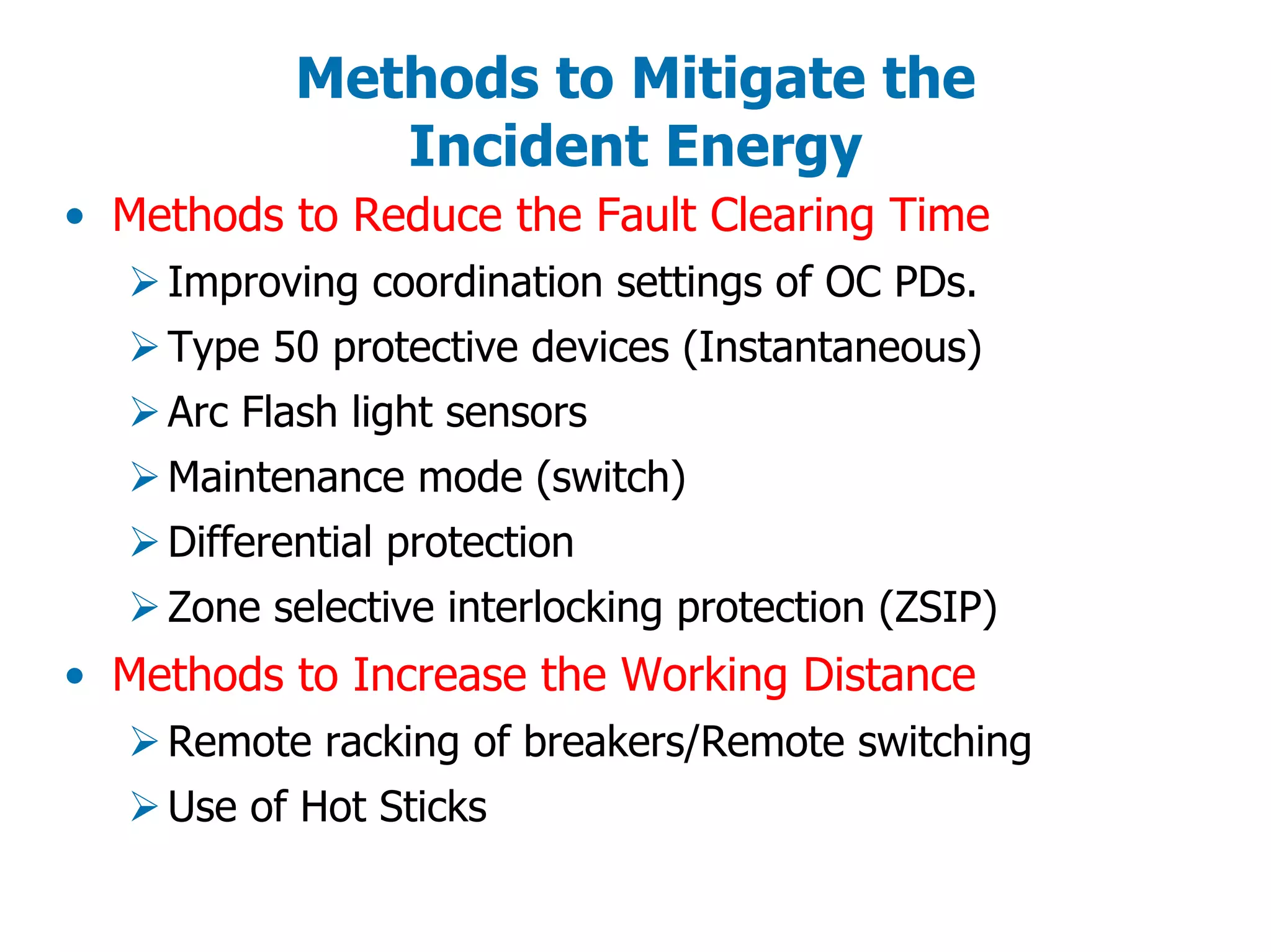

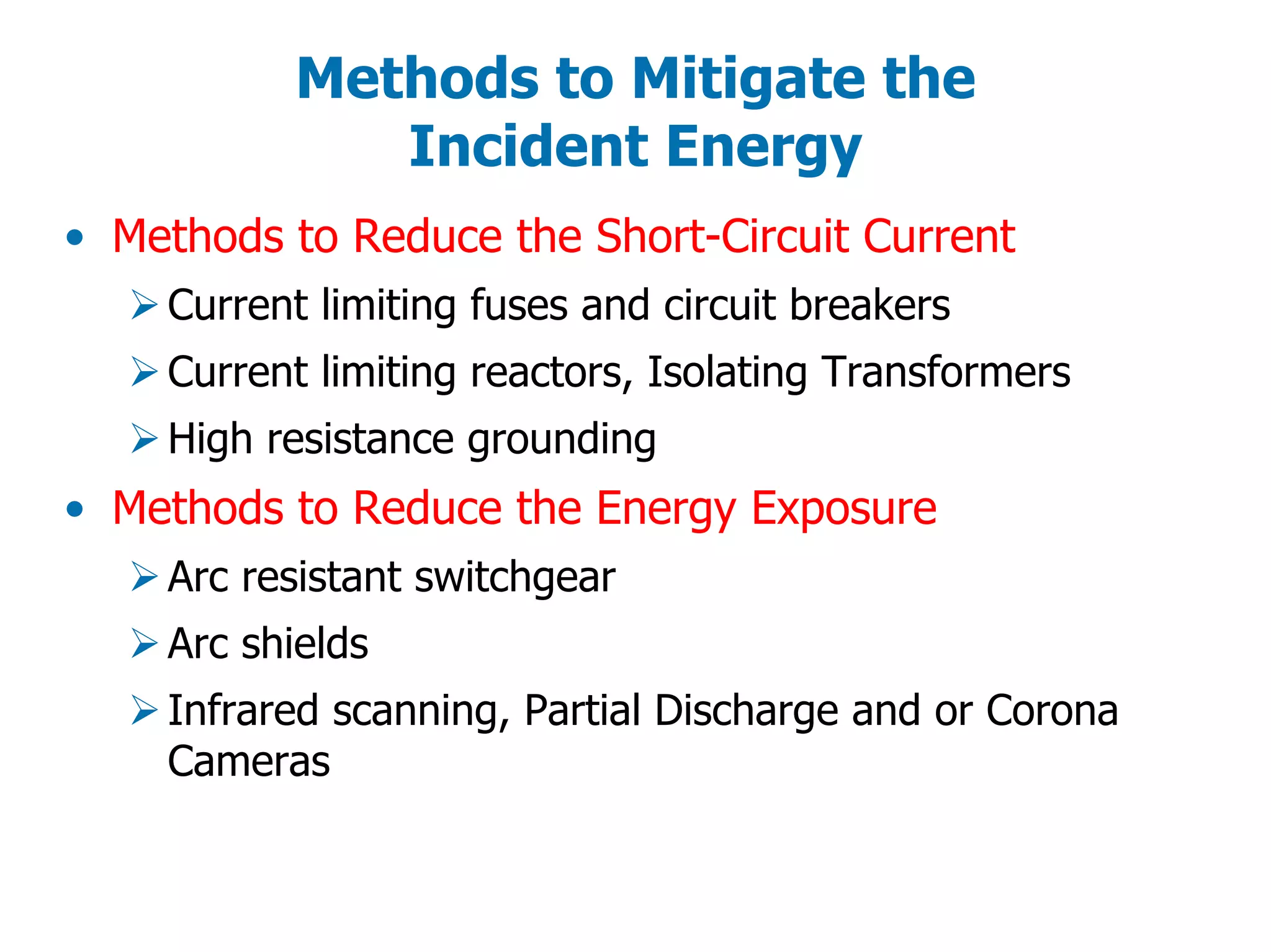

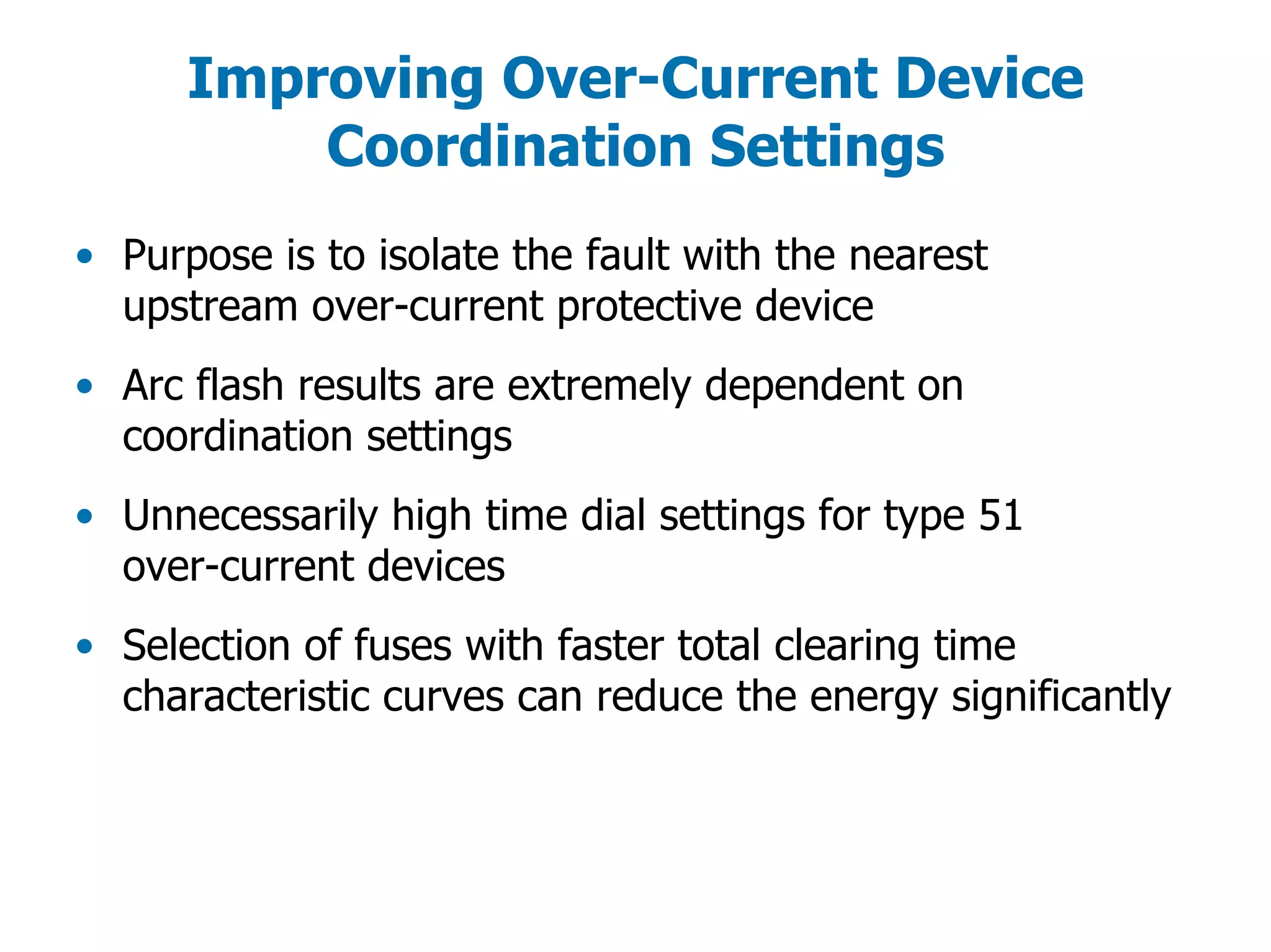

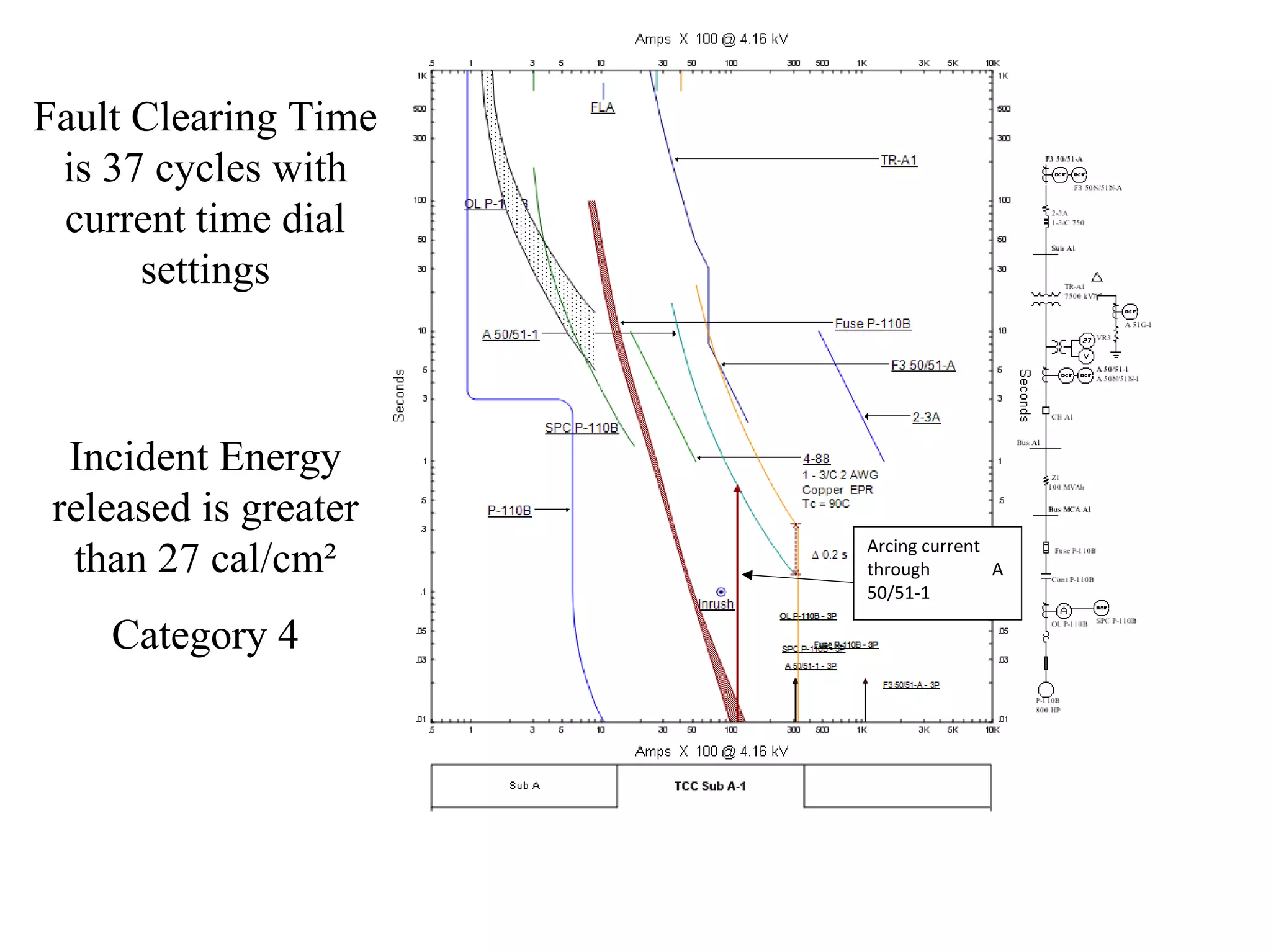

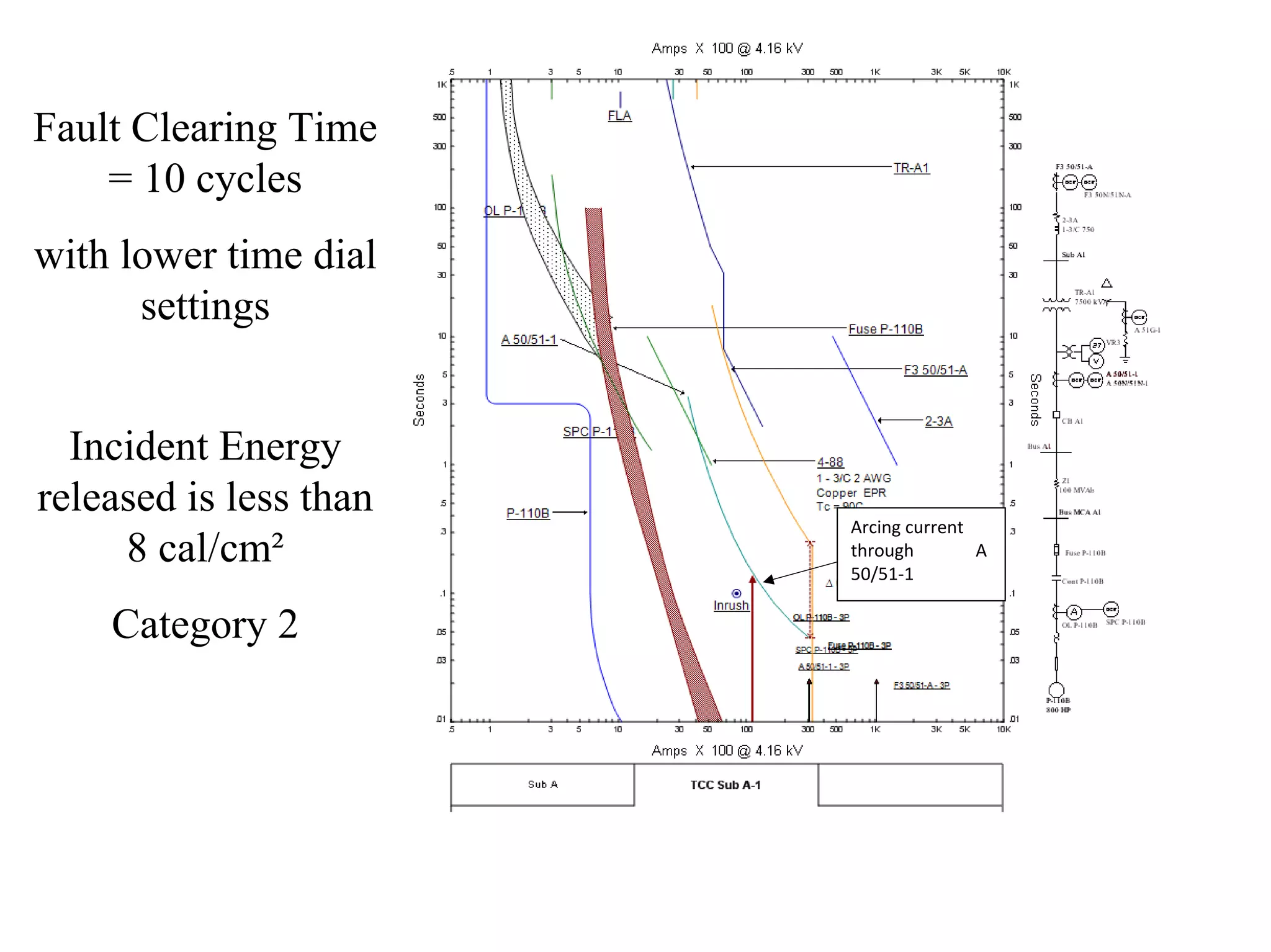

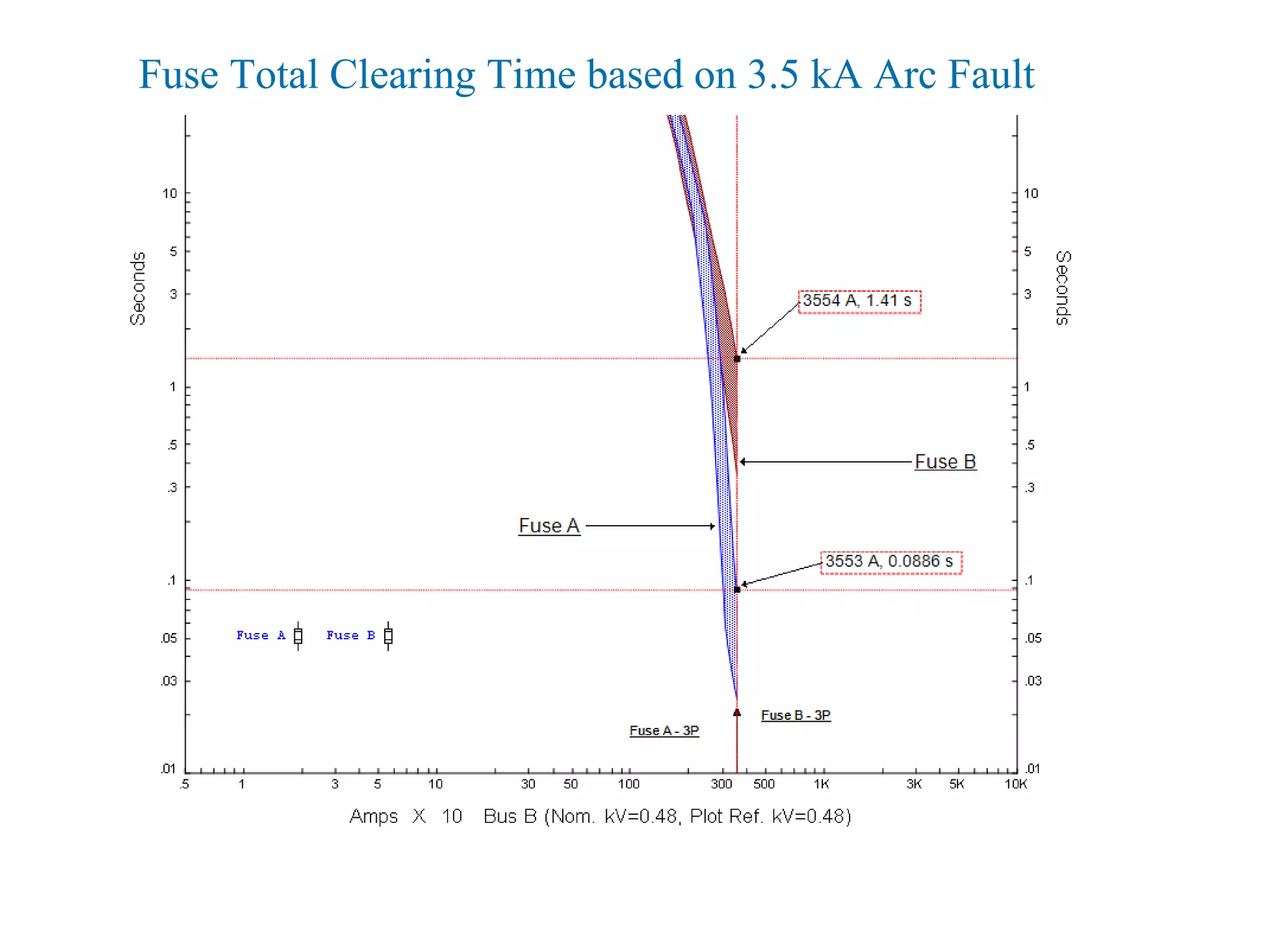

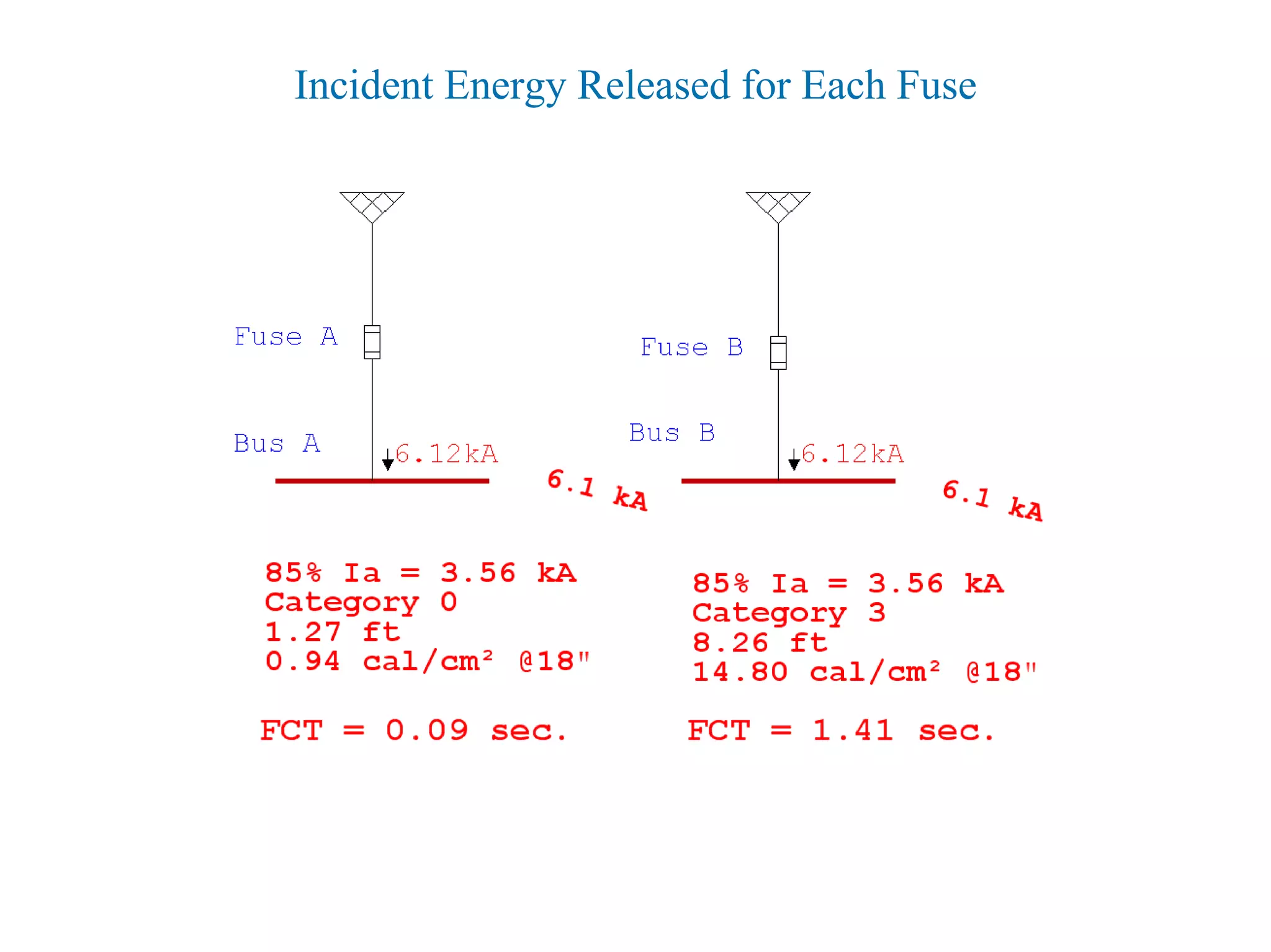

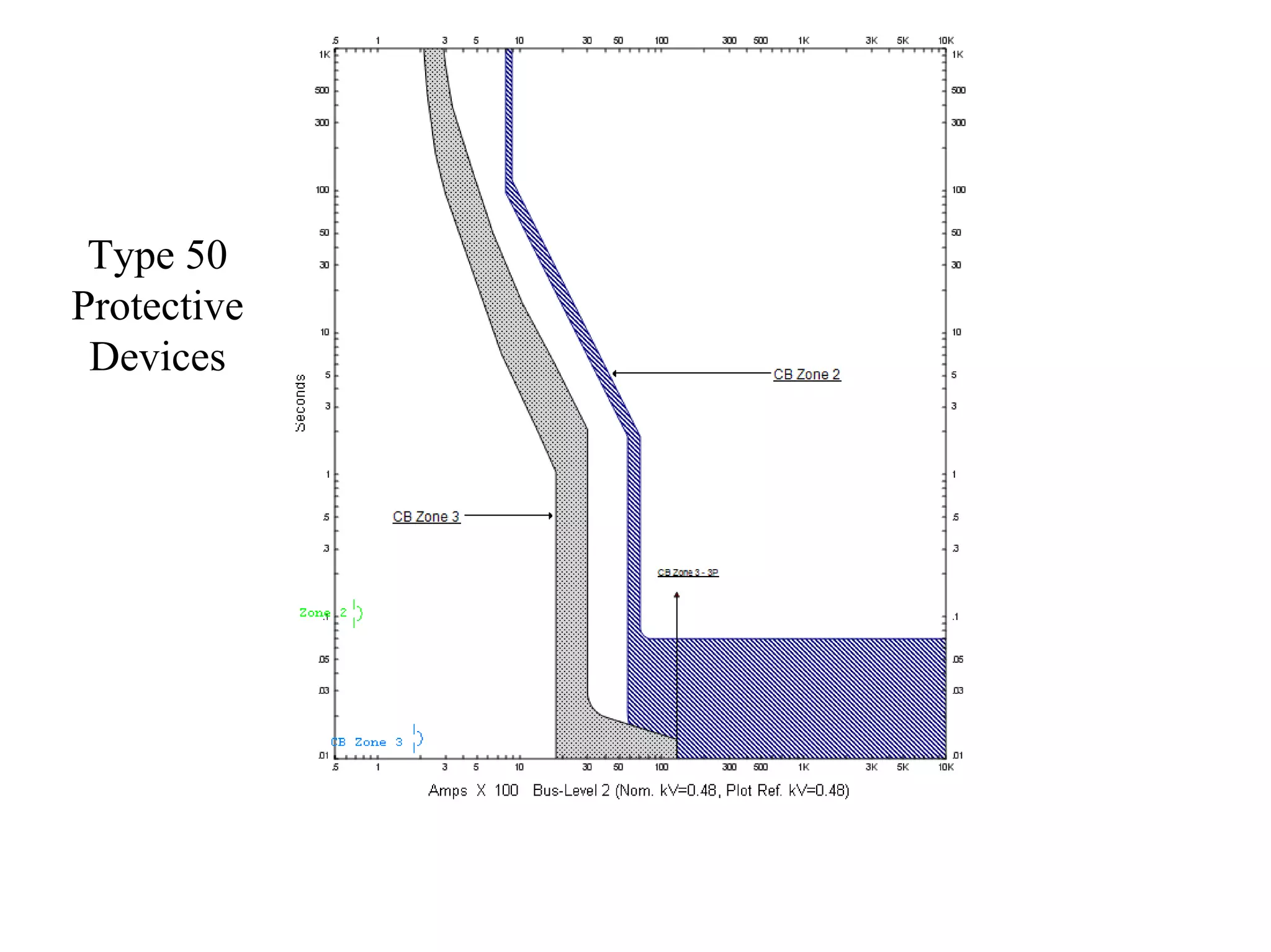

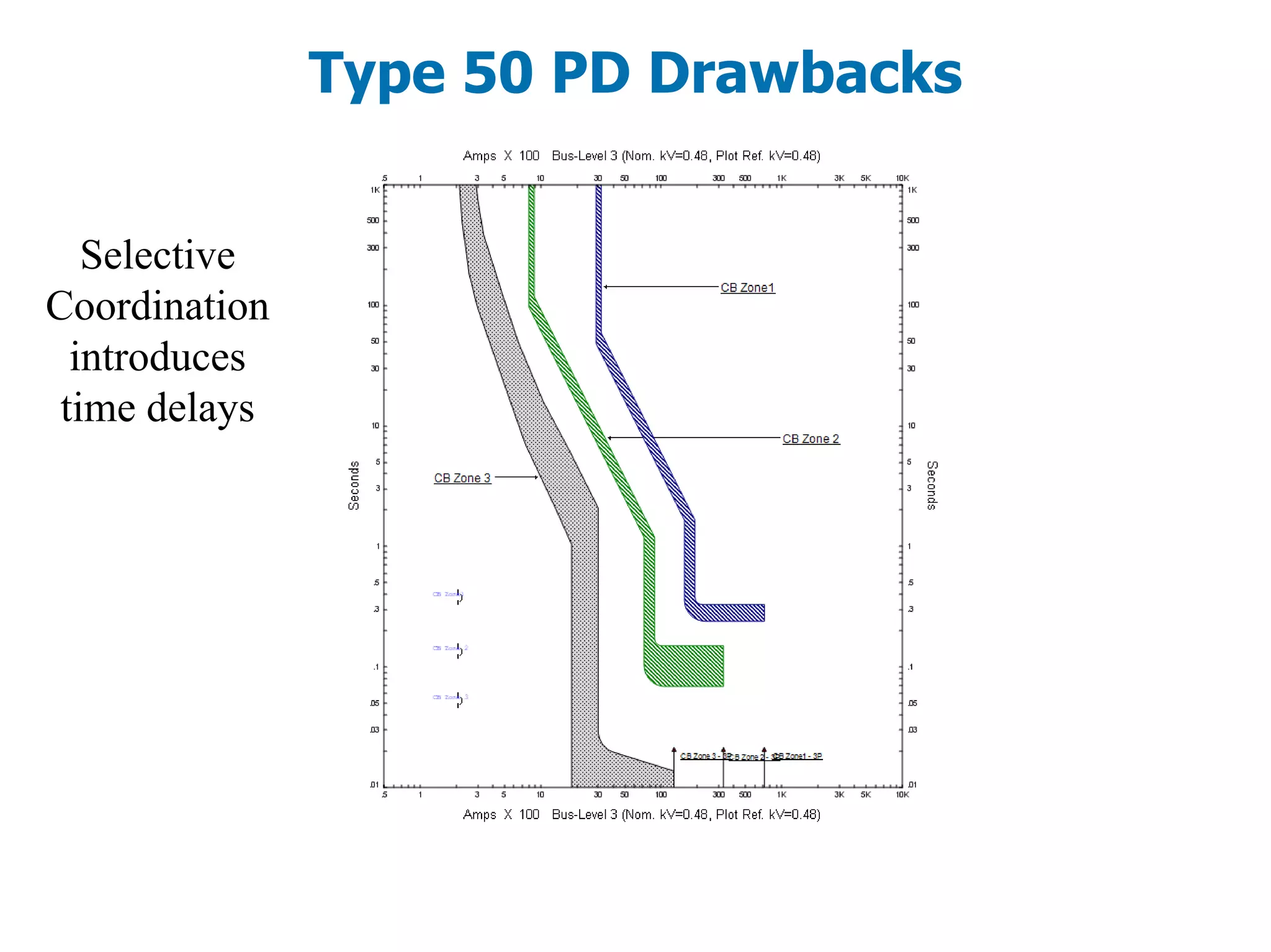

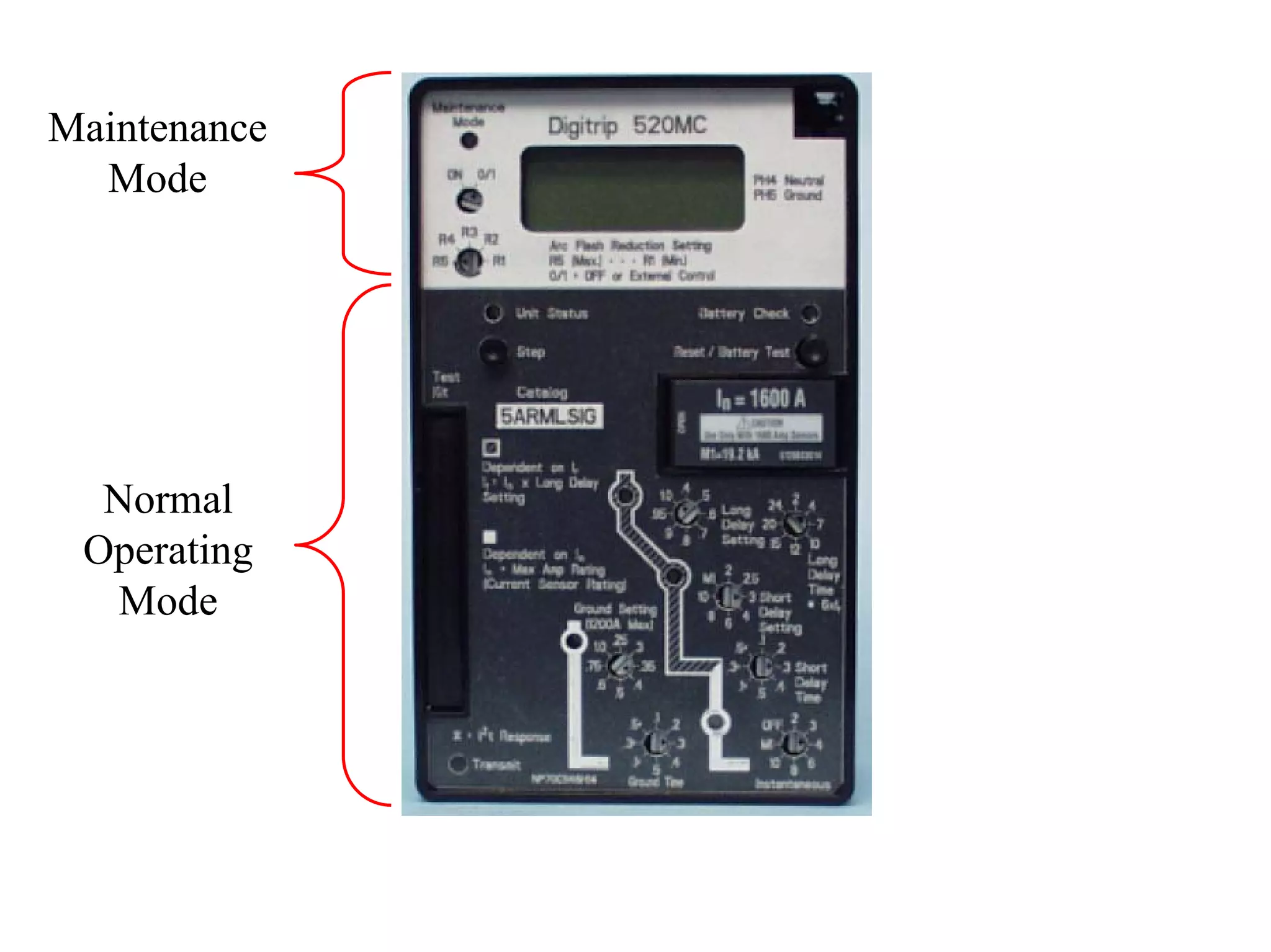

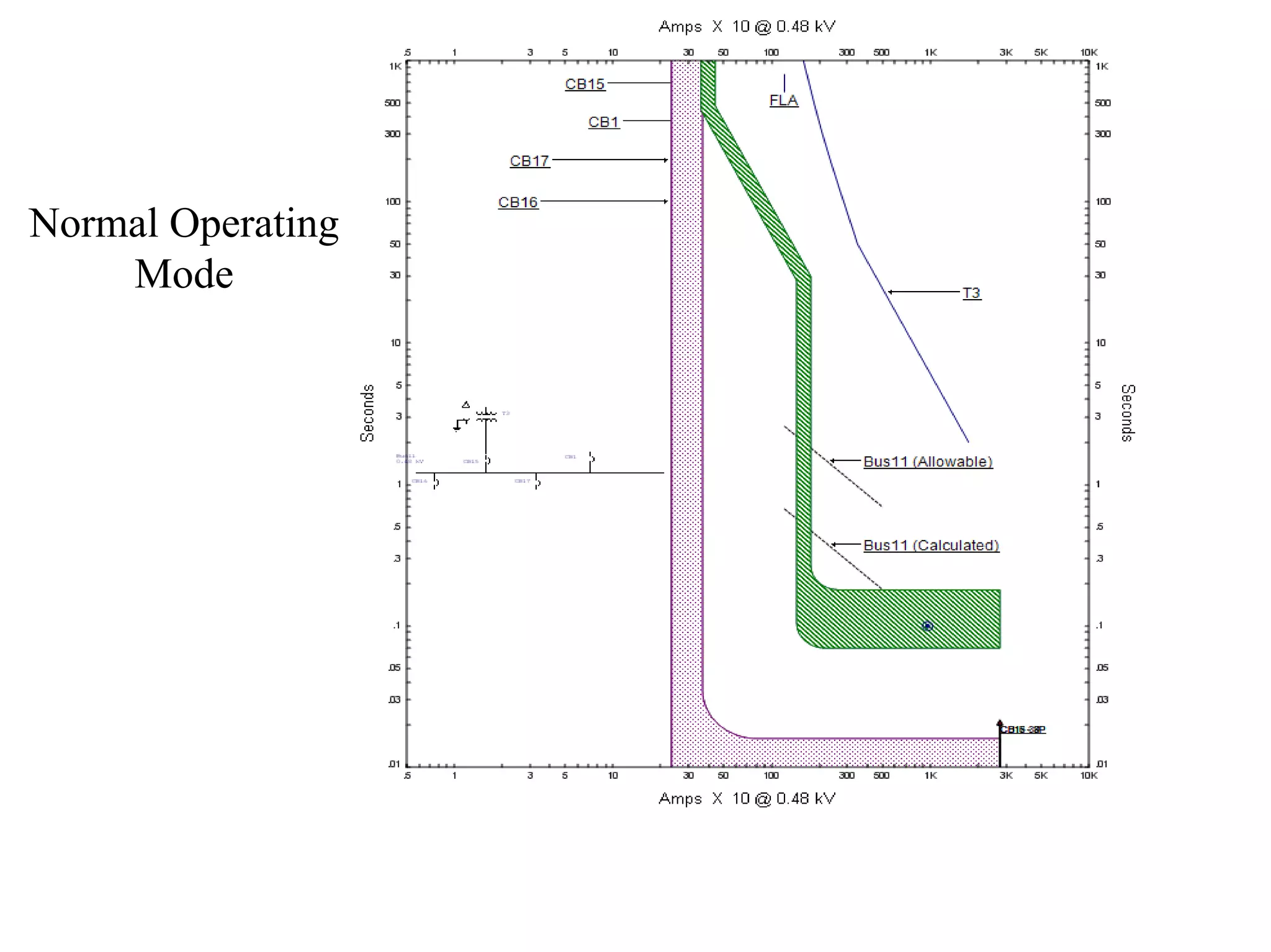

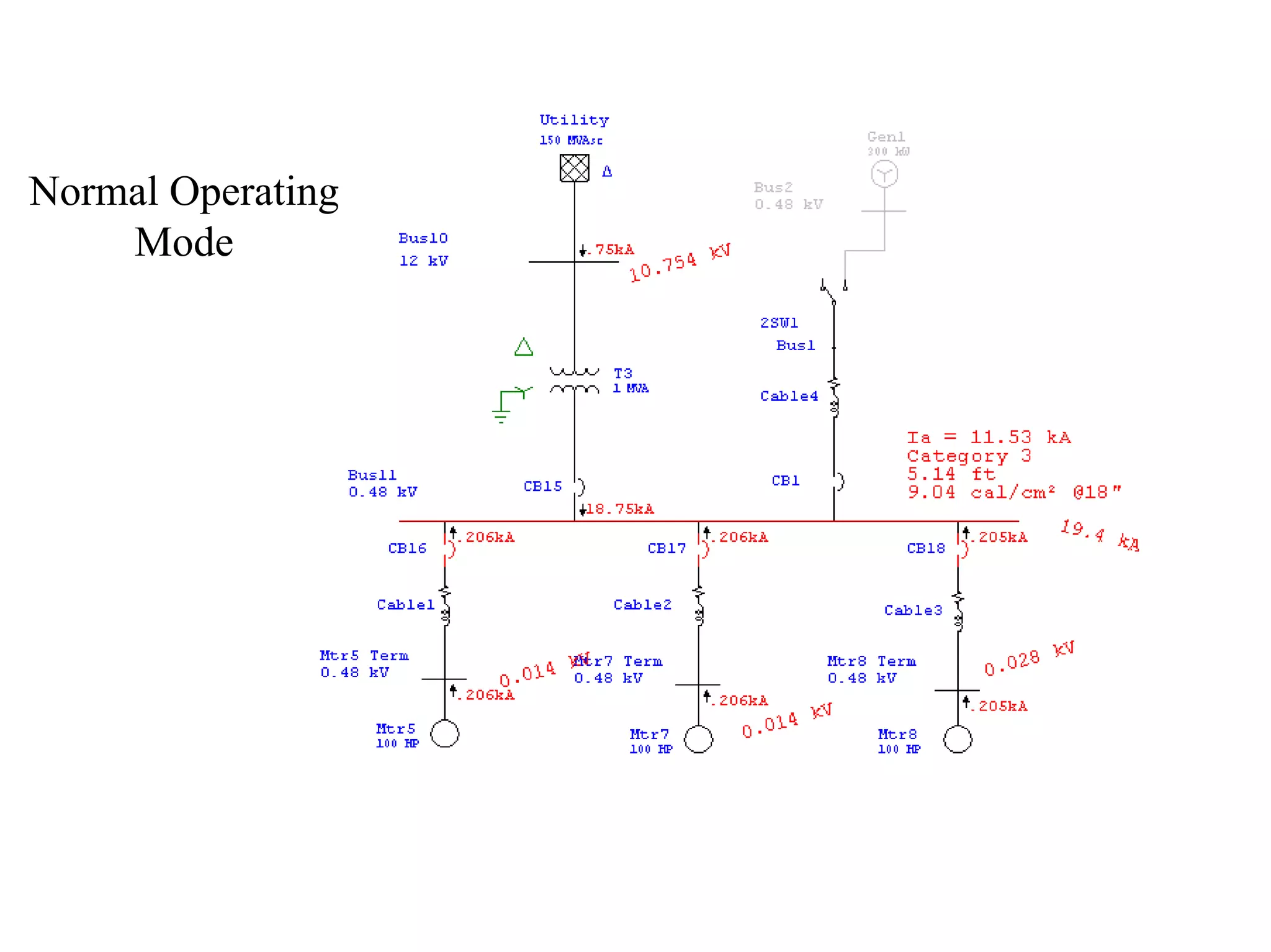

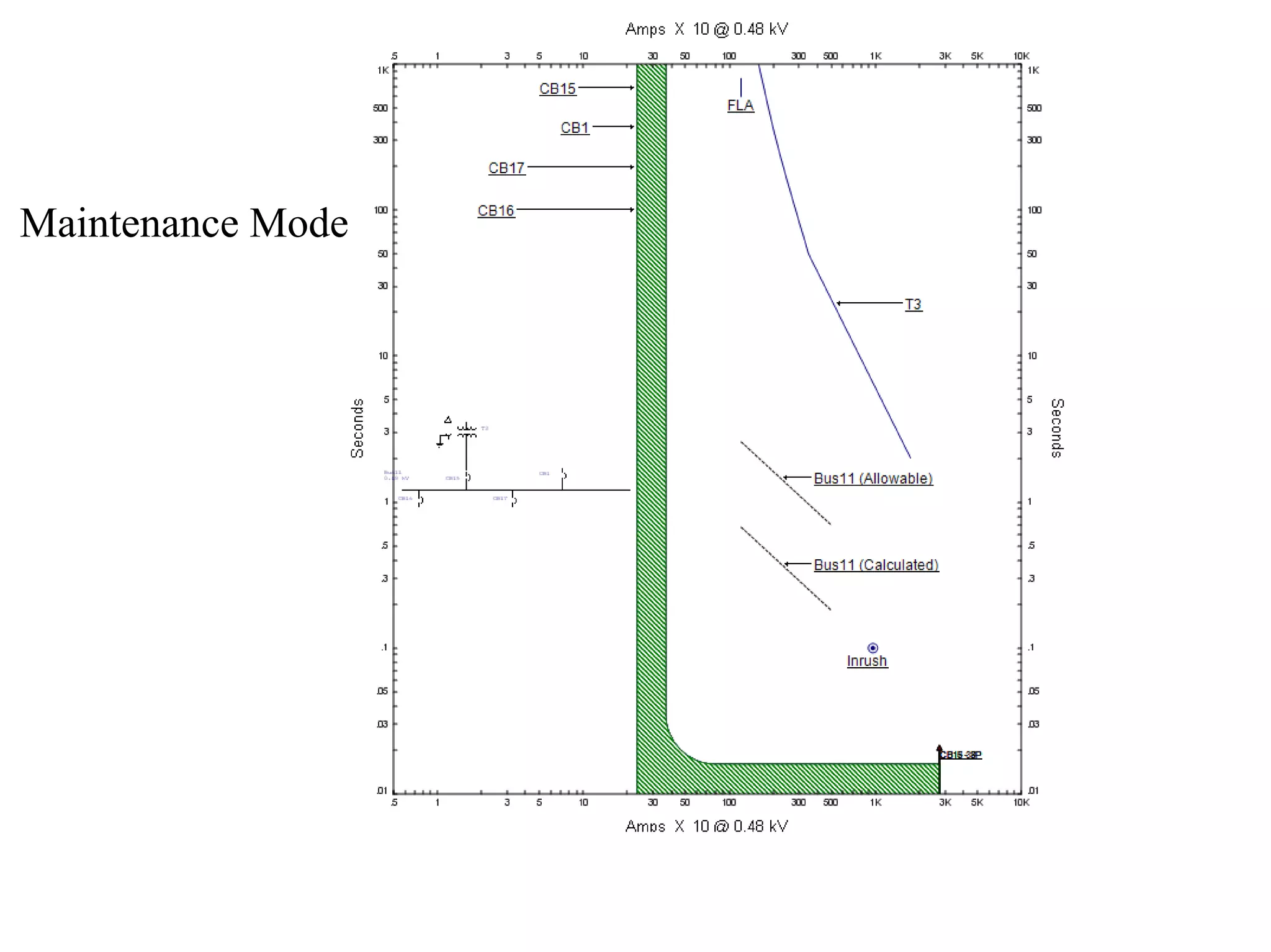

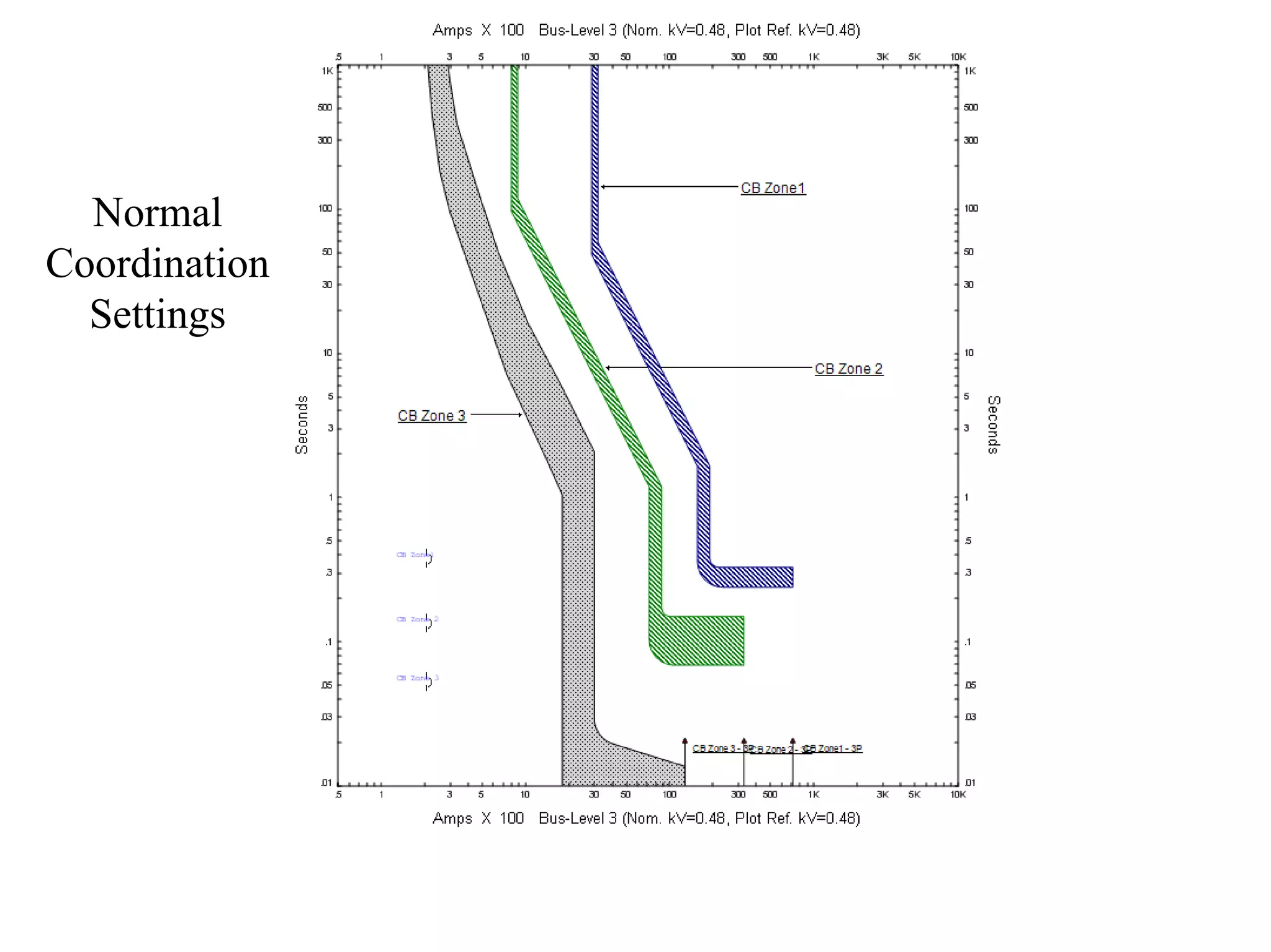

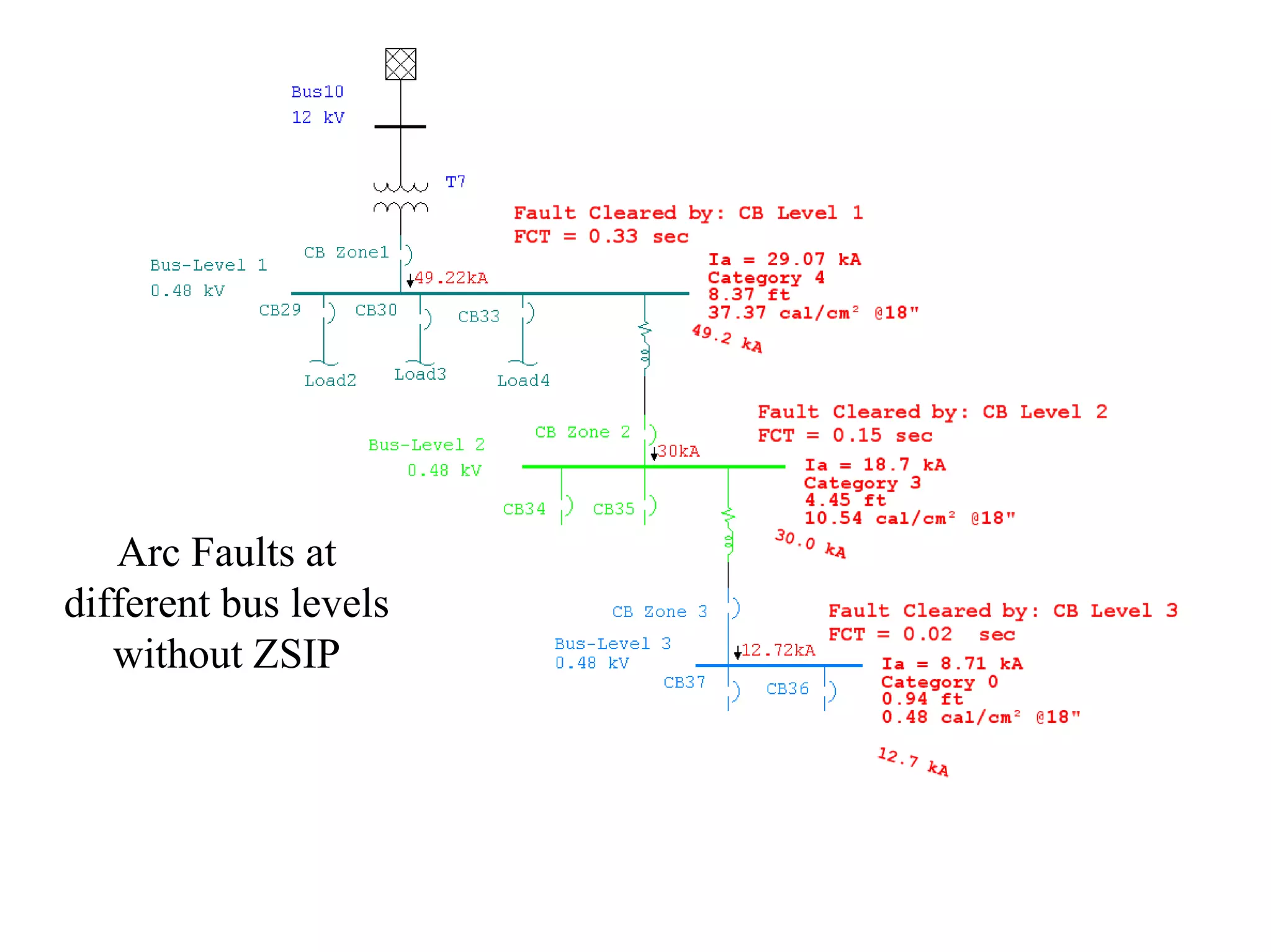

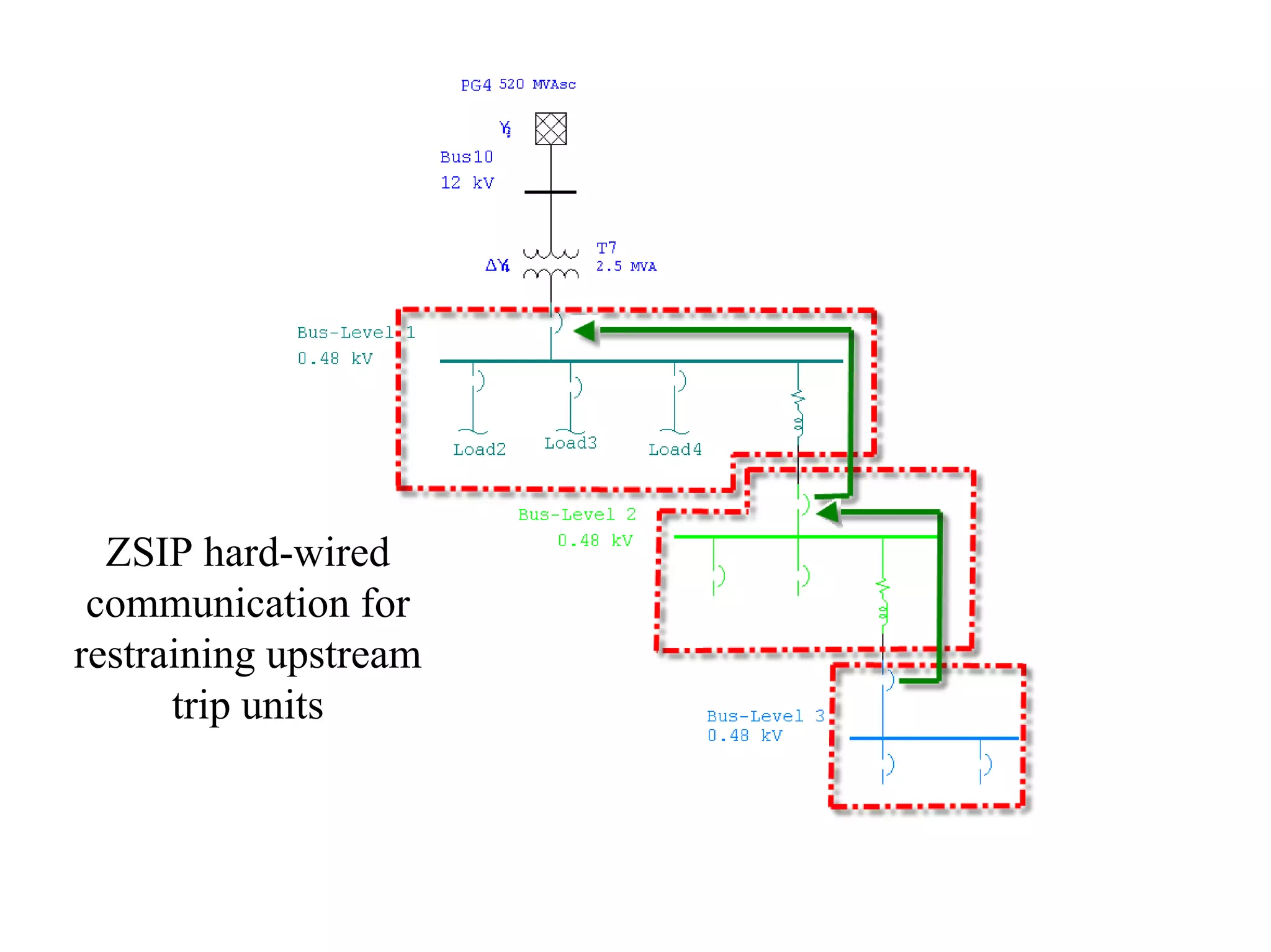

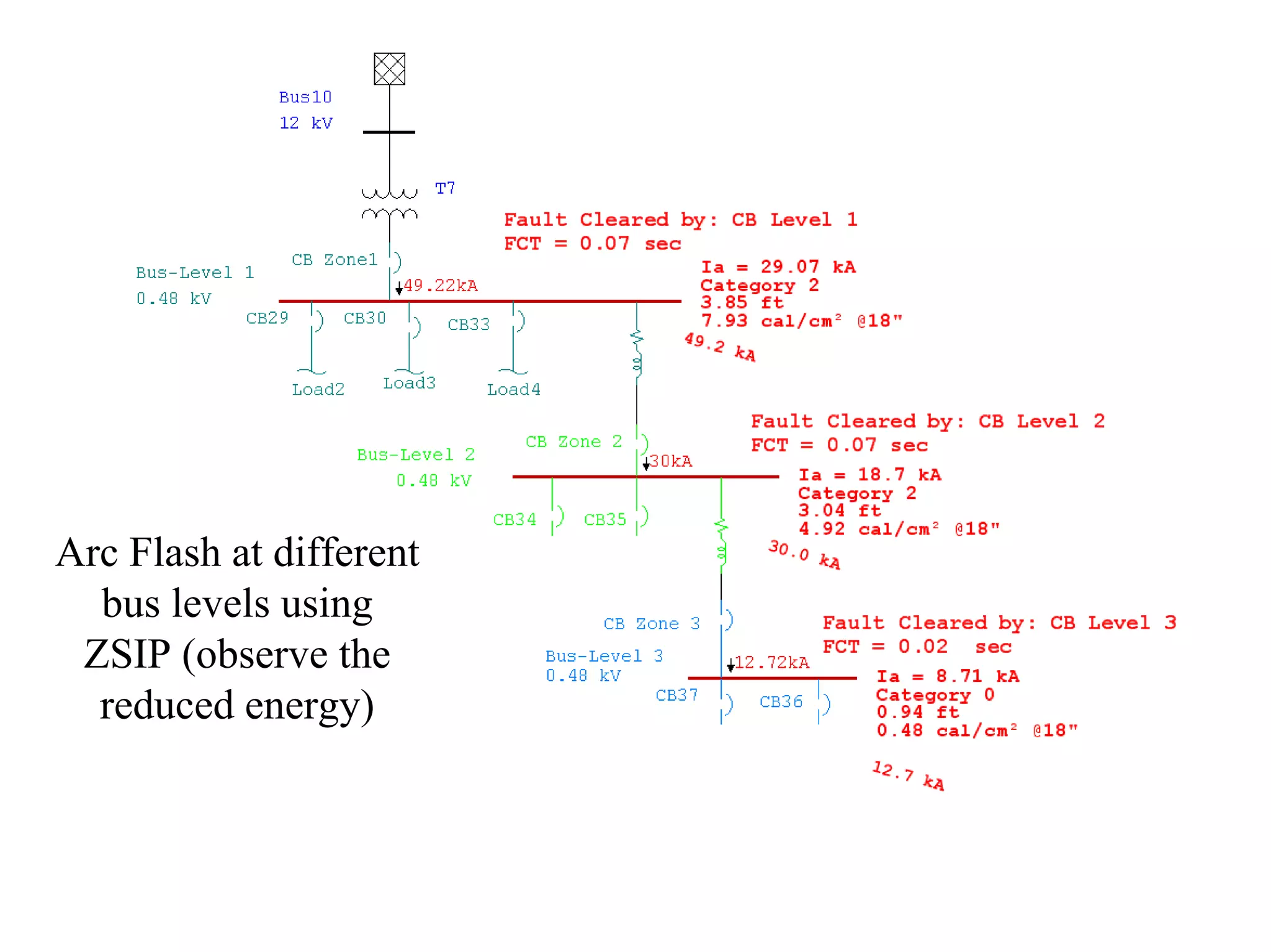

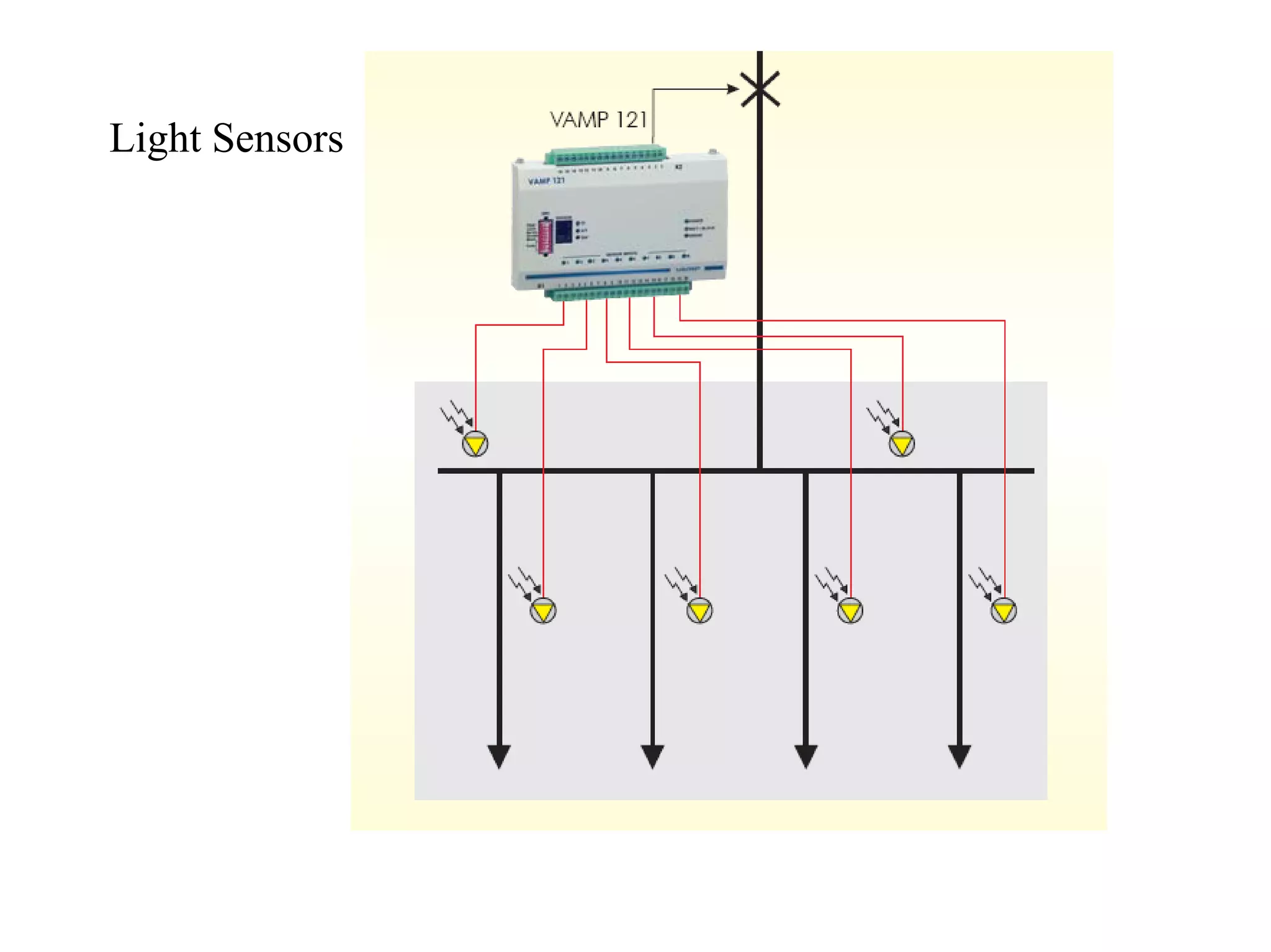

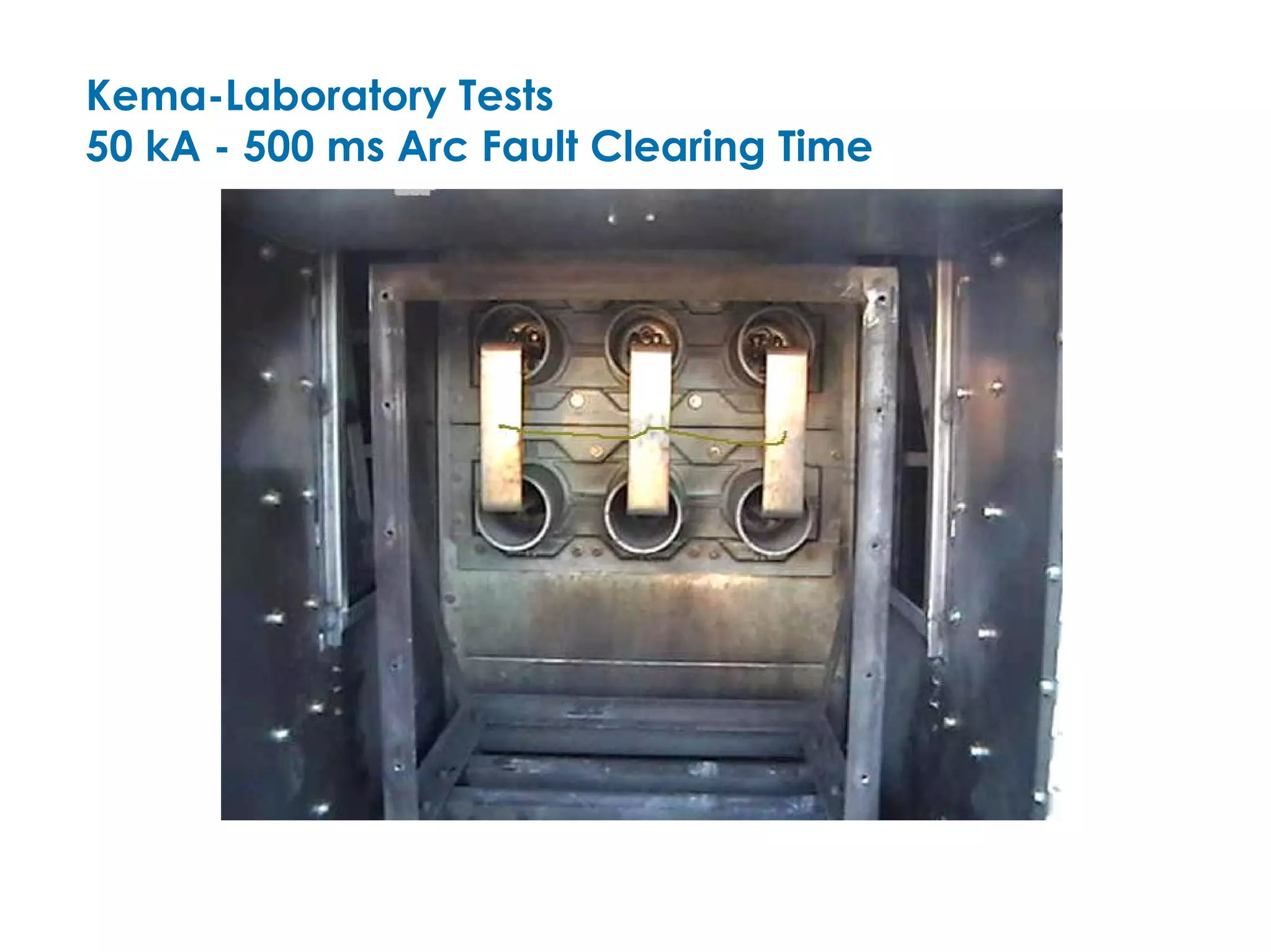

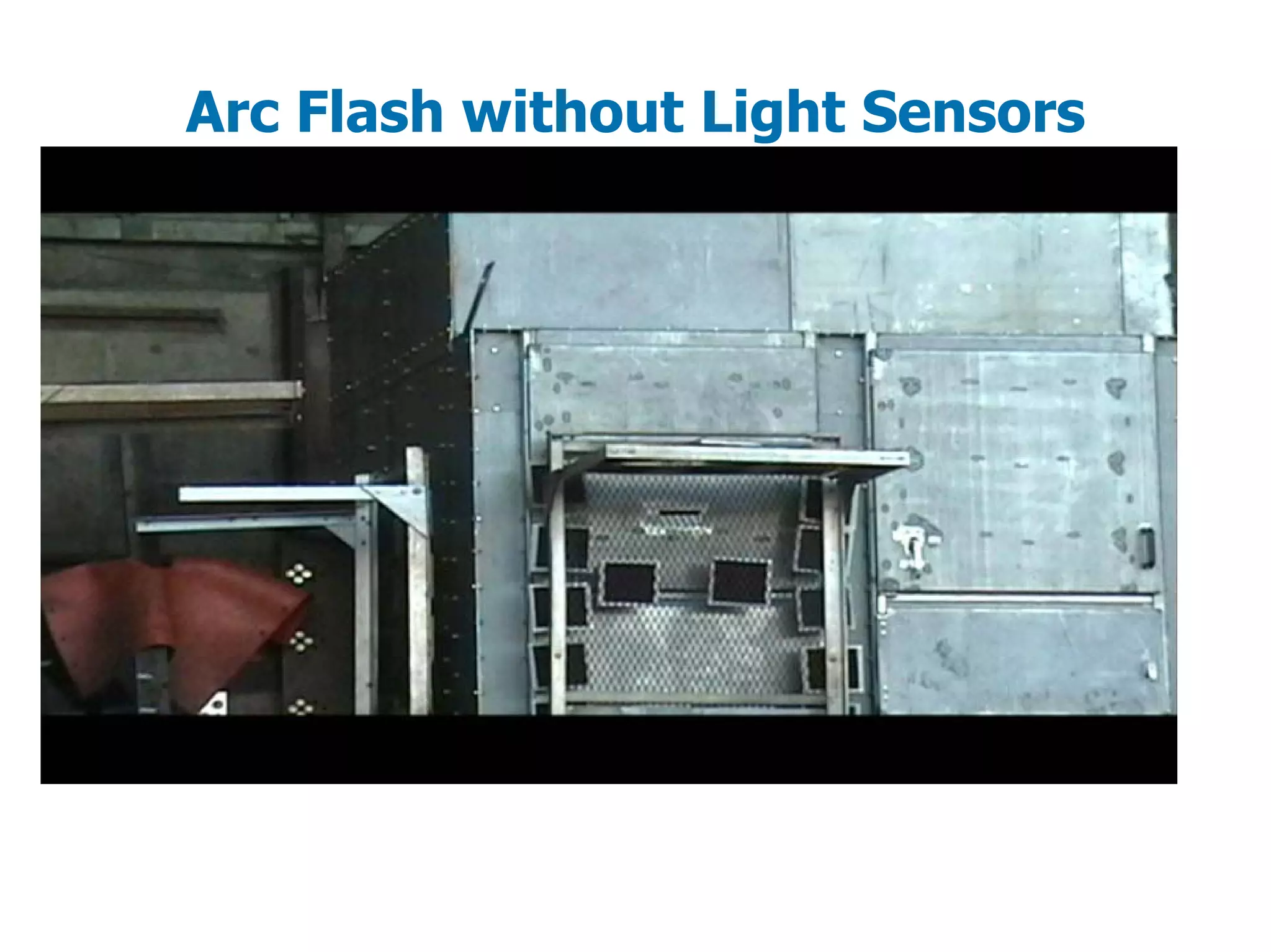

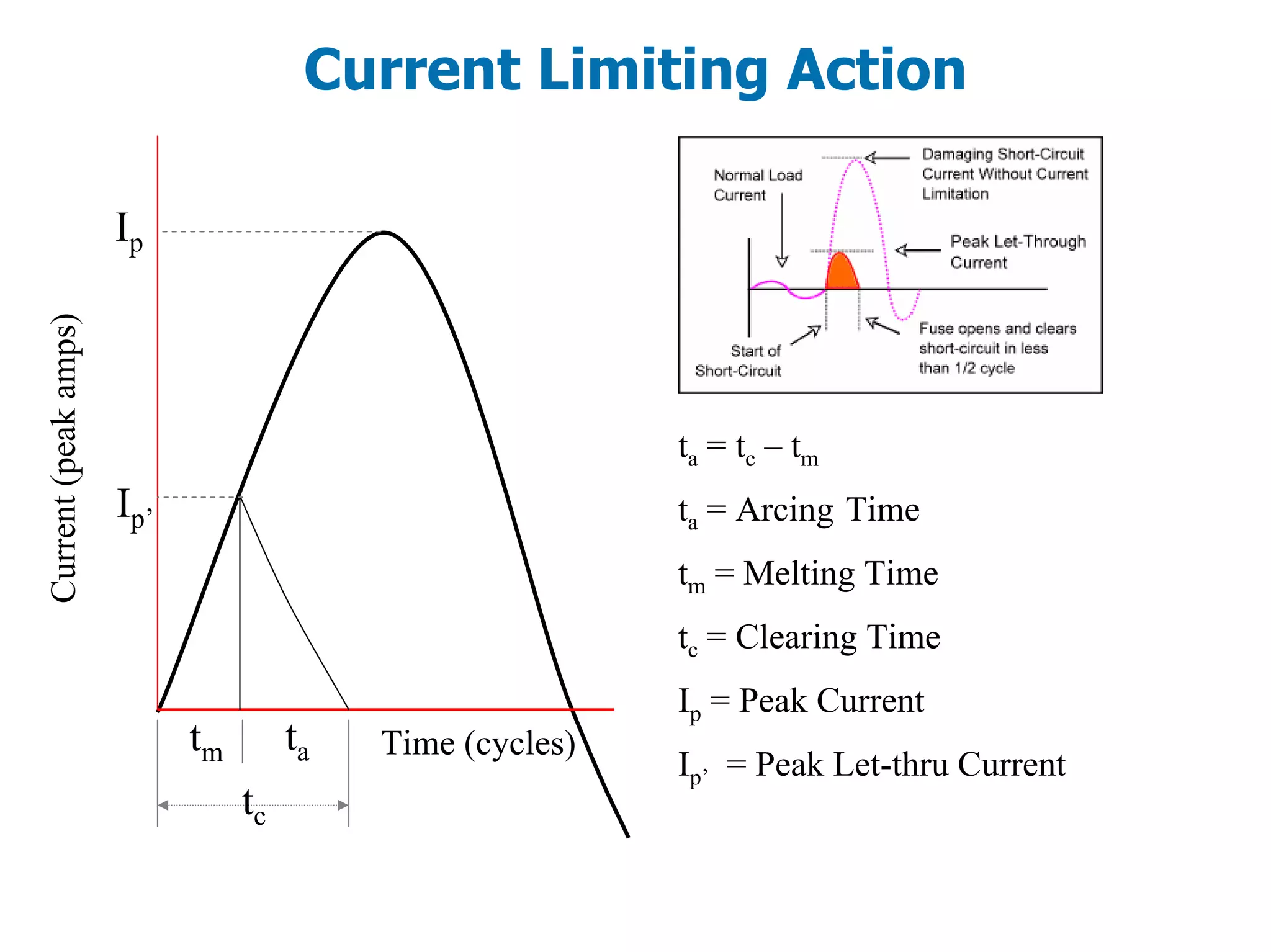

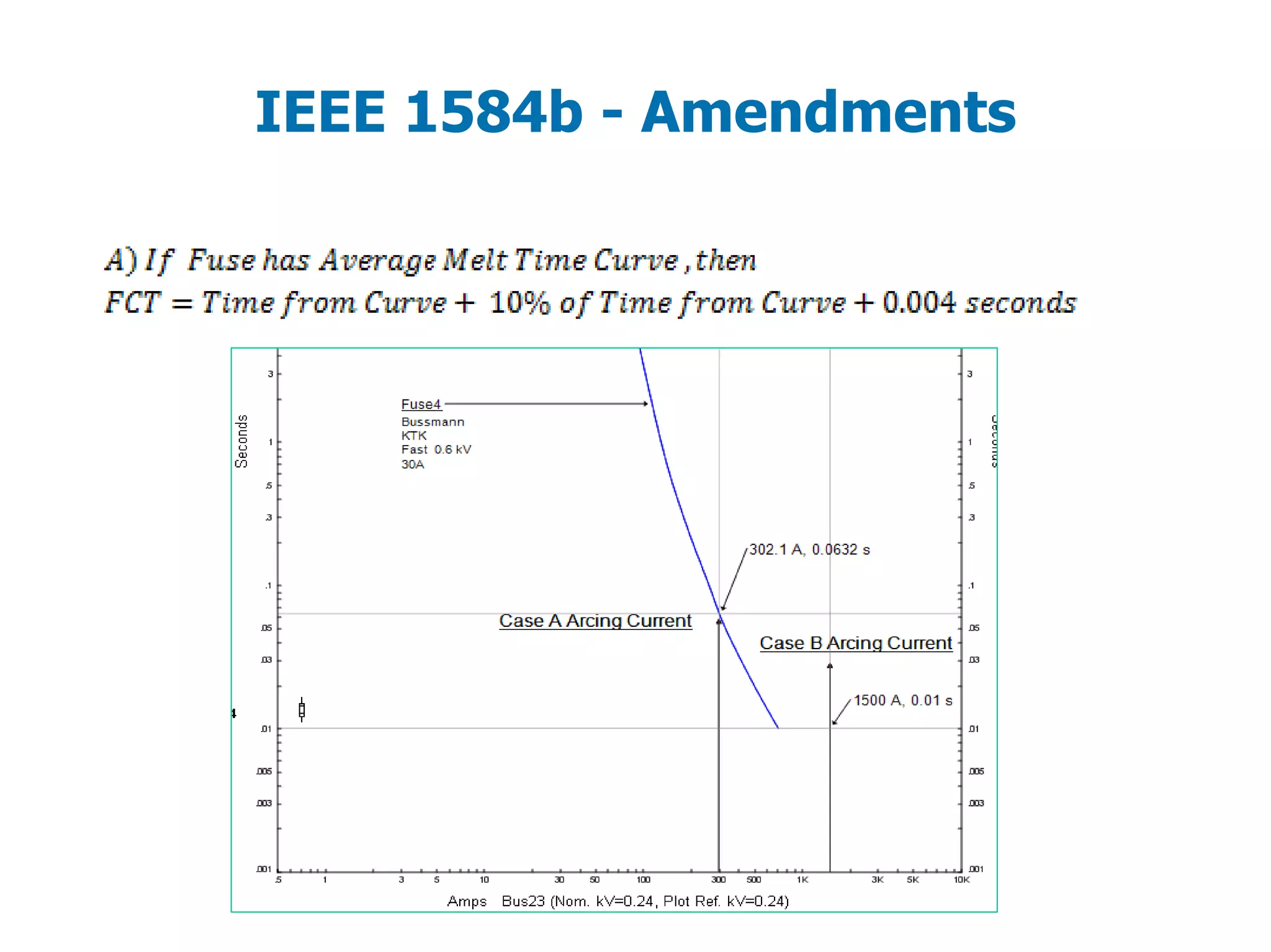

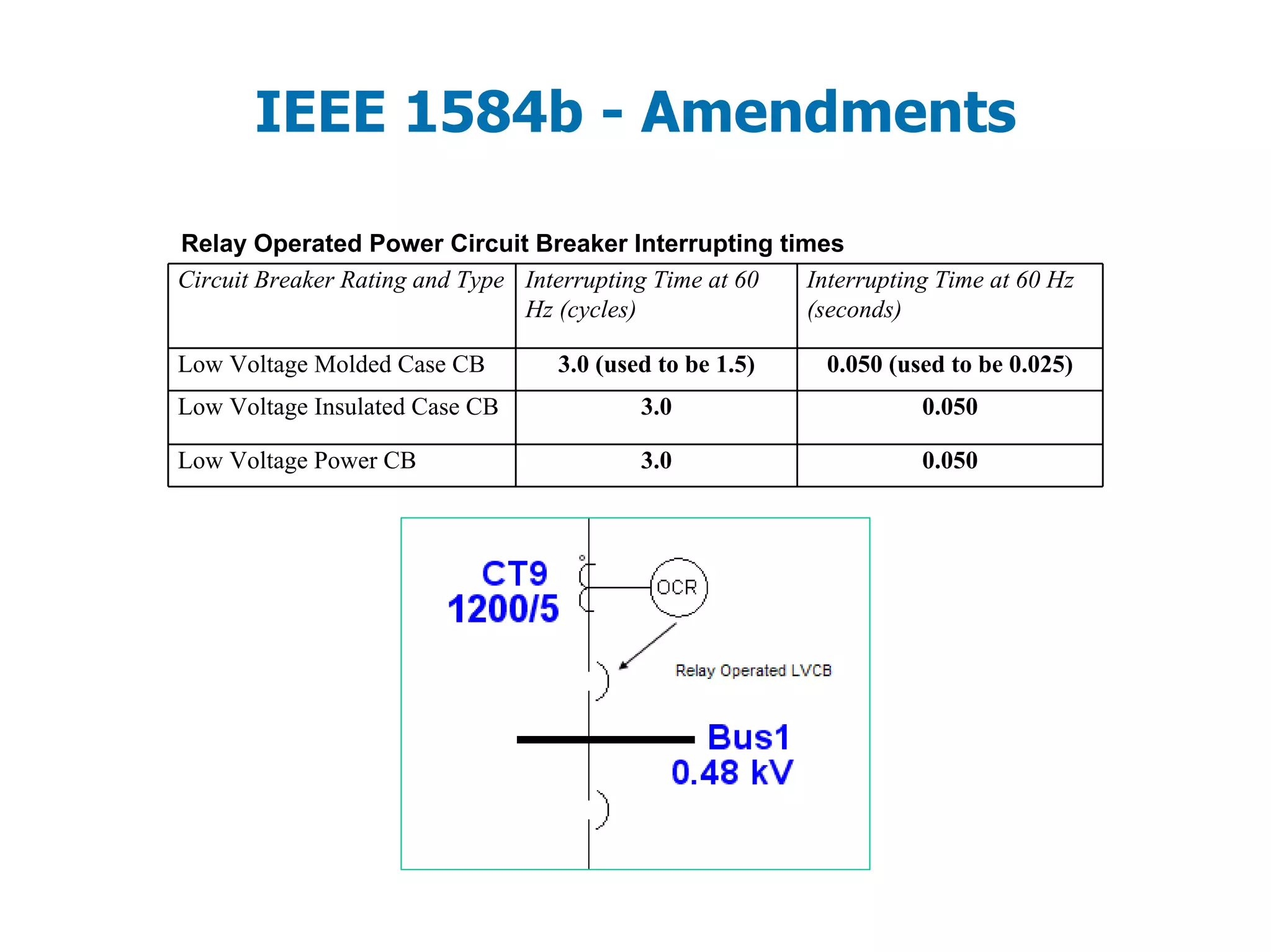

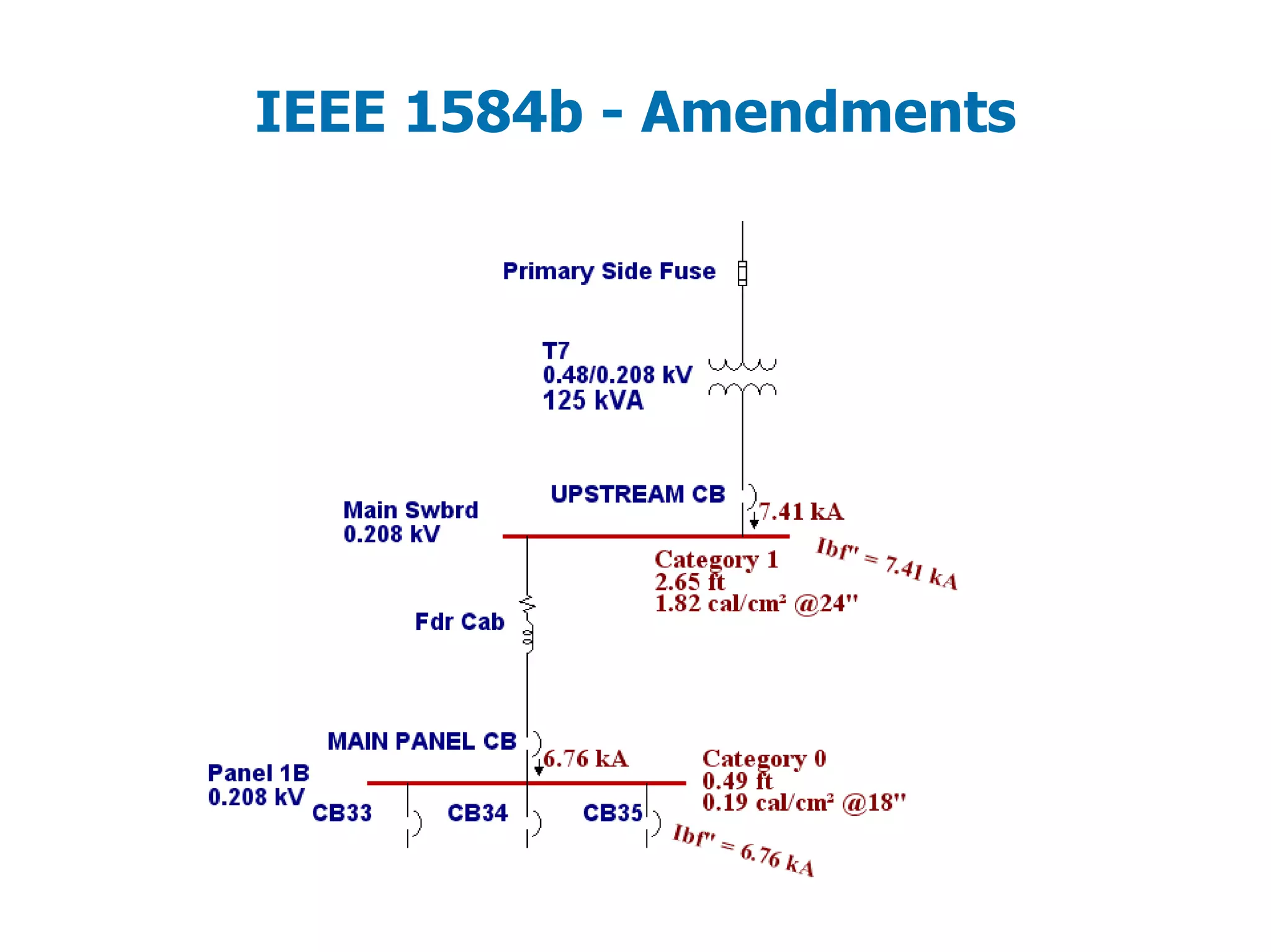

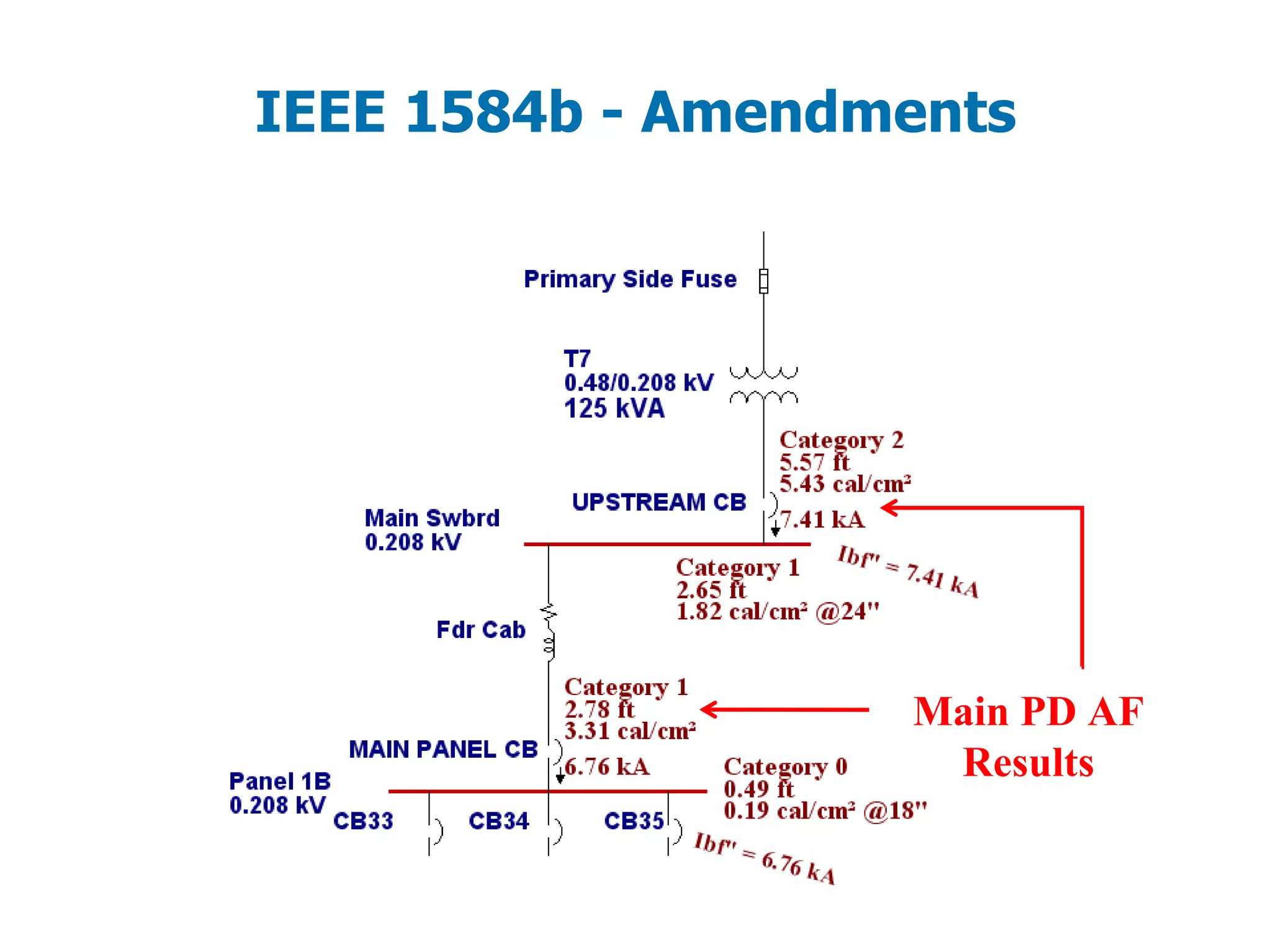

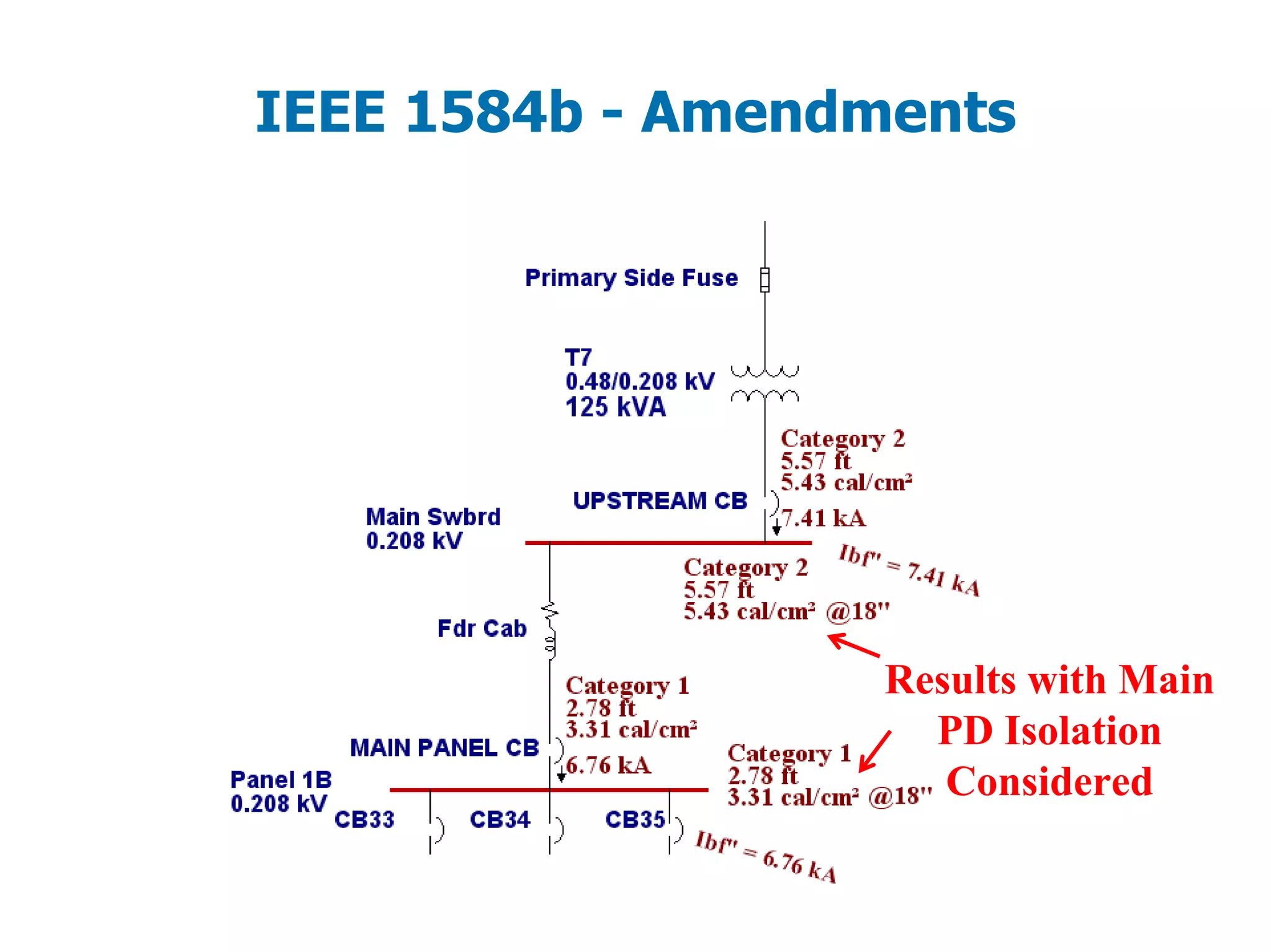

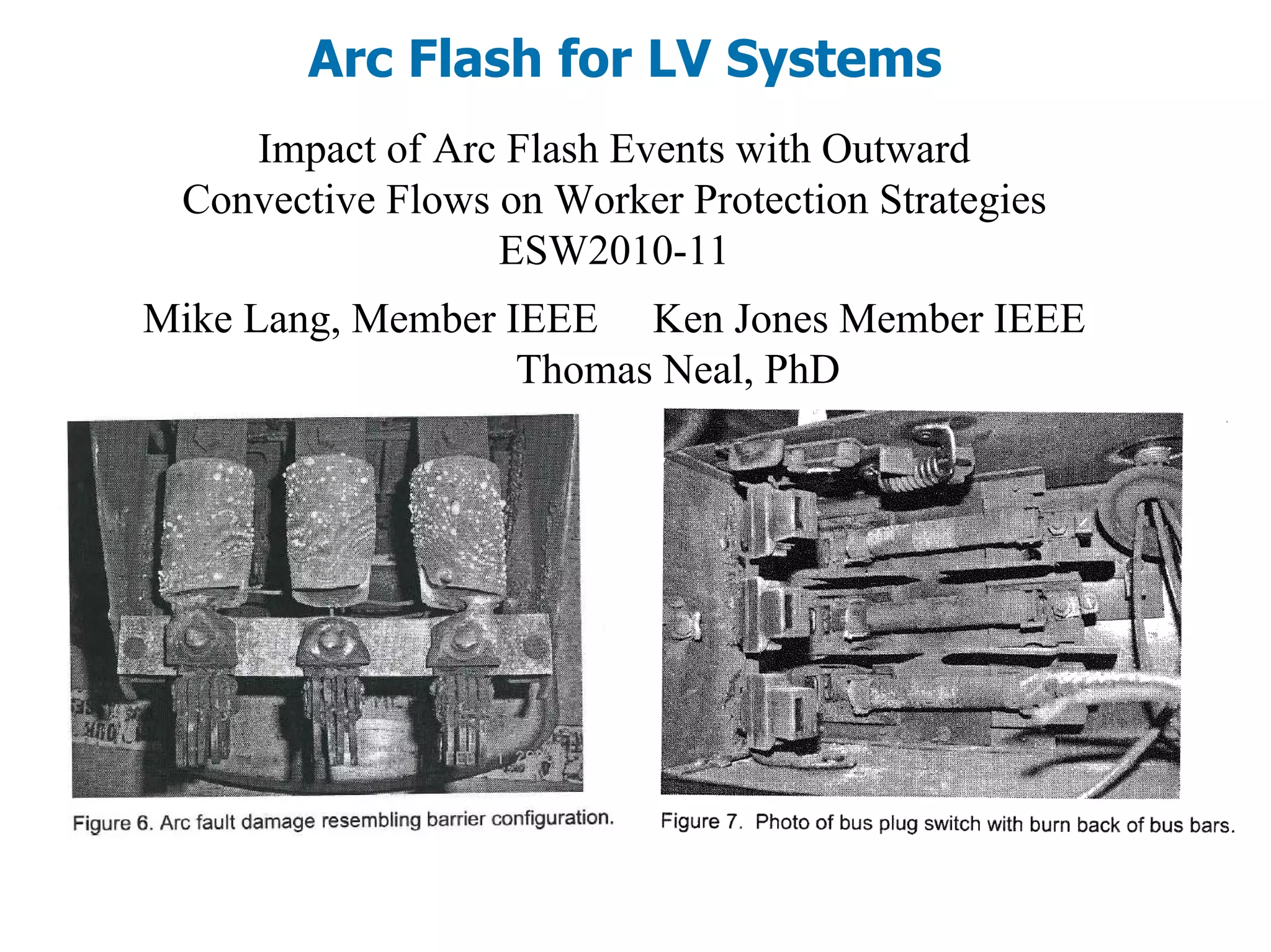

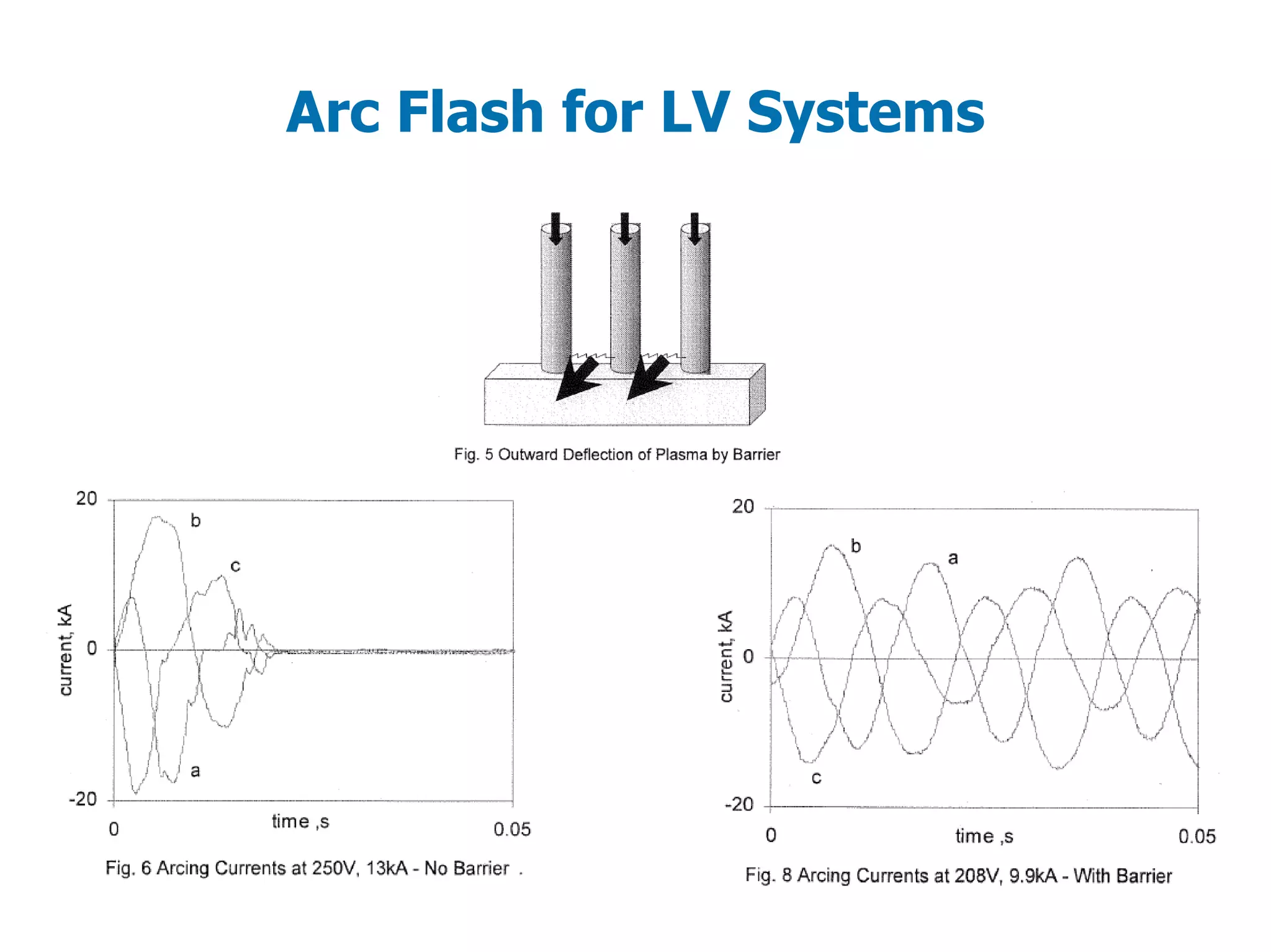

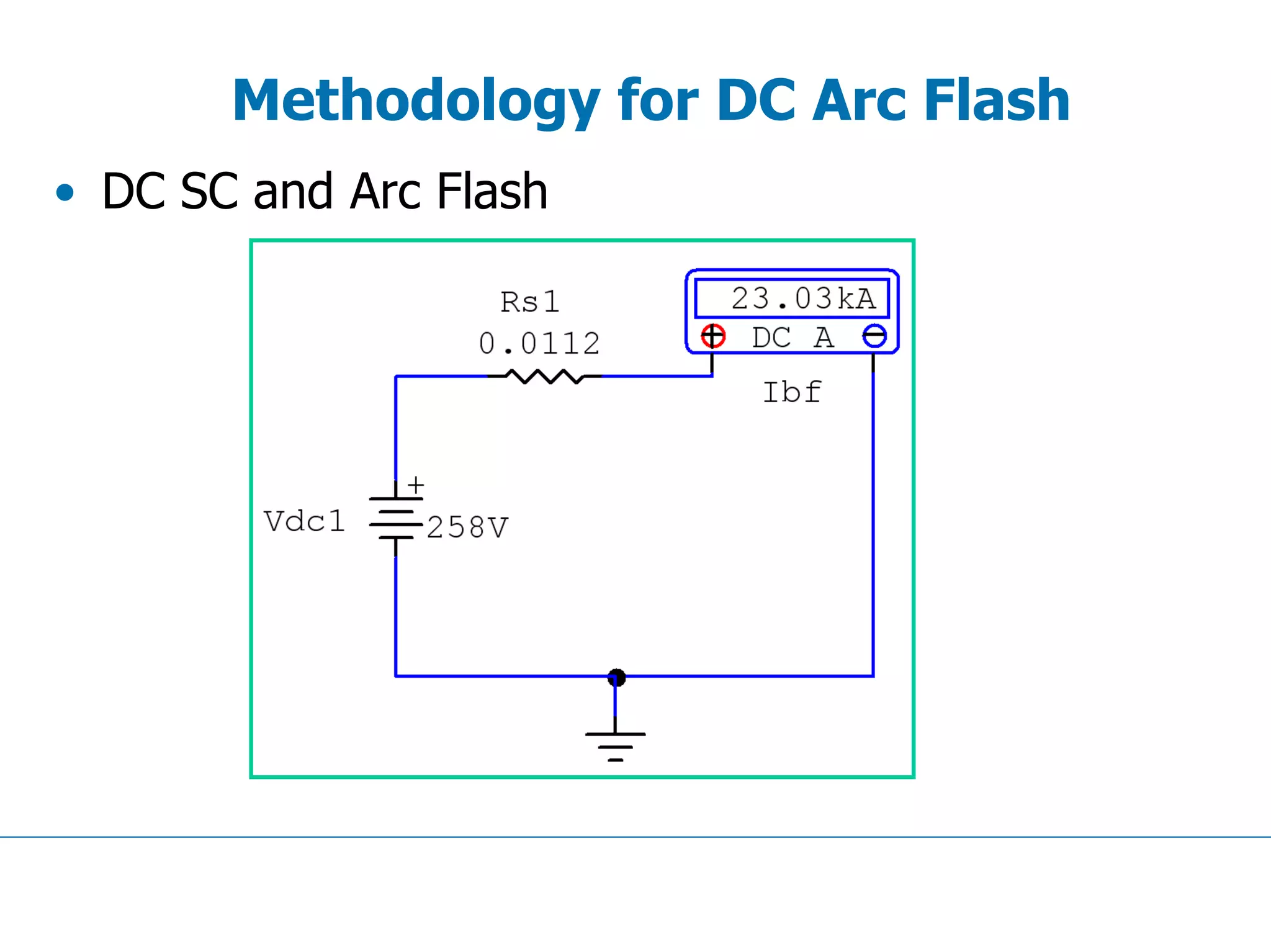

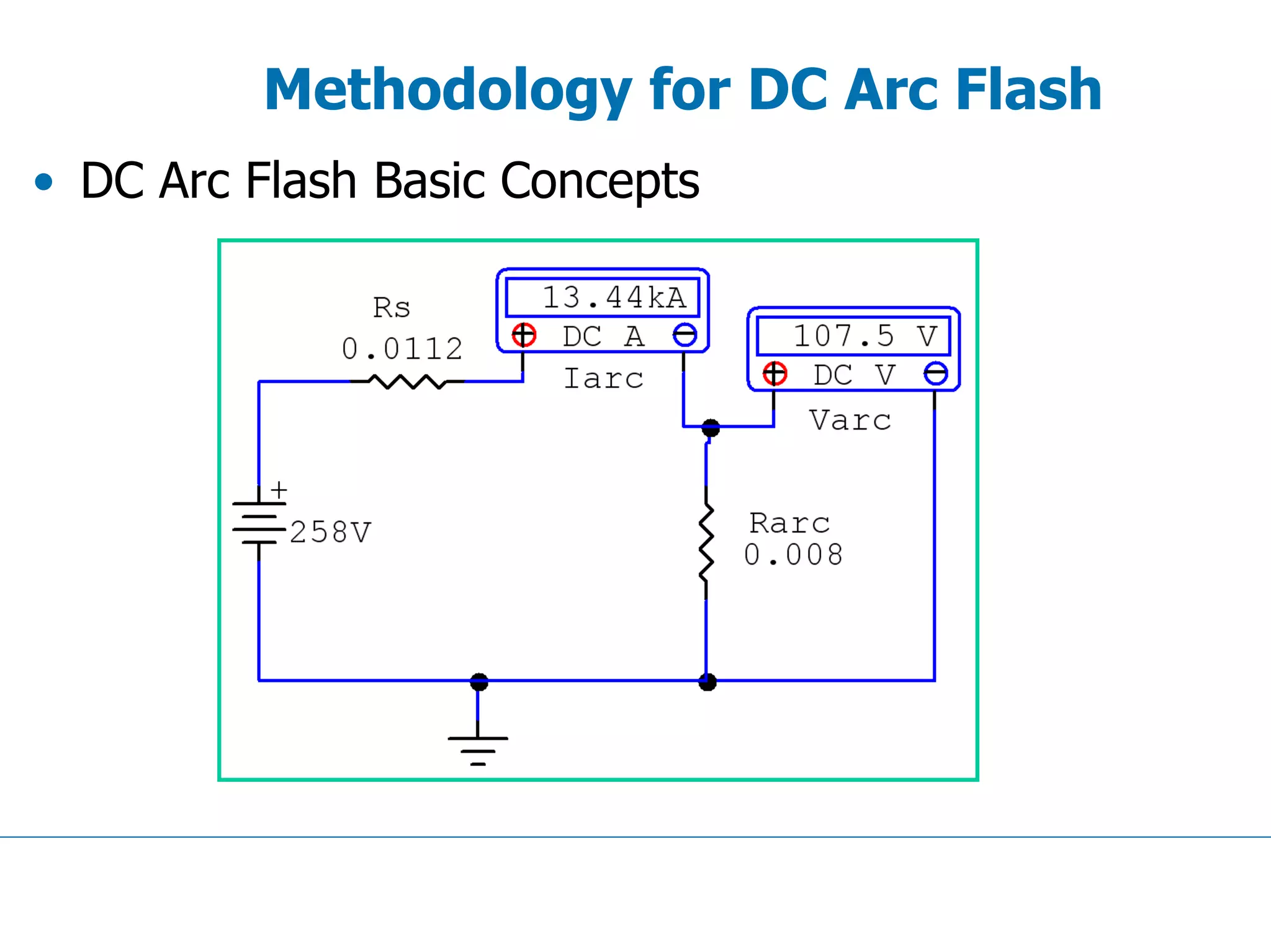

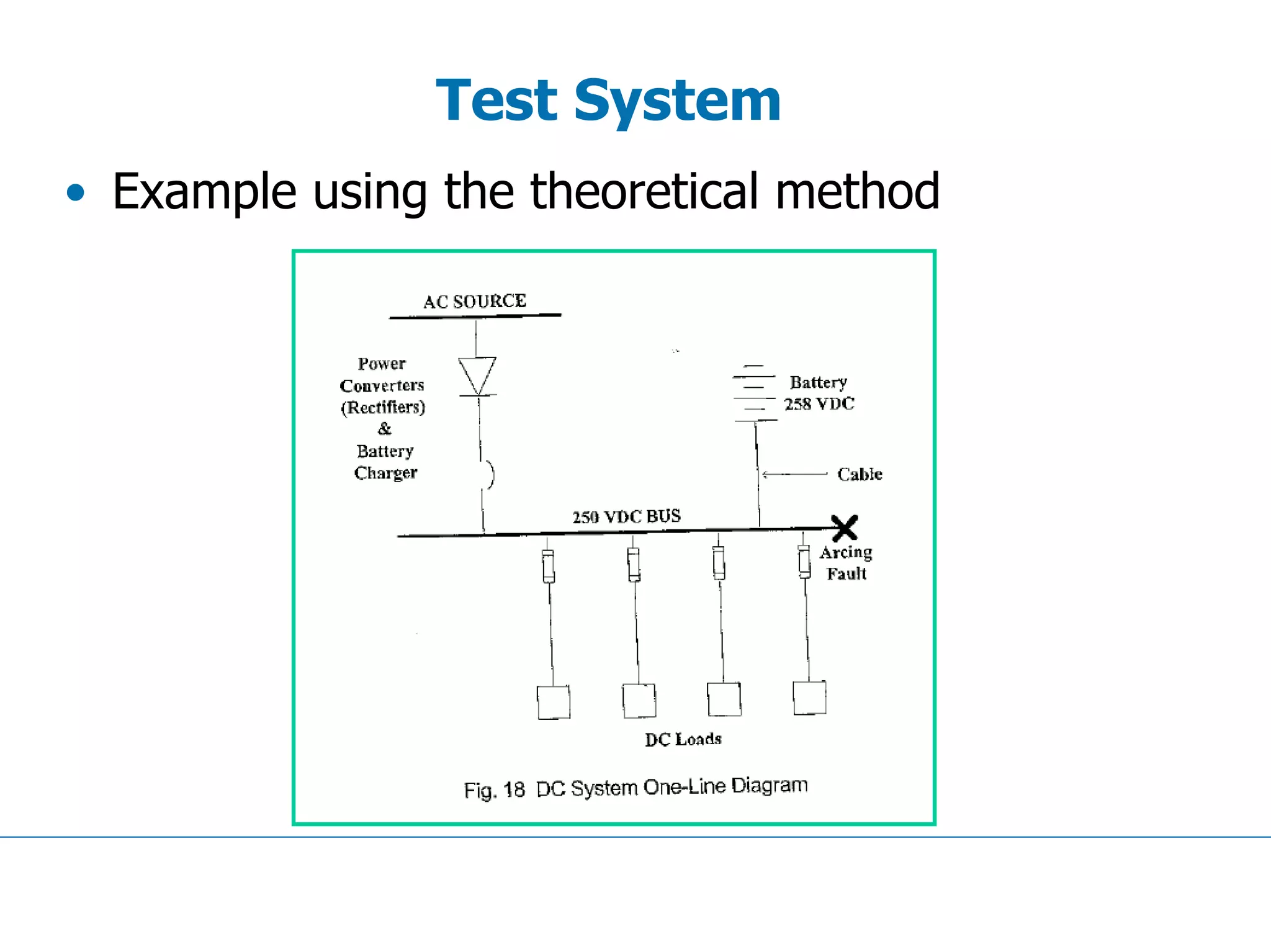

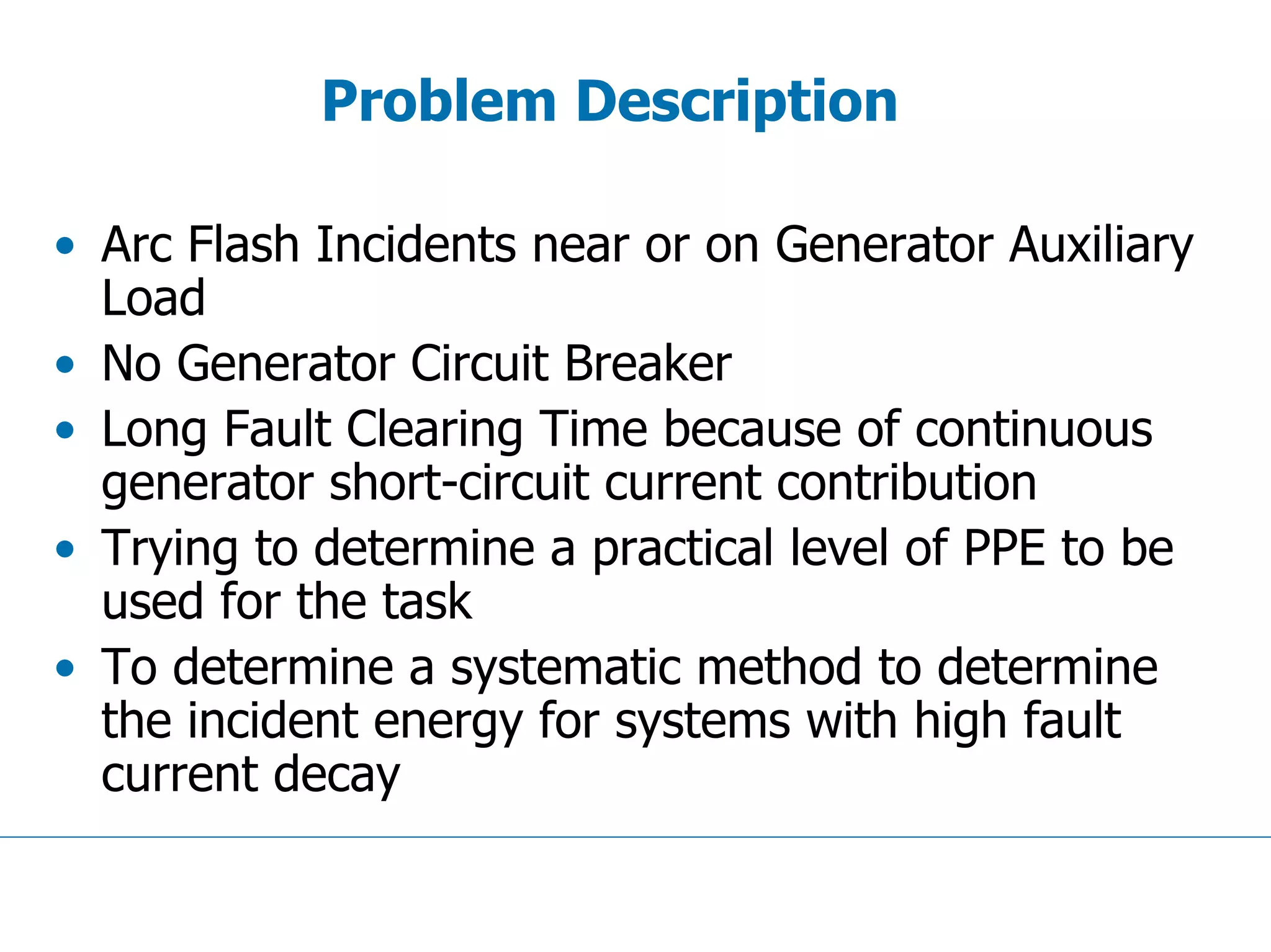

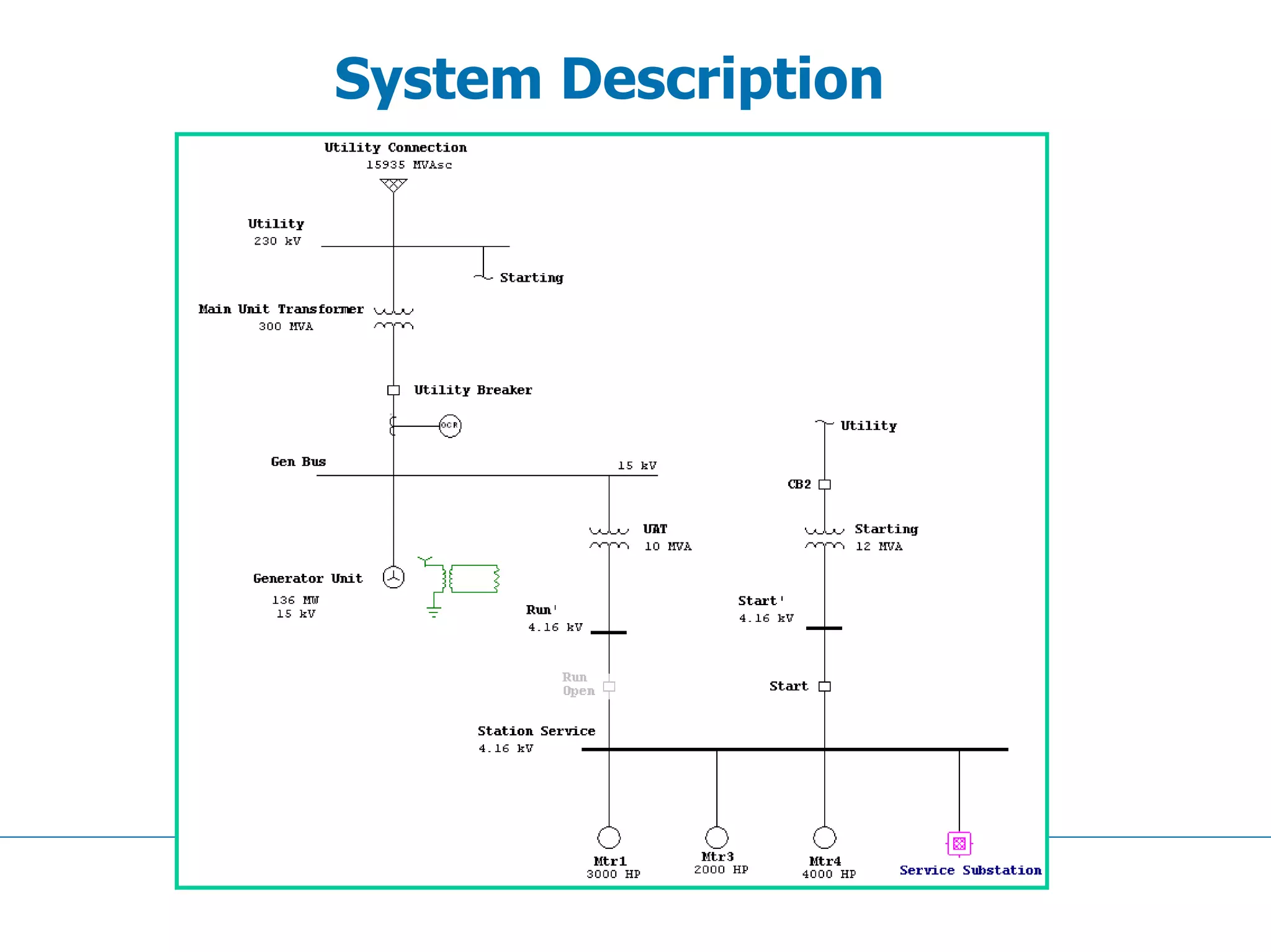

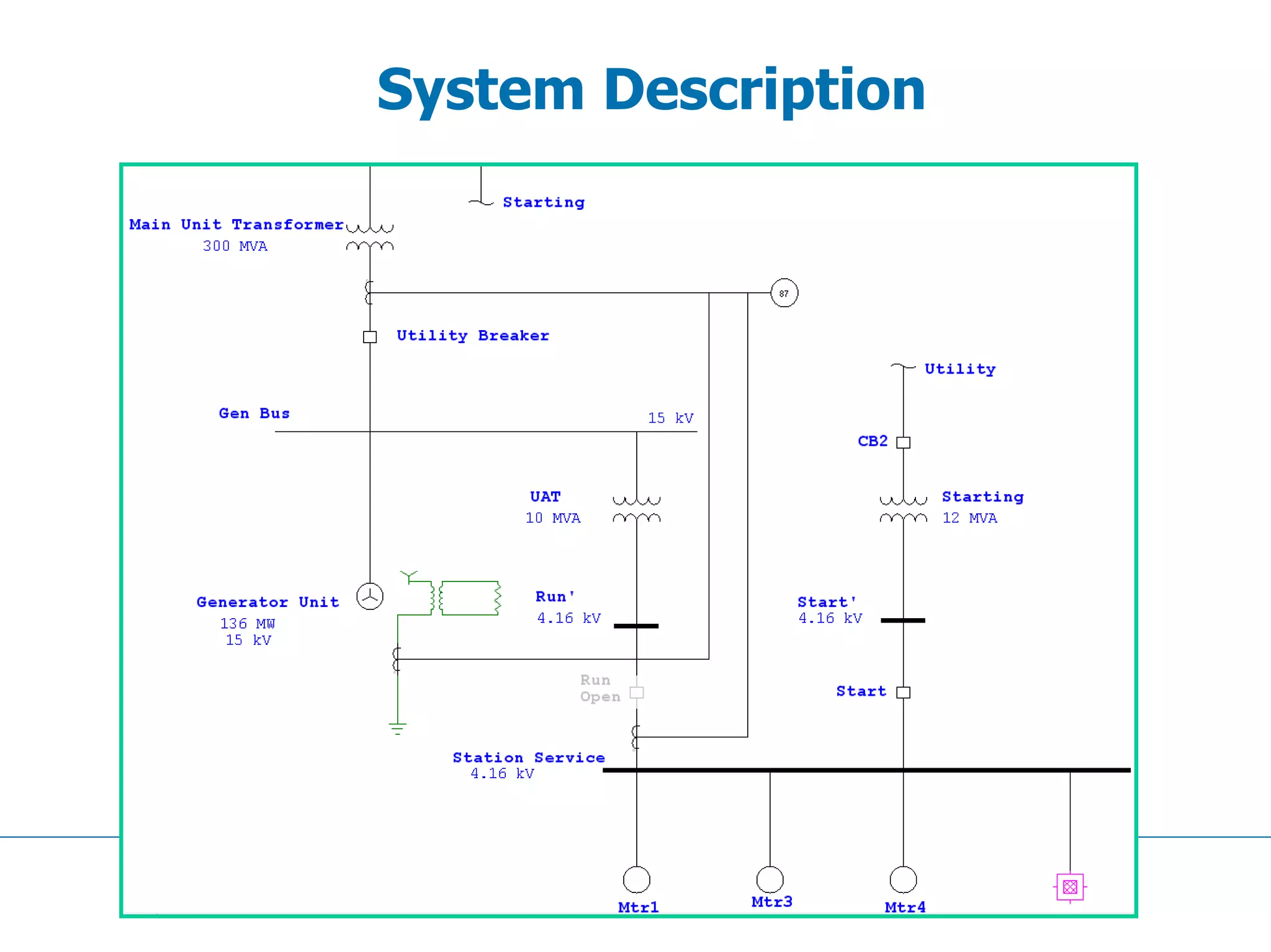

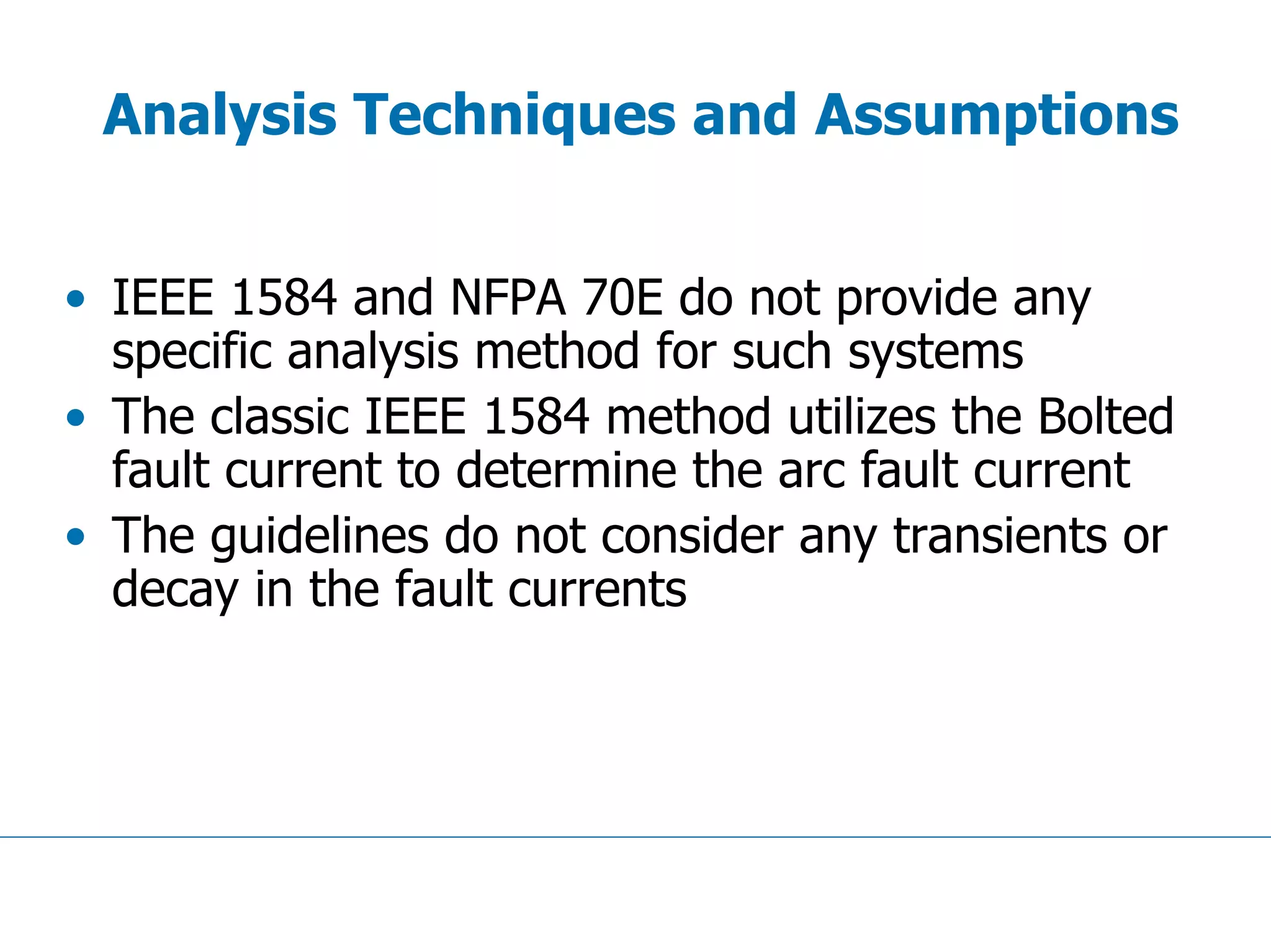

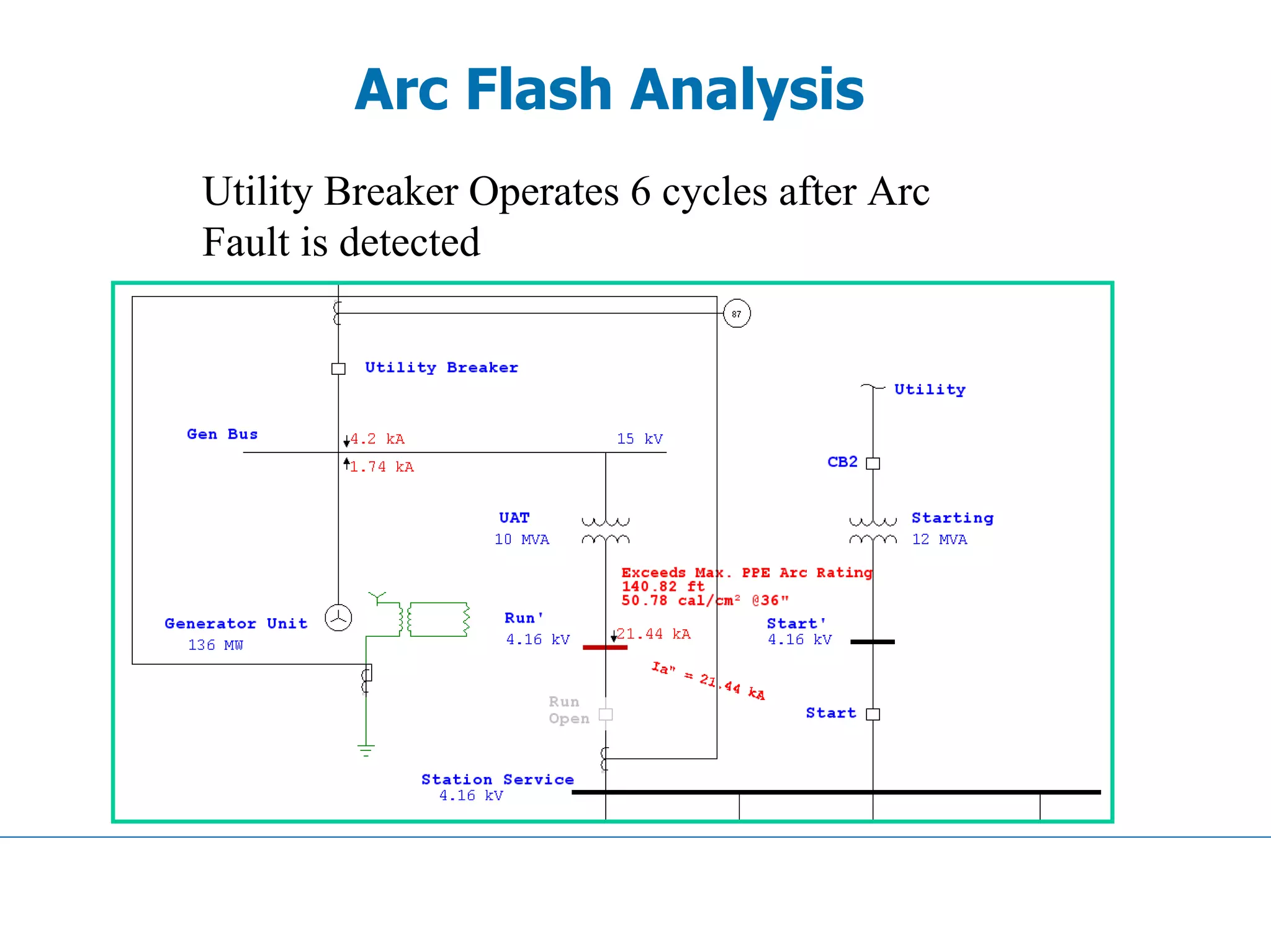

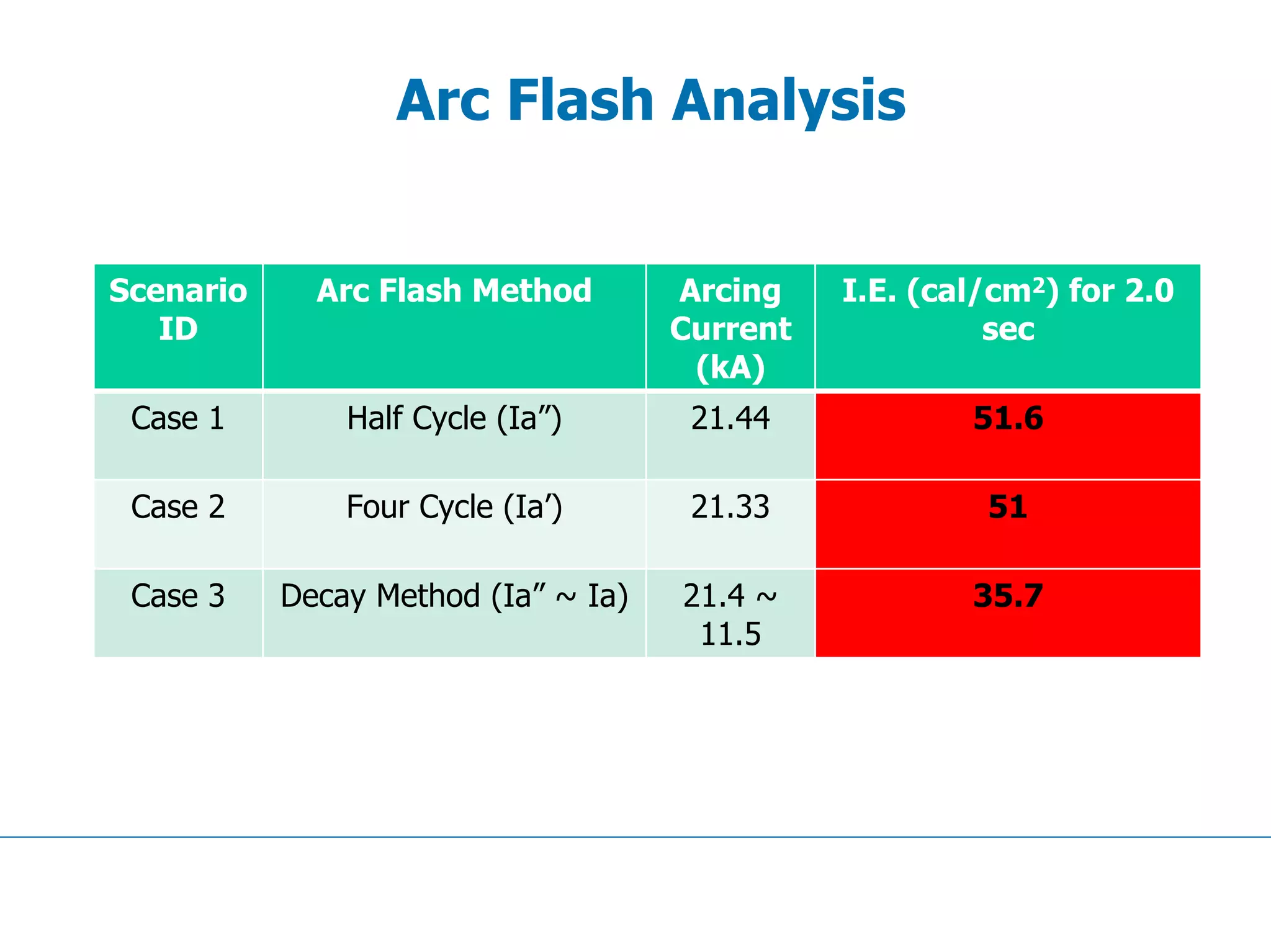

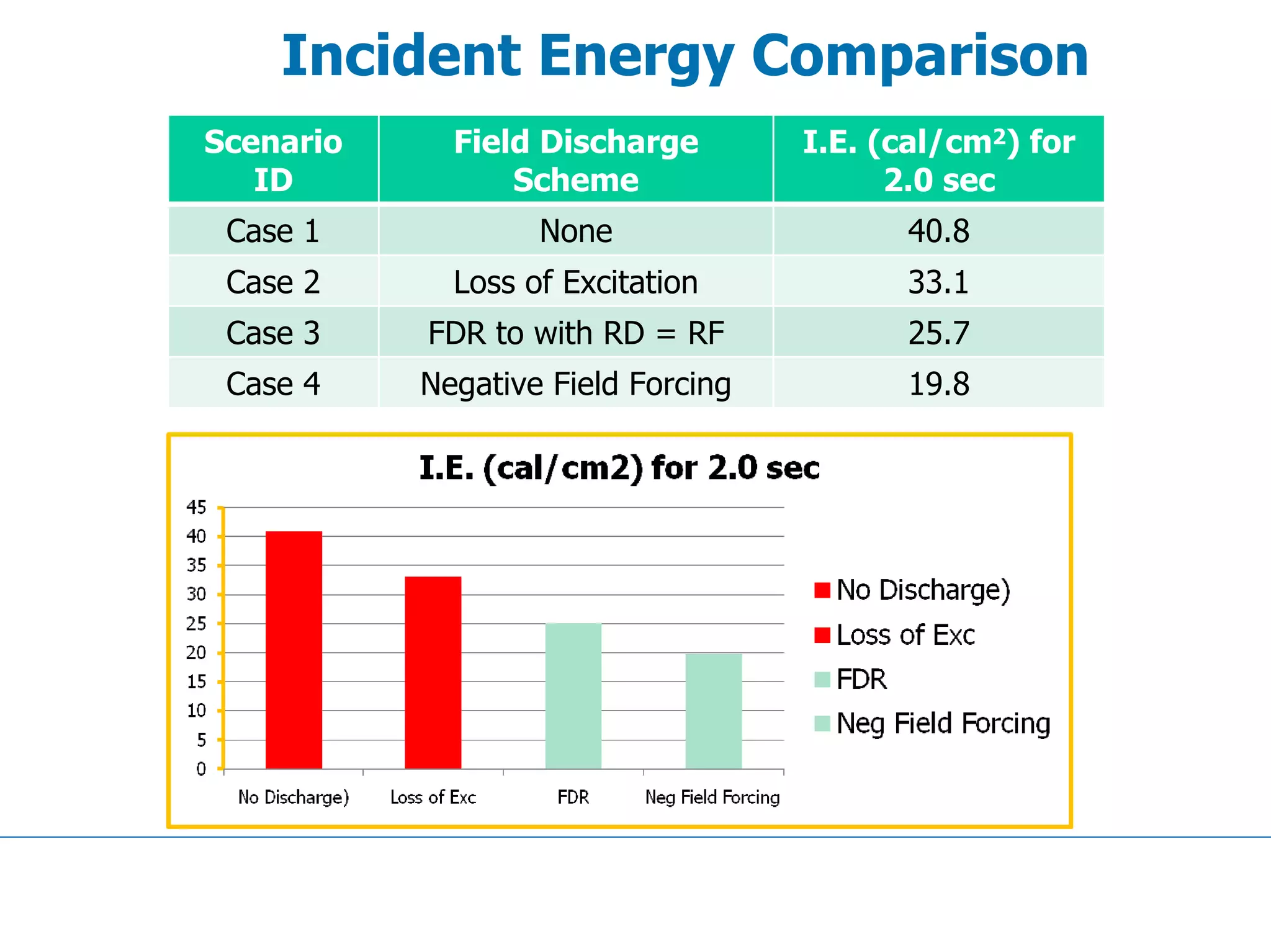

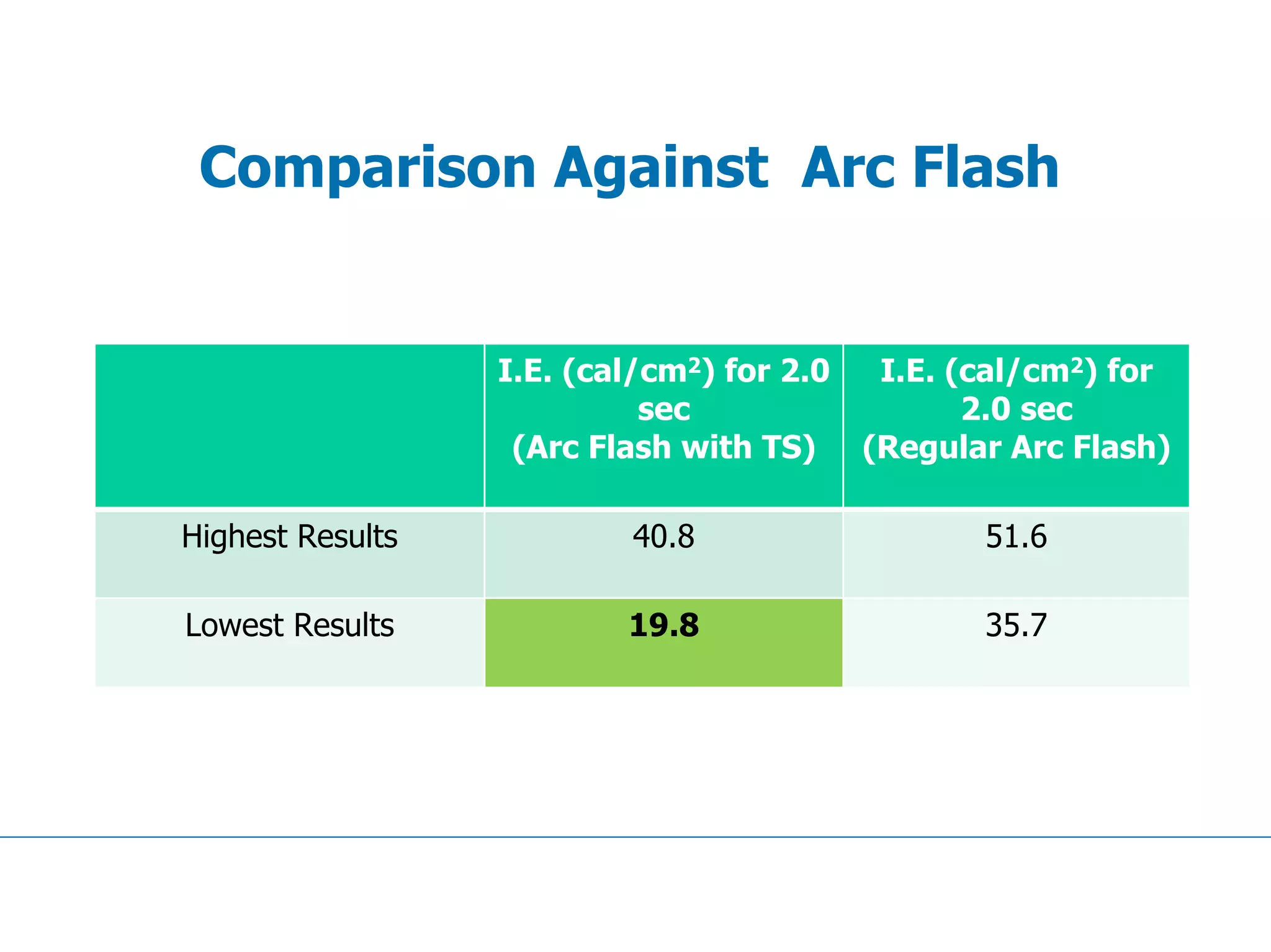

This document discusses short-circuit calculations, protective device coordination, and arc flash analysis. It covers topics such as short-circuit fault types and calculations, the purpose of short-circuit studies, system components involved, and protective device coordination principles. Methods to perform arc flash analysis and mitigate incident energy exposure are also presented, such as improving protective device coordination settings, installing current limiting fuses or circuit breakers, and using Type 50 protective devices.